Refining method for reducing content and smell of benzyl halide in benzyl ether

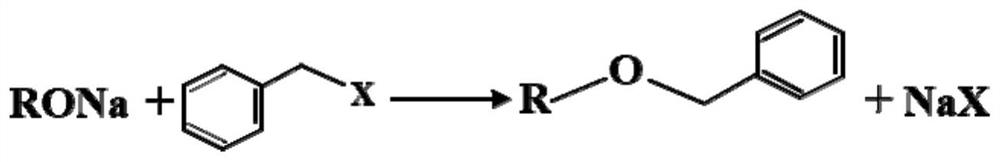

A refining method and technology of benzyl ether, applied in ether preparation, chemical instruments and methods, ether separation/purification, etc., can solve the problems of benzyl ether with strong odor, increased safety hazards, high equipment requirements, etc., to eliminate odor and simplify Refined operation, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A refining method for reducing benzyl halide content and odor in benzyl ether, comprising the following steps:

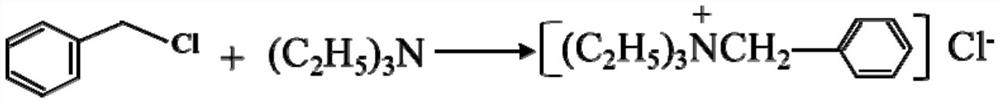

[0036] S1. Add 97 g of triethylamine (0.48 mol) solution with a mass concentration of 50% to 1410 g of the crude benzyl ether product after the etherification reaction (the capping rate is calculated as 90%, containing 0.4 mol of benzyl chloride), and start stirring , reflux reaction at 60°C for 2 hours;

[0037] S2, after the heat preservation is finished, let it stand for stratification, the upper layer liquid is the crude product, and the lower layer water phase is separated from the system and recovered to obtain an aqueous solution containing the phase transfer catalyst benzyltriethylammonium chloride;

[0038] S3, add 3.26g neutralizing agent phosphoric acid aqueous solution (mass percentage concentration 50%) to make pH=4 in upper layer liquid, then add adsorbent magnesium silicate 14g, filter aid diatomite 7g, refine under 100 ℃, 10mbar After filtrat...

Embodiment 2

[0041] A refining method for reducing benzyl halide content and odor in benzyl ether, comprising the following steps:

[0042] S1. Add 95 g of triethylamine (0.42 mol) solution with a mass concentration of 45% to 1280 g of crude benzyl ether after the etherification reaction (the capping rate is calculated as 90%, containing 0.3 mol of benzyl bromide), and start stirring , reflux reaction at 70°C for 1.5h;

[0043] S2, after the heat preservation is finished, let it stand for stratification, the upper layer liquid is the crude product, and the lower layer water phase is separated from the system and recovered to obtain an aqueous solution containing the phase transfer catalyst benzyltriethylammonium bromide;

[0044] S3, add 2.72g neutralizing agent phosphoric acid aqueous solution (mass percentage concentration 50%) to make pH=3.8 to upper layer liquid, then add adsorbent magnesium silicate 12g, filter aid diatomite 6g, refine under 100 ℃, 10mbar After filtration, the refine...

Embodiment 3

[0047] A refining method for reducing benzyl halide content and odor in benzyl ether, comprising the following steps:

[0048] S1. Add 48 g of triethylamine (0.28 mol) solution with a mass concentration of 60% to 1670 g of crude benzyl ether after the etherification reaction (the capping rate is calculated as 90%, containing 0.2 mol of benzyl chloride), and start stirring , reflux reaction at 65°C for 3 hours;

[0049] S2, after the heat preservation is finished, let it stand for stratification, the upper layer liquid is the crude product, and the lower layer water phase is separated from the system and recovered to obtain an aqueous solution containing the phase transfer catalyst benzyltriethylammonium chloride;

[0050] S3, add 3.08g neutralizing agent phosphoric acid aqueous solution (mass percentage concentration 50%) to make pH=4.2 in upper layer liquid, then add adsorbent magnesium silicate 16g, filter aid diatomite 8g, refine under 100 ℃, 10mbar After filtration, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com