Germ rice milling method with high germ remaining rate

A high germ retention rate and germ rice technology, which is applied in the field of food processing, can solve the problems of germ rice nutrient loss, high heat on the surface of mechanical grinding discs, and reduced germ retention rate, so as to increase the rice milling time and reduce the damaged area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

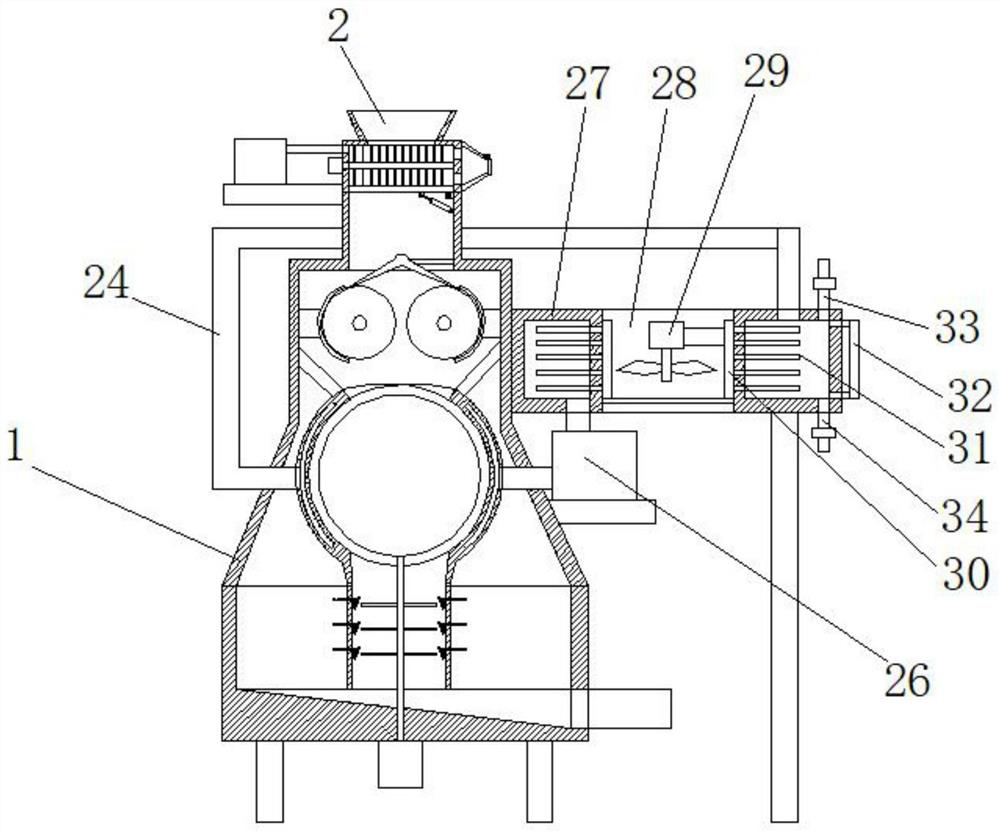

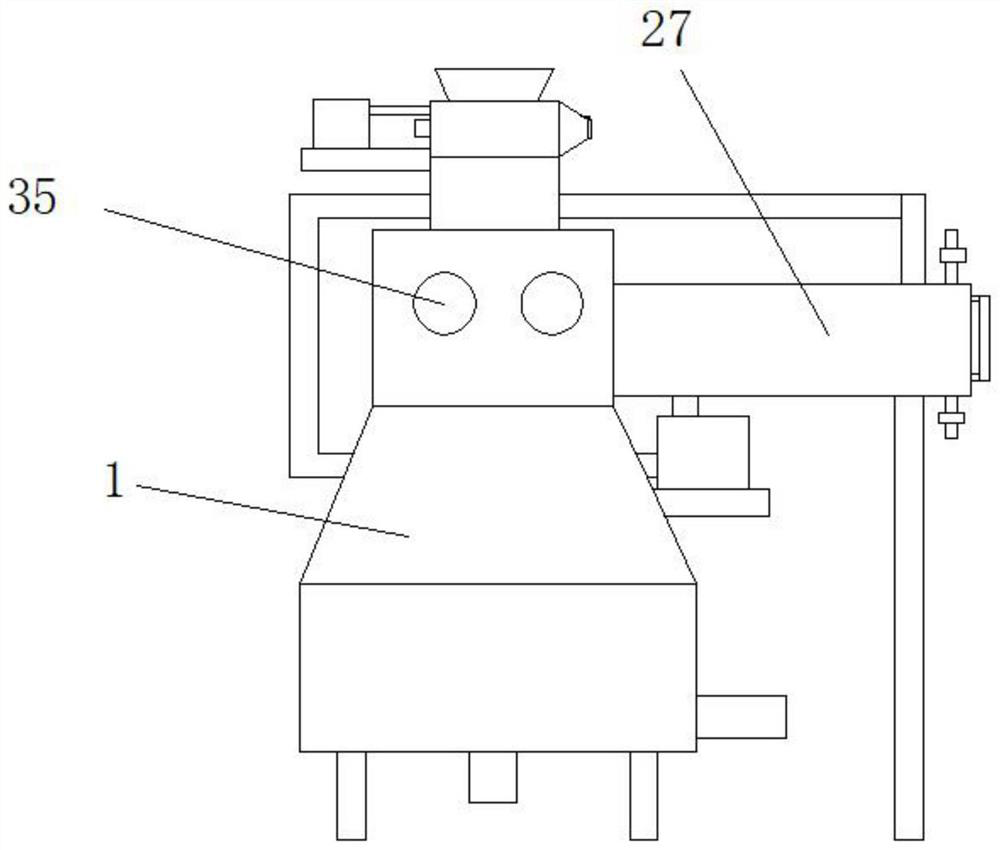

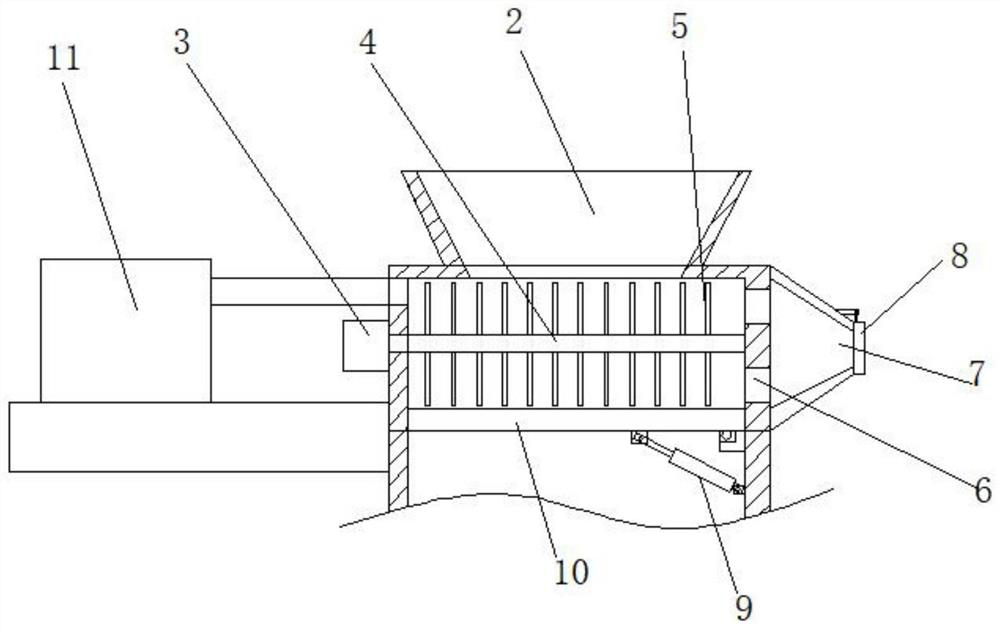

[0023] See Figure 1-6 , the present invention provides a technical solution: a high embryo retention rate of germ rice milling method, comprising the following steps:

[0024] S1, the use of embryo mill to mill rice, first of all, the rice to be milled from the inlet into the inlet, the first motor drives the first shaft rotation, the first shaft drives the rod to turn the meter upwards, open the movable door, the inlet is sealed through the sealing cover, the blower blows the impurities in the rice from the impurity discharge hole to the cone cover, and discharges outward through the opening on the side of the tapered cover, and after 5 minutes, the blower blows the blower speed of 8m / s;

[0025] S2, through the electric pusher to open the partition, the rice falls into the guide plate and rolls down to the gap between the grinding wheel and the curved cover, the third motor drives the grinding wheel to rotate, so that the rice bran layer on the surface of the rice is peeled off...

Embodiment 2

[0030] A high germ rice milling method with high embryo retention rate, including the following steps:

[0031] S1, the use of embryo mill to mill rice, first of all, the rice to be milled from the inlet into the input port, the first motor to drive the first shaft rotation, the first shaft to drive the rod to turn the rice upwards, open the movable door, the inlet through the sealing cover seal, by the blower blower to discharge the impurities in the rice from the impurity discharge hole to the tapered cover, and through the tapered cover side of the opening to discharge outward, 12 minutes after closing the blower, the blower blowing speed of 13m / s;

[0032] S2, through the electric pusher to open the partition, the rice falls into the guide plate and rolls down to the gap between the grinding wheel and the curved cover, driven by the third motor grinding wheel rotation, so that the rice bran layer on the surface of the rice is peeled off, the grinding wheel rotation speed of 20...

Embodiment 3

[0036] A high germ rice milling method with high embryo retention rate, including the following steps:

[0037] S1, the use of embryo mill to mill rice, first of all, the rice to be milled from the inlet into the inlet, the first motor drives the first shaft rotation, the first shaft drives the rod to turn the meter upwards, open the movable door, the inlet is sealed through the sealing cover, the air blower blows the impurities in the rice from the impurity discharge hole to the tapered cover, and discharges outward through the opening on the side of the tapered cover, and after 5-12 minutes, the blower blows the blower speed of 9m / s;

[0038] S2, through the electric pusher to open the partition, the rice falls into the guide plate and rolls down to the gap between the grinding wheel and the arc cover, the third motor drives the grinding wheel to rotate, so that the rice bran layer on the surface of the rice is peeled off, and the grinding wheel rotation speed is 69 rpm / s;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com