A method for improving the tolerance of Corynebacterium glutamicum to inhibitors

A Corynebacterium glutamicum, inhibitor technology, applied in the field of bioengineering, can solve problems such as bacterial growth stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

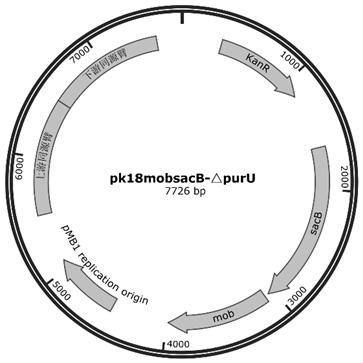

[0035] Example 1 knockout purU Construction of Gene Recombinant Corynebacterium glutamicum

[0036] (1) with C.glutamicum The genomic DNA of ATCC13032 was used as a template, and was designed to knock out according to the sequence of SEQ ID NO.3 purU The left and right homology arms of the gene (about 1kb each) and their primer sequences were amplified by PCR respectively, the products were purified and recovered, and then combined with the digested pK18 mobsacB The plasmid fragment is connected by three-fragment homologous recombination, and the ligation product is introduced by chemical transformation E. coli DH5α competent cells were plated on LB solid plates supplemented with Kan resistance, and cultured overnight in a 37°C incubator. After the single clone grows, pick the single clone and inoculate it into the LB liquid medium supplemented with Kan resistance, extract the recombinant plasmid from the bacterial solution, and obtain the recombinant plasmid pK18 aft...

Embodiment 2

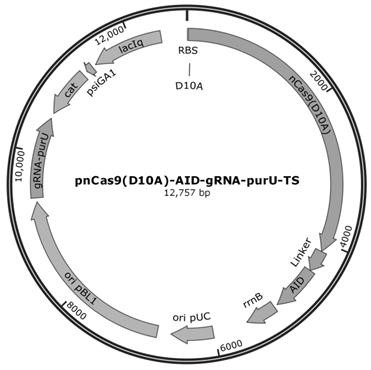

[0038] Example 2 Inactivation purU Construction of Gene Recombinant Corynebacterium glutamicum

[0039] (1) According to SEQ ID NO.3 sequence design for inactivation purU The sgRNA target sequence of the gene (20 bp), according to the target sequence to synthesize two corresponding primers for the sense strand and antisense strand (24 bp each), the primers contain a gap sequence (4 bp) introduced at the 5' end that is paired with the vector . The two primers are annealed to form double-stranded DNA, which is then combined with pnCas9(D10A)-AID-gRNA- ccdB TS The vector plasmid was ligated with Golden Gate and transformed E. coli DH5α competent cells were spread on LB solid plates supplemented with Cm resistance, and cultured overnight in a 37°C incubator. After the single clone grows, pick the single clone and inoculate it into the LB liquid medium supplemented with Cm resistance, extract the recombinant plasmid from the bacterial solution, and obtain the recombinant p...

Embodiment 3

[0041] Example 3 contains serA Construction of recombinant Corynebacterium glutamicum with mutant gene

[0042] 1. By suicide-based plasmid pK18 mobsacB The method of double exchange is constructed, and the steps are as follows:

[0043] (1) with C.glutamicum The genomic DNA of ATCC13032 was used as a template, and was designed for mutation according to the sequence of SEQ ID NO. 4 serA The left and right homology arms of the gene (about 1kb each) and their primer sequences, the mutation site (Q184K) sequence was introduced into the primers, and the left and right homology arms were PCR amplified respectively. pK18 mobsacB The plasmid fragment is connected by three-fragment homologous recombination, and the ligation product is introduced by chemical transformation E. coli DH5α competent cells were plated on LB solid plates supplemented with Kan resistance, and cultured overnight in a 37°C incubator. After the single clone grows, pick the single clone and inoculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com