Thermal component for solid oxide fuel cell system and preparation method thereof

A fuel cell system, solid oxide technology, applied in solid electrolyte fuel cells, fuel cell heat exchange, fuel cells, etc., can solve the problems of increasing system cost, large space, incomplete industrial chain, etc., to increase heat conduction efficiency , the effect of improving efficiency and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

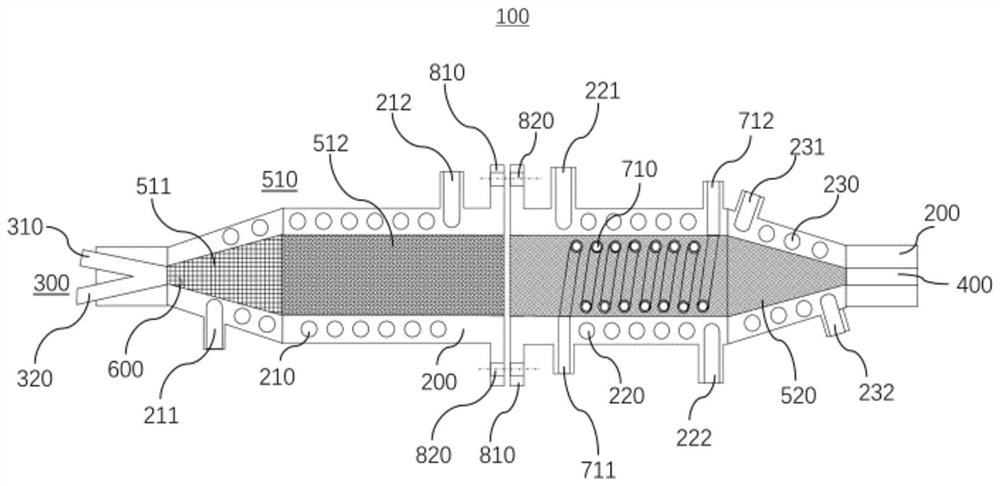

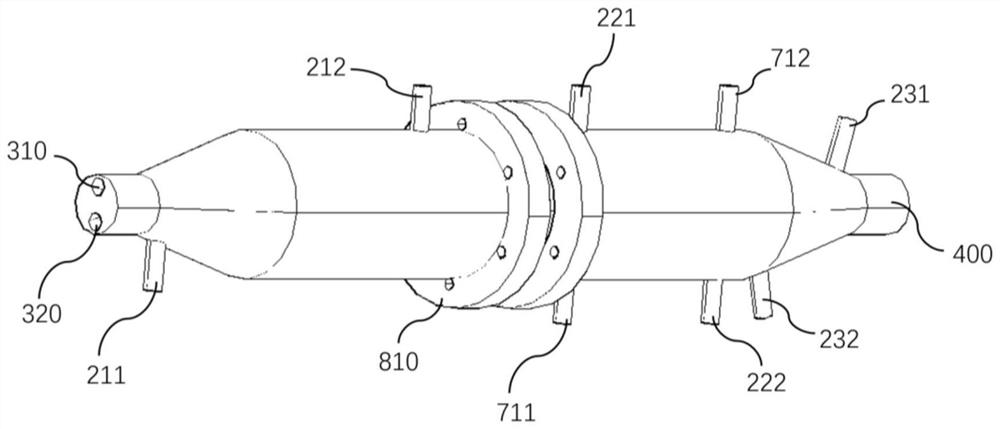

[0070] Please refer to figure 1 , this embodiment provides a thermal component 100 for a solid oxide fuel cell system, including a casing 200 . In this embodiment, the housing 200 has a cylindrical shape in the middle and a tapered airbag-like structure at both ends. In other embodiments, the housing 200 can also be cylindrical, cuboid, conical and so on. Housing 200 is made of metal, specifically Inconel 625.

[0071] An air inlet 300 and an air outlet 400 are provided at opposite ends of the housing 200 respectively. In this embodiment, the air inlet 300 is arranged at the far left of the thermal component 100 , and the air outlet 400 is arranged at the far right of the thermal component 100 . The air inlet 300 includes a first air inlet 310 and a second air inlet 320, and the two air inlets communicate with the cavity in a "V" shape. The confluence of the two inlets in a "V" shape can mix the two inlets in advance to make the gas mix more uniform.

[0072] In this embodi...

no. 2 example

[0093] This embodiment provides a thermal component 100 for a solid oxide fuel cell system. The structure of this component is the same as that of the first embodiment. The only difference is that the preparation method is different. The specific preparation method is as follows:

[0094] drawn by computer Figure 4 As shown in the thermal component 100, the combustion reaction zone 512 of the thermal component 100 is not filled with porous materials. The model is converted into slices to obtain two-dimensional slice path data with a layer thickness of 100 μm, and the above path is imported into the selected area laser sintering 3D printing In the equipment, put Inconel 718 stainless steel raw powder into the printing chamber of the 3D printing equipment, set the printing power to 100W, the scanning interval to 200μm, the scanning speed to 2000mm / s, and the layer thickness to 0.1mm. Close the printing room and perform automatic printing. After printing, heat treatment at 750°C...

no. 3 example

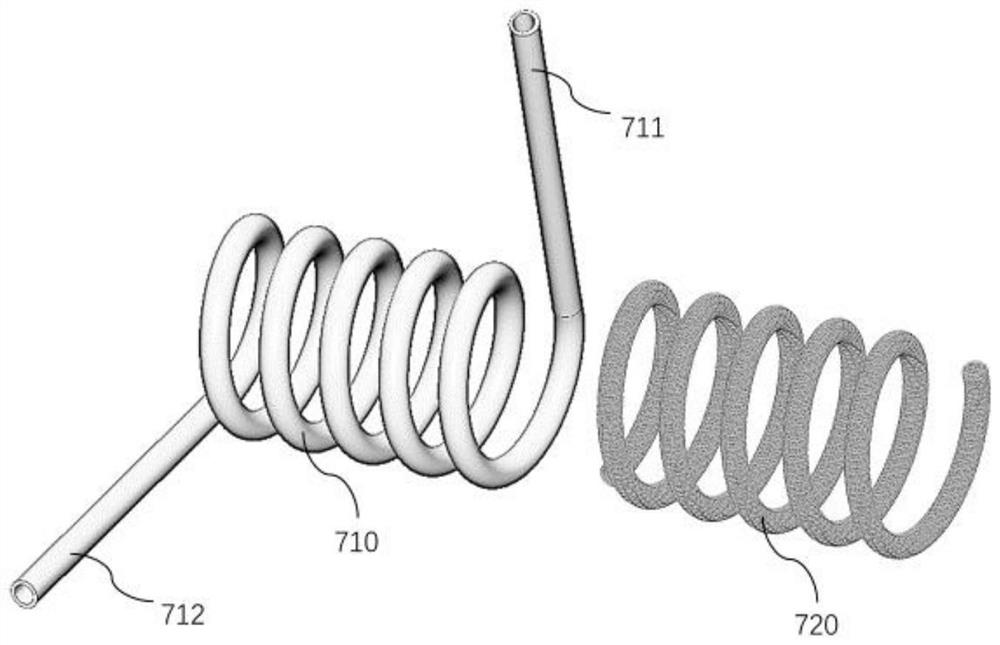

[0096] This embodiment provides a thermal component 100 for a solid oxide fuel cell system. The structure of this component is substantially the same as that of the first embodiment, except that the structure of the reforming channel 710 is different from that of the first embodiment.

[0097] The structure of the reforming channel 710 in this embodiment can be found in Image 6 As shown, the reforming channel 710 of this embodiment is in the shape of a gradually changing spiral tube, and the position of the reforming channel 710 is still in the second heat exchange area 520 .

[0098] The preparation method of a thermal component 100 for a solid oxide fuel cell system provided in this embodiment is as follows:

[0099] drawn by computer figure 1 As shown in the thermal component 100, the structure of the reforming channel 710 is as Image 6 As shown, the model is converted into slices to obtain two-dimensional slice path data with a layer thickness of 100 μm, and the above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com