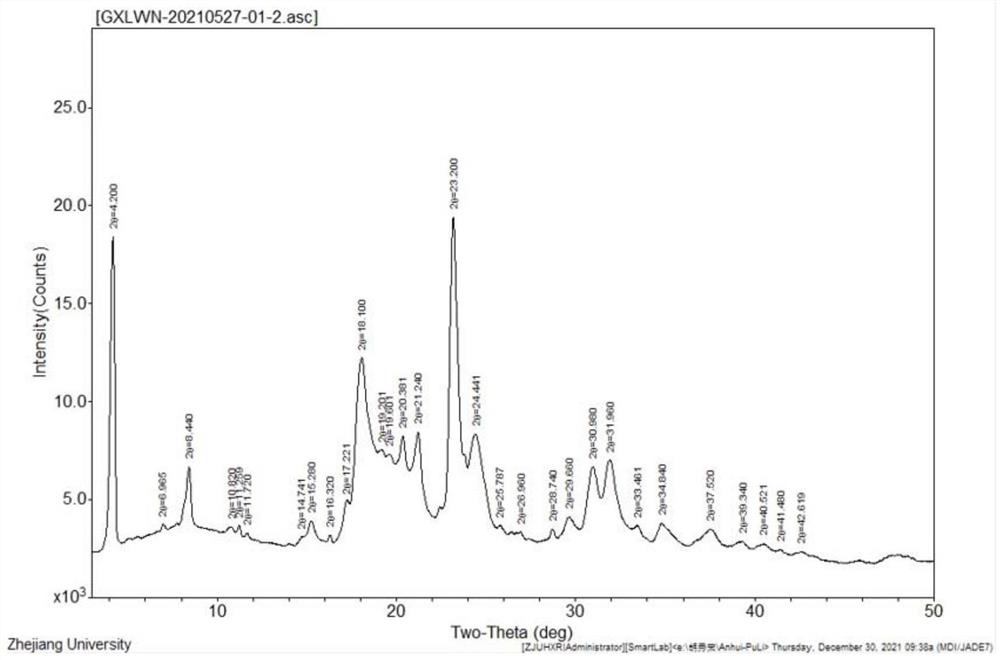

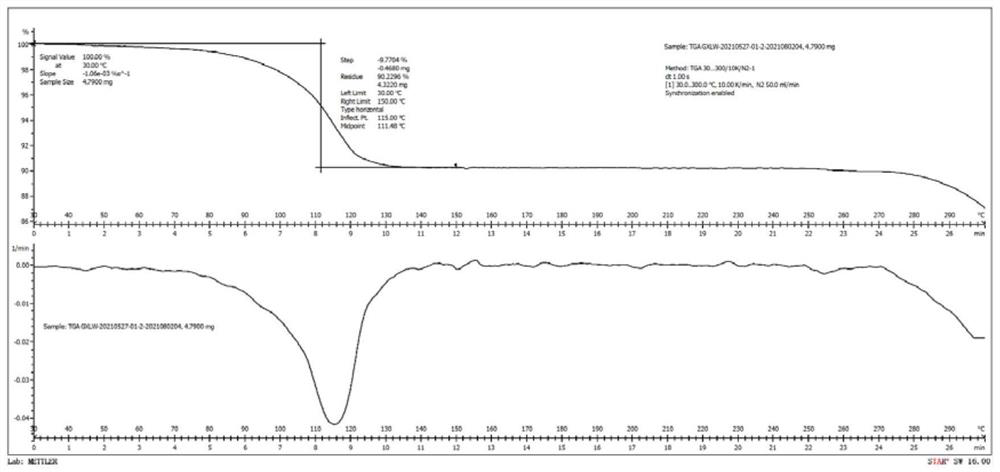

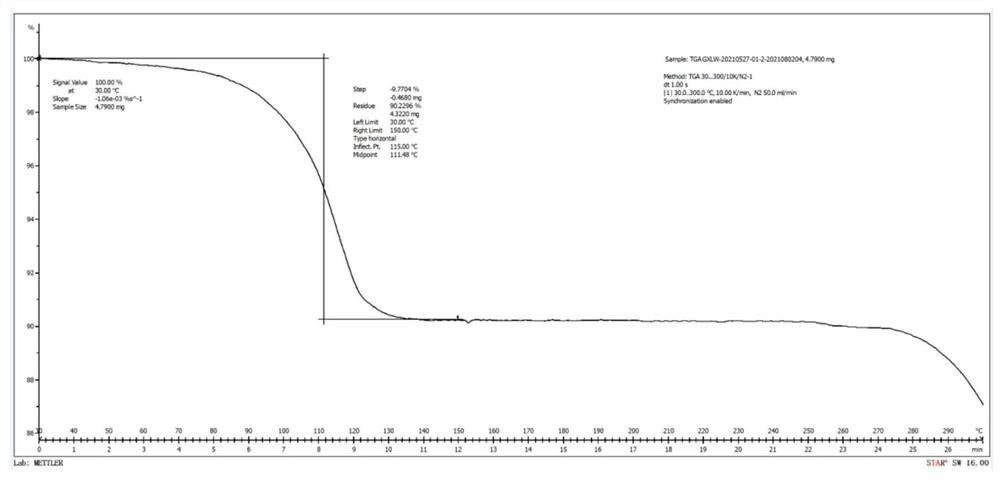

Ganciclovir sodium monohydrate and preparation method thereof

A technology of ganciclovir sodium and monohydrate, which is applied in the field of ganciclovir sodium monohydrate and its preparation, can solve the problem that the moisture absorption capacity of ganciclovir sodium monohydrate is weakened, the product quality is affected, and the product quality is affected. Reduce the content of ingredients and other problems, to achieve the effects of low production cost, easy control, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 20.0g of ganciclovir to 33mL of purified water, stir at room temperature, dissolve 3.2g of sodium hydroxide in 15mL of purified water and add to the system, stir for 3 hours, then add 120mL of 95% ethanol, grow crystals at room temperature for 1h, then filter, and then Add 120mL of 95% ethanol to the crude wet product, heat up to 78°C and stir for 2 hours, filter while hot, then add 200mL absolute ethanol to the crude wet product, heat up to 78°C and stir for 2 hours, filter while hot, vacuum dry to control the internal temperature ≤60°C, vacuum degree ≤0.08Mpa, dry under reduced pressure. 17.5 g of ganciclovir sodium monohydrate was obtained.

Embodiment 2

[0027] Add 20.0g of ganciclovir into 25mL of purified water, stir at room temperature, dissolve 3.2g of sodium hydroxide in 15mL of purified water and add to the system, stir for 2 hours, then add 100mL of 95% ethanol, grow crystals at room temperature for 0.5h, then filter, and then Add 100mL of 95% ethanol to the crude wet product, raise the temperature to 75°C and stir for 1.5 hours, filter while hot, then add 150mL absolute ethanol to the crude wet product, raise the temperature to 75°C and stir for 1.5 hours, filter while hot, and vacuum-dry Dry under reduced pressure at temperature ≤60°C and vacuum degree ≤0.08Mpa.

Embodiment 3

[0029] Add 20.0g of ganciclovir into 40mL of purified water, stir at room temperature, dissolve 3.2g of sodium hydroxide in 20mL of purified water and add to the system, stir for 4 hours, then add 140mL of 95% ethanol, grow crystals at room temperature for 1.5h, then filter, and then Add 140mL of 95% ethanol to the crude wet product, raise the temperature to 80°C and stir for 2.5 hours, filter while hot, then add 250mL absolute ethanol to the crude wet product, raise the temperature to 80°C and stir for 2.5 hours, filter while hot, and vacuum-dry Dry under reduced pressure at temperature ≤60°C and vacuum degree ≤0.08Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com