Novel explosion-proof distribution box based on electrical automation

An electrical automation, distribution box technology, applied in the cooling/ventilation, magnetic field/electric field shielding of electrical components, substation/switchgear, etc. General performance and other issues, to improve stability and safety, prevent electromagnetic interference, and ensure the effect of explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

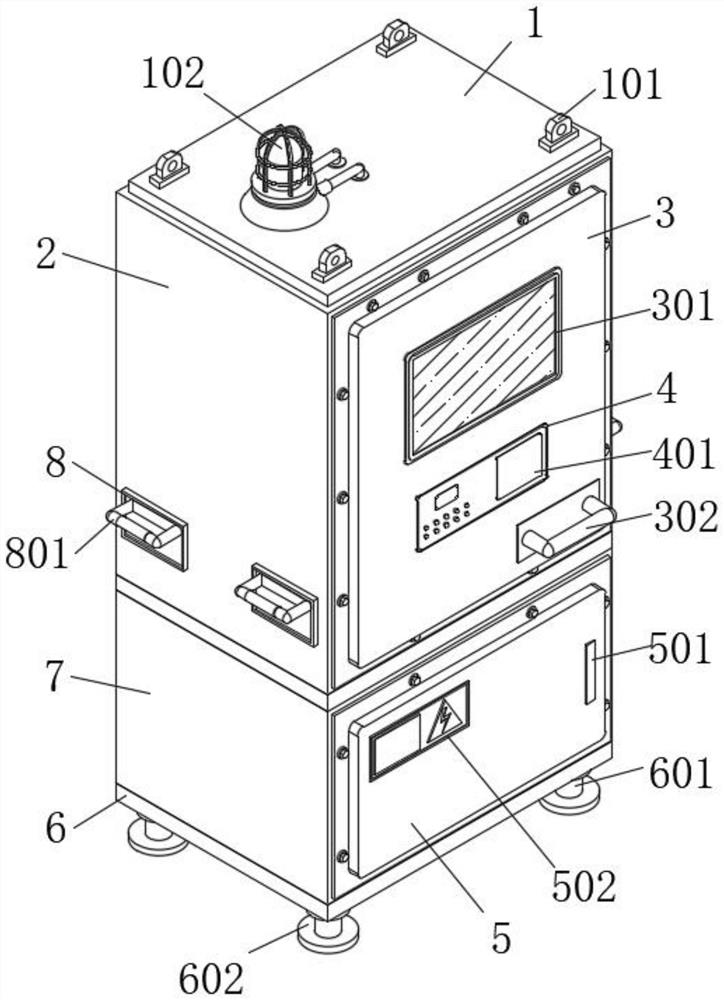

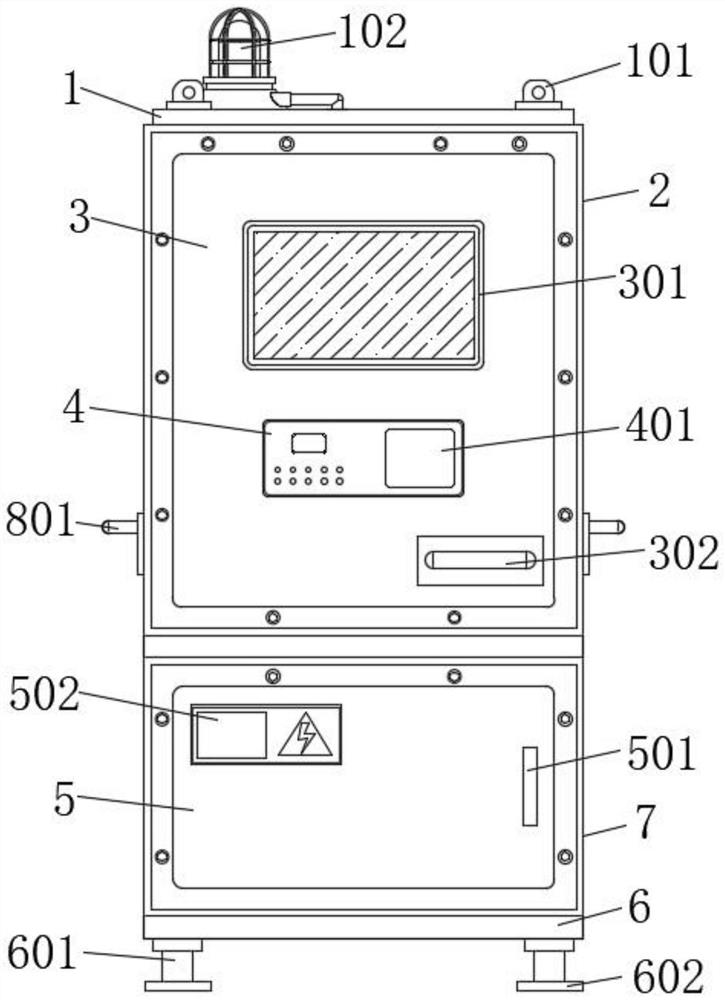

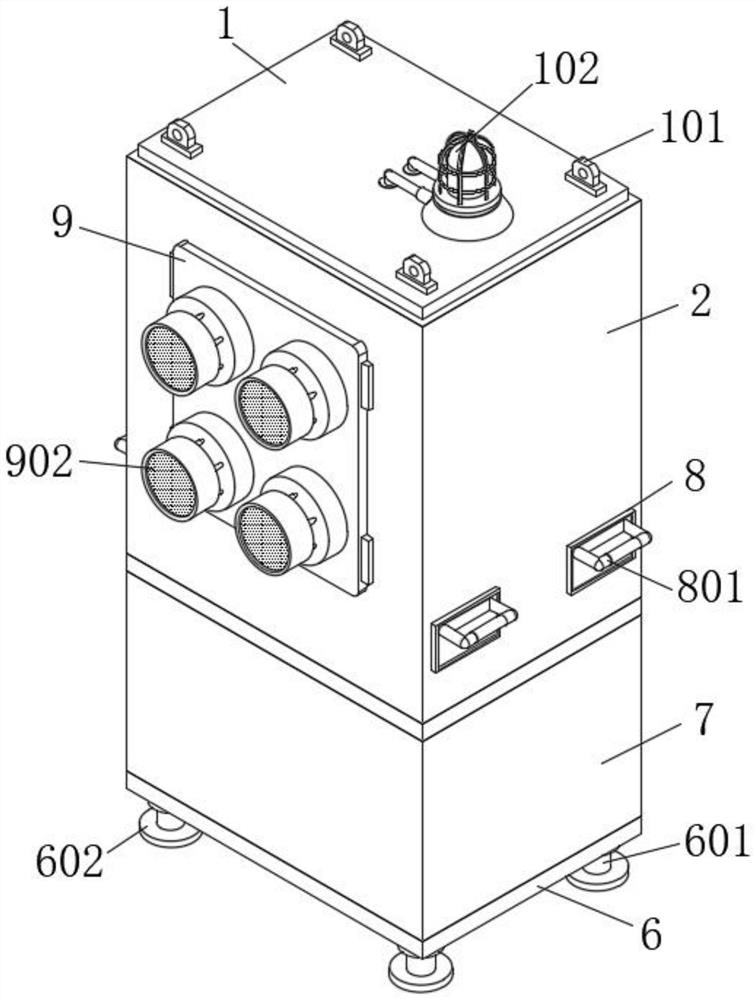

[0031] Such as Figure 1-6 As shown, a new explosion-proof distribution box based on electrical automation proposed by the present invention includes a top box 2, a base 6 and a vapor chamber 9, and a bottom box 7 is installed on the top of the base 6, and the front of the bottom box 7 passes through a hinge An explosion-proof door 5 is installed, and a top box 2 is installed on the top of the bottom box 7, and a copper plate 203 is installed inside the top box 2, and an electromagnetic shielding layer 204 is installed on one side of the copper plate 203, and the front of the top box 2 is installed by a hinge. Chamber door 3, control panel 4 is installed under the front of chamber door 3, two groups of side feet 8 are installed on the outside both sides of top box 2, top cover 1 is installed on the top of top box 2, and the back side of top box 2 is installed with Vapor plate 9 , a semiconductor cooling plate 901 is installed on the back of the heating plate 9 , and a fan 902 ...

Embodiment 2

[0034] Such as figure 1 or Figure 4As shown, the present invention proposes a new type of explosion-proof distribution box based on electrical automation. Compared with Embodiment 1, this embodiment also includes: two sets of lifting lugs 101 are installed on both sides of the top of the top cover 1, and the top cover 1 A warning light 102 is installed on one side of the top of the top box 2, a dust detector 201 is installed on the top of the top box 2, and an equipment rack 202 is installed on the inside of the top box 2 through bolts, and a window 301 is installed on the front of the box door 3, and the window A handle 302 is installed on the lower side of the front side of the 301, a digital display screen 401 is installed on the front side of the control panel 4, and buttons are installed on the other side of the front side of the control panel 4, and a door handle is installed on the front side of the explosion-proof door 5. 501, and a nameplate 502 is installed on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com