Soilless greening method of building roof

An inorganic substrate and plant technology, applied in soilless cultivation, botany equipment and methods, roof decoration, etc., can solve problems such as unsatisfactory effect of fixing plant roots, unsuitable for roofless greening, flower cultivation and cumbersome management , to achieve the effect of easy penetration, easy implementation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

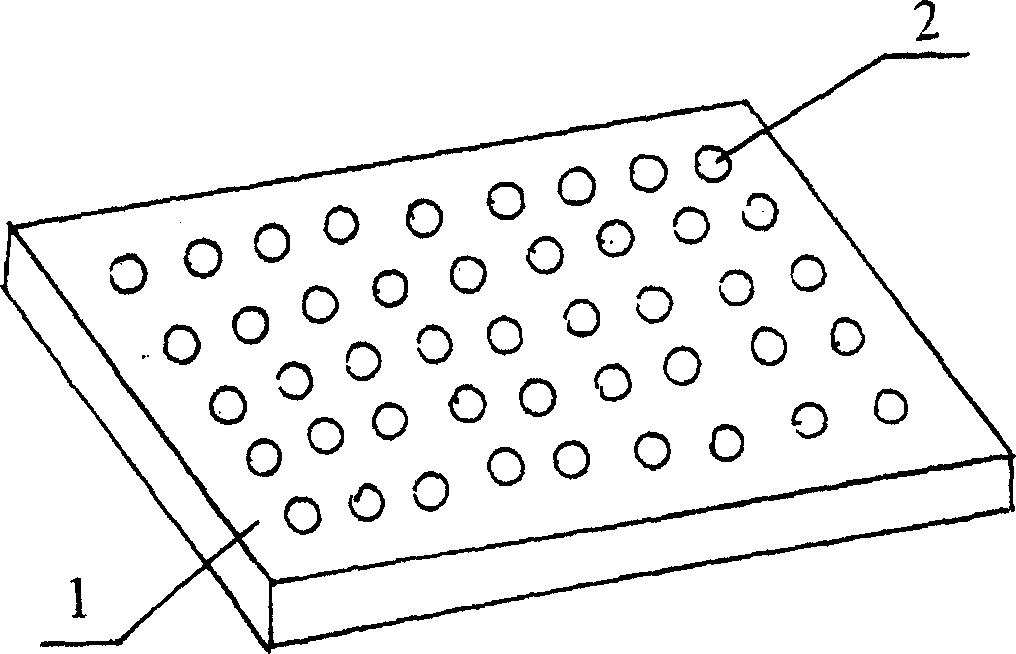

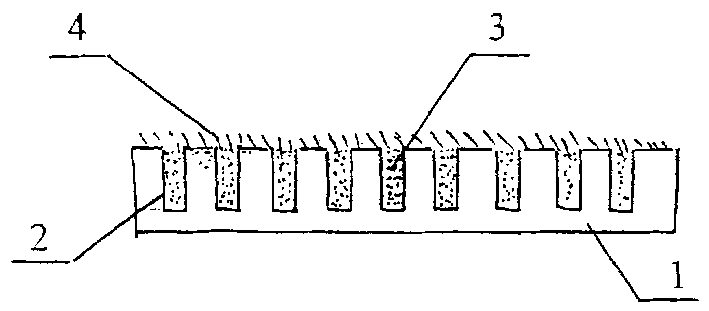

[0015] Use an area of 1m 2 , thickness is 40cm block polystyrene foam board with concave hole as carrier, with sawdust and flower fertilizer as organic matrix, is that the sand grain of 31% is made inorganic matrix with porosity, by the weight ratio of sand: sawdust: flower fertilizer is 70 : 25:5 ratio to fully mix the three into a mixed carrier, fill it into the concave hole of the carrier, spread lawn turf on the surface of the mixed carrier, spray a small amount of water, and the lawn turf will turn green after a week, and its seedlings will grow luxuriantly. Assemble several green boards.

Embodiment 2

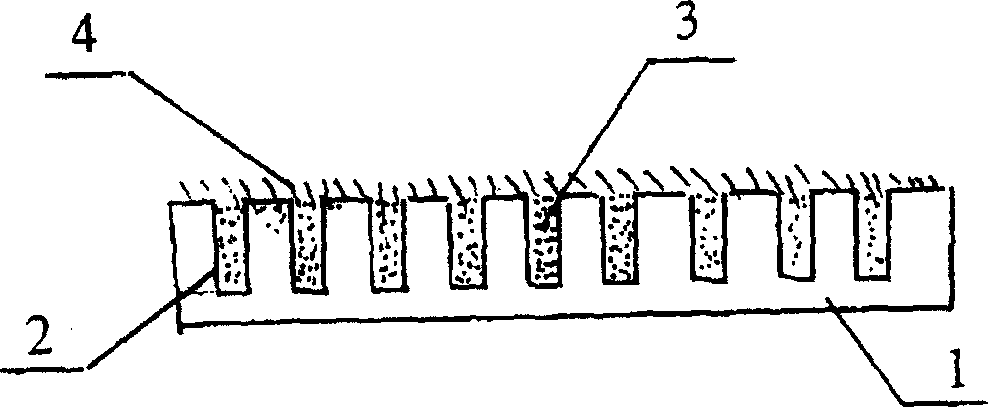

[0017] Use an area of 1m 2 , a block-shaped polystyrene foam board with grooves with a thickness of 85 cm is used as a carrier, bran, rotten leaves and flower fertilizer are used as an organic substrate, and ceramic particles with a porosity of 78% are used as an inorganic substrate, according to ceramic particles: bran : The weight ratio of rotten leaves: flower fertilizer is 94: 2: 3: 1. The four are fully mixed into a mixed carrier, which is filled in the groove of the carrier, and the seeds of "Clivia" are sprinkled on the surface of the mixed carrier. Spread a thin layer of organic substrate, spray a small amount of water, and water once every 3 days. The radicle will emerge after 12 days in an environment of 25-30°C, and the coleoptile will grow after 30 days. Pots.

Embodiment 3

[0019] Use an area of 1m 2 , a block-shaped polystyrene foam board with concave holes with a thickness of 60 cm is used as a carrier, sawdust and rotten straw are used as an organic substrate, and ceramic particles with a porosity of 83% are used as an inorganic substrate. The weight ratio is 80:15:5, the three are fully mixed into a mixed carrier, filled into the concave holes of the carrier, and the lawn turf is planted on the surface of the mixed carrier, sprayed with a small amount of water, and the lawn turf turns green after a week. The seedlings grow lushly, and several green boards are put together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com