High-ductility protective film and manufacturing process thereof

A manufacturing process and ductility technology, which is applied in the field of high ductility protective film and its manufacturing process, can solve the problems of reducing the service life of the mold, scratches and cracks on the surface of stamping products, and achieves improved puncture resistance, not easy to break, and expand. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

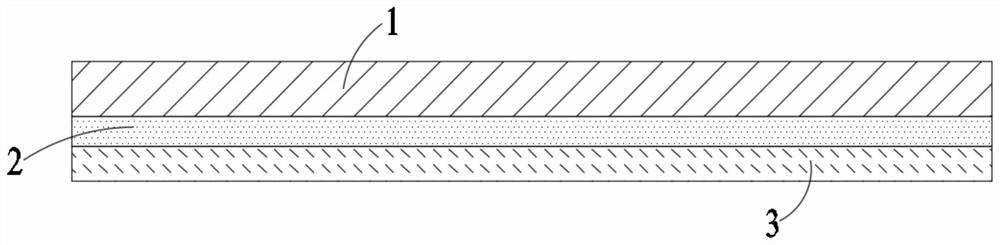

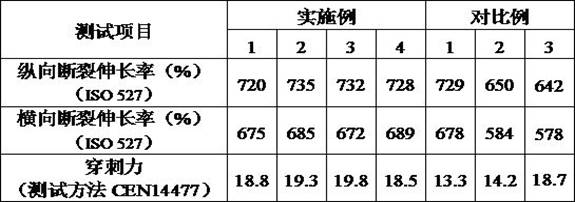

[0037] Embodiments 1 to 4: A high-extensibility protective film, the protective film includes a polyethylene base material layer 1 and an adhesive layer 2 coated on one surface of the polyethylene base material layer 1, the adhesive layer 2 is combined with the polyethylene base material layer 1 A release material layer 3 is bonded to the opposite surface of the vinyl substrate layer 1;

[0038] The polyethylene substrate layer 1 is obtained by blow molding of a master batch to obtain a protective film, and the master batch is composed of the following components by weight, as described in Table 1:

[0039] Table 1

[0040]

Embodiment 1

[0041] In Example 1, the stearate is aluminum stearate, the antioxidant is antioxidant 616, and the terpolymerized polypropylene is ethylene-propylene-1-butene terpolymer.

Embodiment 2

[0042] In Example 2, the stearate is zinc stearate, the antioxidant is antioxidant 1010, and the terpolymerized polypropylene is ethylene-propylene-1-butene terpolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com