Mn-PtM/C type platinum-based oxygen reduction catalyst as well as preparation method and application thereof

A catalyst, mn-ptm technology, applied in the field of electrochemistry, can solve the problems of reducing the load of platinum nanoparticles or platinum alloy nanoparticles, low ORR performance, etc., and achieve the effect of low cost, high catalytic activity and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

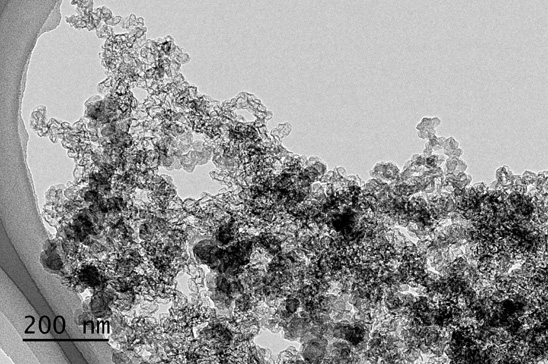

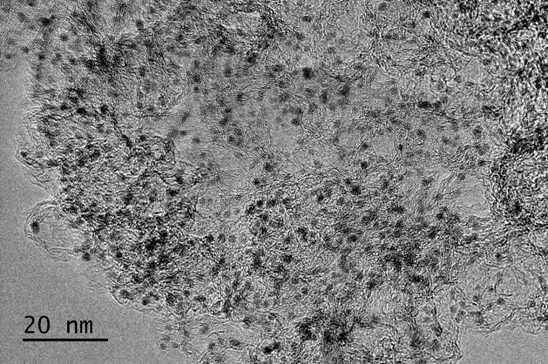

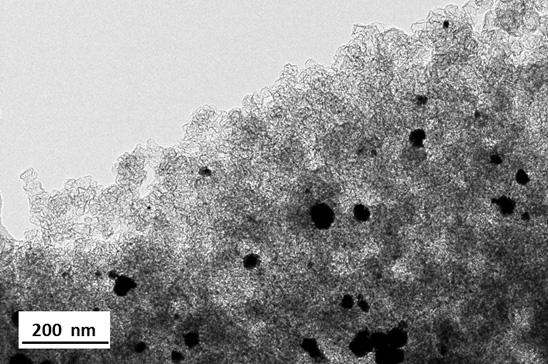

Image

Examples

Embodiment 1

[0056] This embodiment provides a method for preparing a Mn-PtM / C-type platinum-based oxygen reduction catalyst, the preparation method comprising the following steps:

[0057] (1) Weigh 100 mg of Ketjen Black after the above pretreatment, add 2.8 mL of MnCl with a concentration of 0.01 mol / L 2 Ethylene glycol solution, mix with 50mL ethylene glycol ultrasonically for 1h, then add 8.5mL ethylene glycol solution of chloroplatinic acid hexahydrate with a concentration of 0.01mol / L, use ethylene glycol solution of KOH with a concentration of 1mol / L Adjust the pH to 10 to obtain a mixed reaction solution;

[0058] (2) Put the mixed reaction solution obtained in step (1) on an oil bath, and heat to reflux at 150°C for 3 hours under a nitrogen atmosphere to obtain a reaction mixture;

[0059] (3) Cool the reaction mixture obtained in step (2) to room temperature, centrifuge at 8000rpm for 5min, then wash the obtained solid with distilled water several times until the washing liquid...

Embodiment 2

[0061] This example provides a preparation method of Mn-PtM / C platinum-based oxygen reduction catalyst, based on the preparation method described in Example 1, the only difference is: in step (1), add 8.2mL concentration of 0.01mol / LMnCl 2 Ethylene glycol solution.

Embodiment 3

[0063] This example provides a preparation method of a Mn-PtM / C platinum-based oxygen reduction catalyst, based on the preparation method described in Example 1, the only difference is that in step (1), 1.4mL is added at a concentration of 0.01mol / LMnCl 2 Ethylene glycol solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com