Degradable preservative film special for edible mushrooms and preparation method

A technology of plastic wrap and edible fungus, which is applied in the field of degradable plastic wrap for edible fungus and its preparation, which can solve the problems of lack of plastic wrap and achieve the effects of improving hydrophobicity, weakening nano-action energy, improving dispersion and compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the above-mentioned special degradable plastic wrap for edible fungus, the steps are as follows:

[0049] (1) Preparation of PLA / PBAT / PCL / PVA quaternary blend degradable cling film base material: First, use dimethyl sulfoxide (DMSO) as solvent, add PVA (polyvinyl alcohol) to prepare a mass fraction of 5%- 10% solution, then keep the water bath at 120-145°C, add film-forming substrates PLA (polylactic acid), PBAT (polyadipic acid / butylene terephthalate) with a total mass of 8%-10% of the solution in the water bath in sequence Ester), PCL (polycaprolactone), PLA:PBAT:PCL mass ratio is 30~40:60~70:2~5, stir evenly, after completely dissolved, cool down, then vacuum dry at 80℃ to constant weight , and pulverized to obtain a quaternary blend degradable plastic wrap substrate;

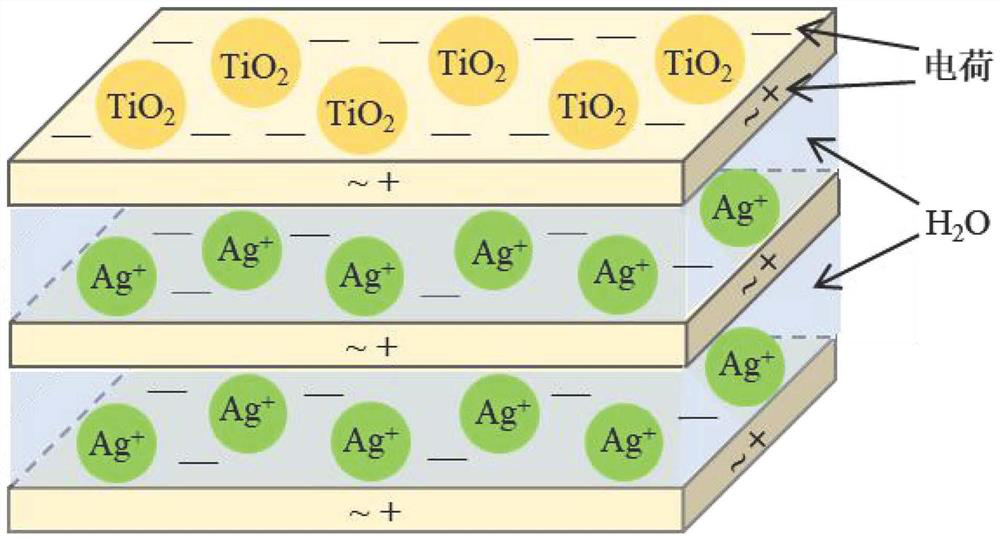

[0050] (2) Preparation of slow-release nano-intercalation antibacterial additives: first, nano-TiO 2 Carry out physical ultrasonic synergistic chemical coupling modificatio...

Embodiment 1

[0074] A special degradable plastic wrap for edible fungus, comprising the following raw materials in parts by weight: 100 parts of PLA / PBAT / PCL / PVA quaternary blended degradable plastic wrap substrate, 2 parts of slow-release nano-intercalated antibacterial additives, breathable and anti-fog 2 parts of additives, 1 part of degradation accelerator.

[0075] The preparation method of the special degradable plastic wrap for edible fungi is as follows:

[0076] First, wet the quaternary blended degradable plastic wrap base material with a certain amount of acetone solvent, then add antibacterial additives, breathable anti-fog additives and degradation accelerators in proportion, first stir at 70rpm at low speed for 2min, then at 150rpm at high speed Stir for 3 minutes to obtain a mixed material in which the additives are evenly adsorbed on the substrate; after that, the twin-screw extruder melts and blends and repeats the granulation twice to improve the uniformity of the masterb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com