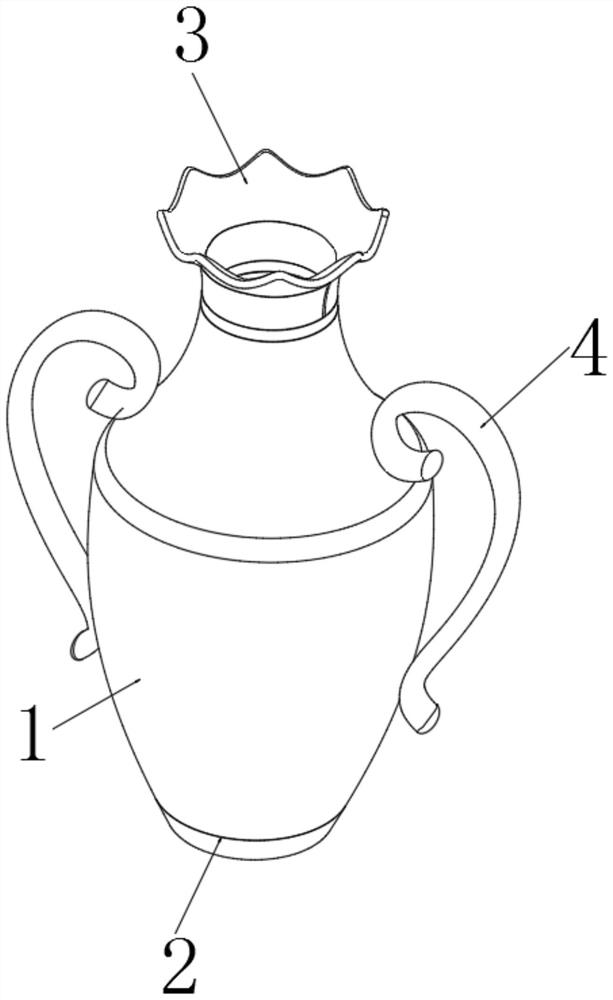

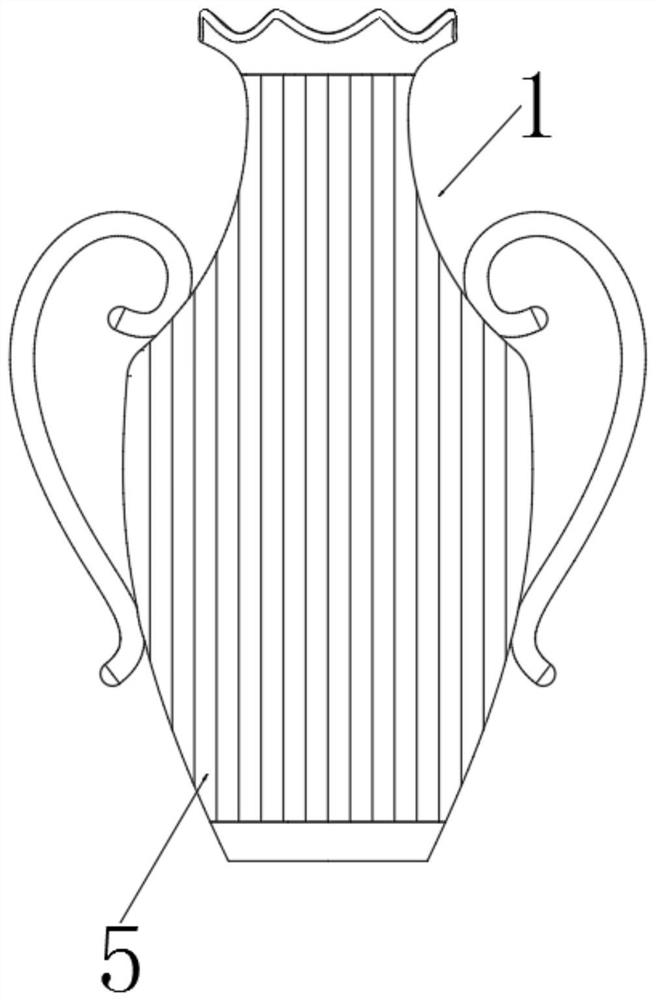

Bamboo vase and production method thereof

A production method and technology for vases, which are applied to vases and other directions, can solve the problems of increased production costs and more waste, and achieve the effects of short processing time, less plate waste, and saving material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] As a kind of embodiment of the present invention, the concrete steps of fresh bamboo processing method are as follows:

[0030] Degreen the whole bamboo, roll it to obtain filamentous raw materials, dry the raw materials until the moisture content is 2%-5%, and the drying temperature is 60-75°C, and then carbonize the raw materials to remove defective products , Put the qualified raw materials after carbonization into the dipping tank for dipping treatment. After the dipping is completed, take out the raw materials and put them on the drain rack for draining treatment until the moisture content of the raw materials is 15- 18%, put the raw material after leaching into a dryer with a temperature of 60-75°C for drying, and dry it until the moisture content of the raw material is 5-10%, then put the dried raw material into the Indoor health care and balance treatment, take out the treated bamboo slices in the health care room, process them through a hot press, and heat pres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap