Preparation method of compound fruit and vegetable jam

A technology of fruit and vegetable jam and jam, which is applied in the direction of food ingredients as antimicrobial preservation, food science, food ingredients, etc. It can solve the problems of poor gel properties of low-sugar jams, etc., and achieve uniform, smooth, stable coatings. Enhance the effect of electrostatic repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

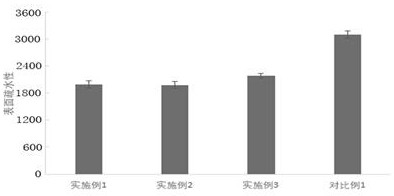

Embodiment 1

[0031] 200g of sweet potatoes, 100g of carrots, 100g of lemons, 200g of bananas and 300g of Sophora japonica are peeled and cleaned, then add 1800g of water to make a slurry until the slurry is uniform and fine without lumps; add 0.27g of pectinase to the fruit and vegetable slurry and stir well After enzymatic hydrolysis at 20°C for 3 hours; then add 200g of milk to the above fruit and vegetable slurry, after sterilizing at 75°C for 10 minutes, cool to room temperature, add 0.4% activated Saccharomyces cerevisiae, and stir at 25°C at a speed of 150 rpm Fermentation for 6 days. At this time, the alcohol content in the fermentation mixture was 13.2%, and the content of free total flavonoids was 22.5 mg / g (when determining the total flavonoid content, directly sample and measure without further extraction). Then the fermented product was boiled at 55°C to obtain jam, and the soluble solid content at the end of the boil was 50%; the jam was put into a screw-top glass bottle steri...

Embodiment 2

[0033] 300g of sweet potatoes, 200g of carrots, 300g of lemons, 300g of bananas and 600g of Sophora japonica are peeled and cleaned, then add 6800g of water to make a slurry until the slurry is uniform and fine without lumps; add 2.55g of pectinase to the fruit and vegetable slurry and stir well After enzymolysis at 20°C for 5 hours; then add 400g of milk to the above fruit and vegetable slurry, after sterilizing at 90°C for 10 minutes, cool to room temperature, add 0.7% activated Saccharomyces cerevisiae, and stir at 30°C at a speed of 200 rpm Fermented for 8 days. At this time, the alcohol content in the fermentation mixture was 14.7%, and the content of free total flavonoids was 23.2 mg / g (when determining the total flavonoid content, directly sample and measure without further extraction). Then the fermented product was boiled at 60°C to obtain jam, and the soluble solid content at the end of the boil was 53%; the jam was put into a screw-top glass bottle sterilized by boi...

Embodiment 3

[0035] 260g of sweet potatoes, 130g of carrots, 210g of lemons, 220g of bananas and 430g of Sophora japonica are peeled and cleaned, then add 3750g of water to make a slurry until the slurry is uniform and fine without lumps; add 1g of pectinase to the fruit and vegetable slurry, stir well Enzymolysis at 22°C for 4 hours; then add 360g of milk to the above fruit and vegetable slurry, after sterilizing at 85°C for 13 minutes, cool to room temperature, add 0.5% activated Saccharomyces cerevisiae, and stir and ferment at 28°C at 220 rpm 9 days. At this time, the alcohol content in the fermentation mixture was 12.8%, and the content of free total flavonoids was 22.9 mg / g (when determining the total flavonoid content, directly sample and measure without further extraction). Then the fermented product was boiled at 62°C to obtain jam, and the soluble solid content at the end of the boil was 52%; the jam was put into a screw-top glass bottle sterilized by boiling water, sealed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com