Double-rail transportation system for outdoor vertical hoisting of building

A transportation system and building room technology, which is applied in the field of horizontal transportation and vertical transportation of construction projects connected with each other, can solve problems such as safety accidents, and achieve the effects of reducing direct costs, increasing speed, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

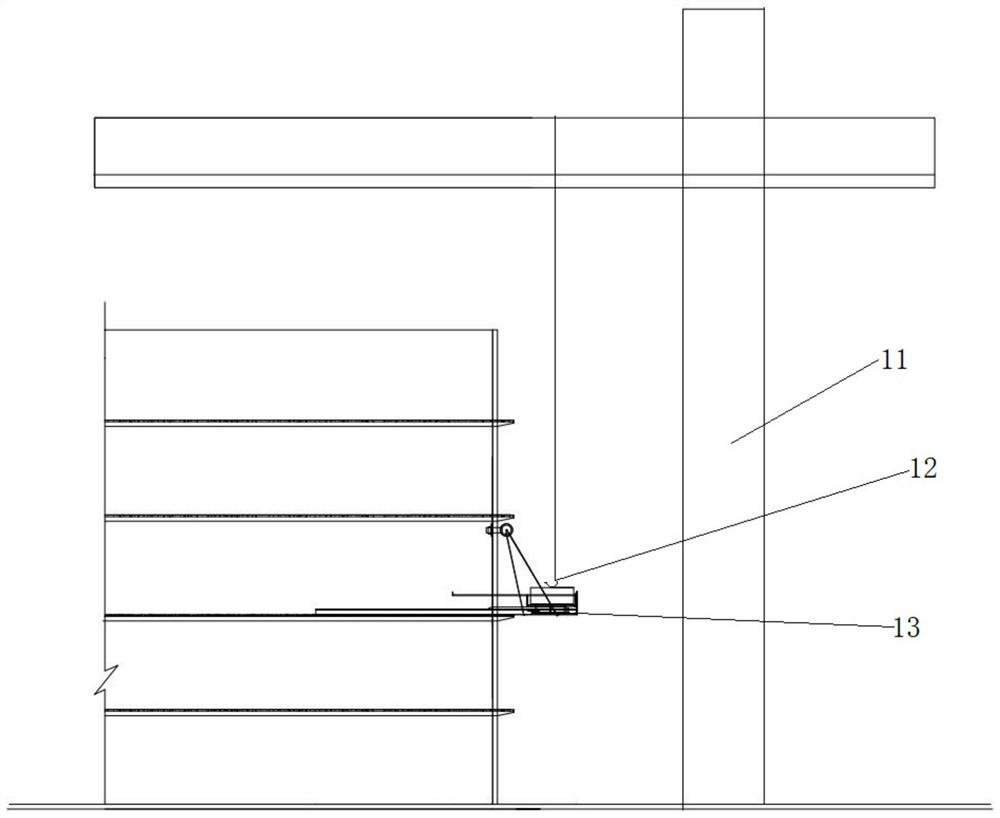

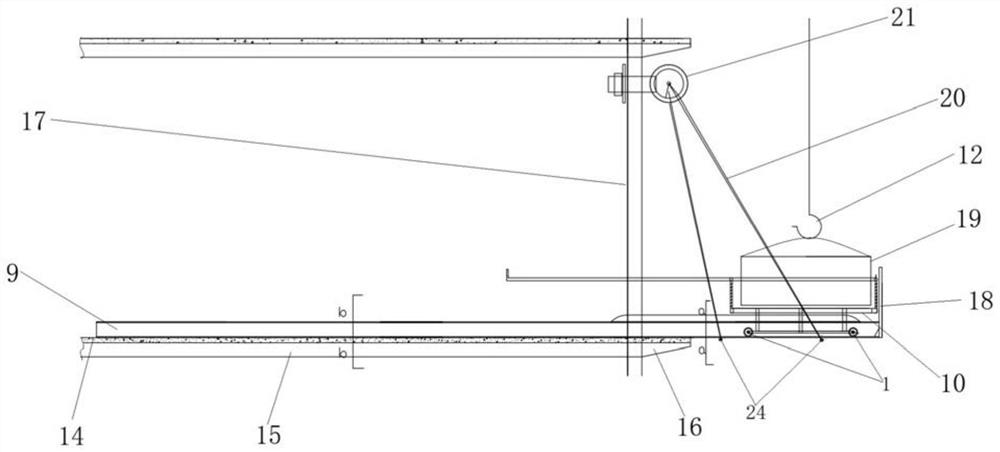

[0065] This embodiment discloses a double-track transportation system for vertical lifting outside the building, see the attached figure 1 , applicable to building structure I, which is a frame column group structure, including: floor slab 14, indoor frame beam 15, outdoor frame beam 16 and peripheral column 17;

[0066] Described dual-track transportation system comprises tower crane 11, suspension hook 12 and transportation structure 1;

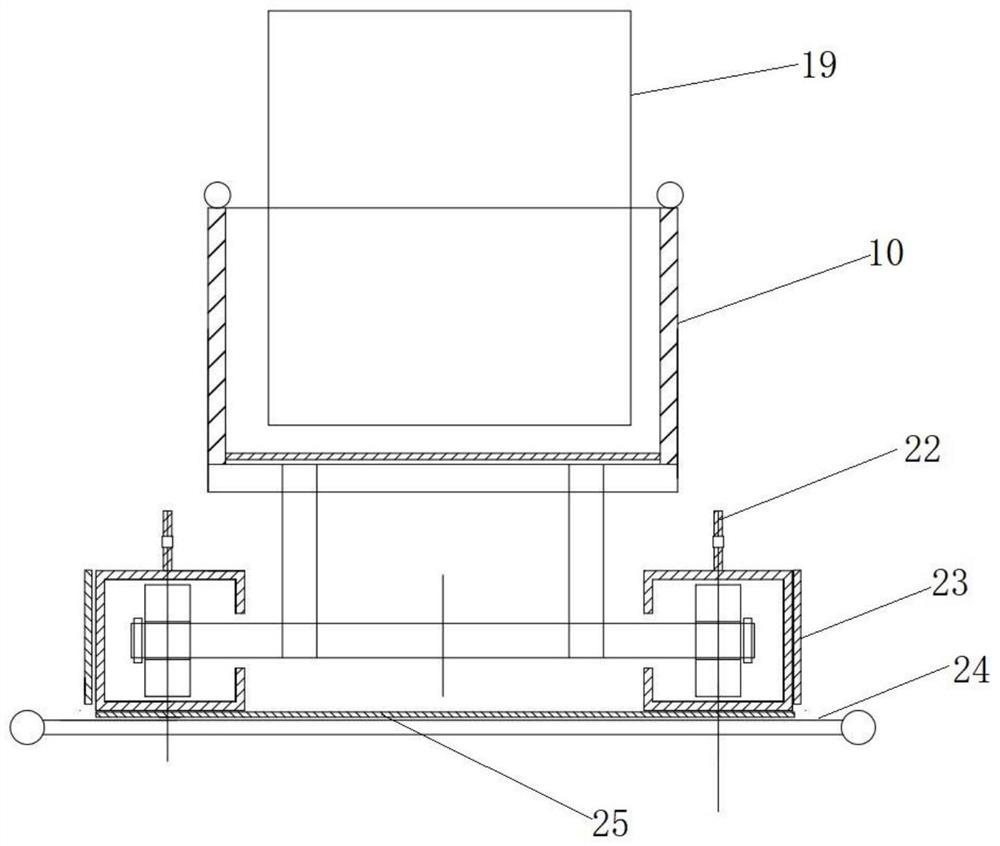

[0067] The transport structure I includes double-track C-shaped steel 9, a transport vehicle 10, a limit baffle 18, a container 19, a C-shaped steel fixing assembly 1 and a C-shaped steel reinforcement assembly;

[0068] The double-track C-shaped steel 9 is two C-shaped steel rails parallel to each other. The C-shaped openings of the two C-shaped steel rails are opposite to each other. They extend from the indoor floor 14 of the building structure to the outdoor suspended setting. The double-track C-shaped steel 9 is fixed by the C-shaped s...

Embodiment 2

[0090] This embodiment discloses a double-track transportation system for vertical lifting outside the building, see the attached Figure 11 , applicable to building structure II, which is a frame-shear wall structure, including: floor slab 14, balcony hoarding 29, window opening 30 and shear wall 31;

[0091] The dual-track transportation system includes a tower crane 11, a hook 12 and a transportation structure II 28;

[0092] The transportation structure II28 includes: double-track C-shaped steel 9, transport vehicle 10, limit baffle 18, container 19, C-shaped steel fixing component II and C-shaped steel reinforcing component;

[0093] Among them, the structural composition and connection relationship of the double-track C-shaped steel 9, the transport vehicle 10, the limit baffle 18, the container 19 and the C-shaped steel reinforcement assembly are the same as those in Embodiment 1, and will not be repeated here;

[0094] The height of the double-track C-shaped steel 9 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com