Quick-frozen beef granule product with high oxidation resistance and strong antibacterial ability and preparation method of quick-frozen beef granule product

A technology of beef grains and oxidative properties, which is applied in the field of quick-frozen beef grains with strong antibacterial ability and its preparation, and high anti-oxidation, can solve the problems of microbial multi-phase pollution, and achieve the improvement of anti-oxidation activity, high anti-oxidation, The effect of prolonging the shelf life of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cleaning and trimming: Rinse the selected fresh beef with clean water for 2 minutes, use a skinning machine to remove the fascia on the surface of the beef, cut off the broken bones and large pieces of oil in the beef, and then cut the beef into chunks of about 1kg ;

[0036] Soaking: Mix 4.00kg of drinking water, 0.30kg of white vinegar, 0.25kg of white wine, 0.10kg of lemon juice and 0.20kg of honey to make a soaking liquid, put it into the cleaned beef, soak for 30 minutes, remove blood and water impurities, and drain;

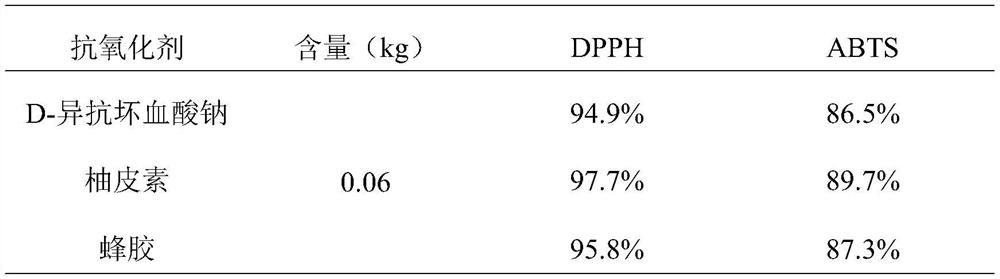

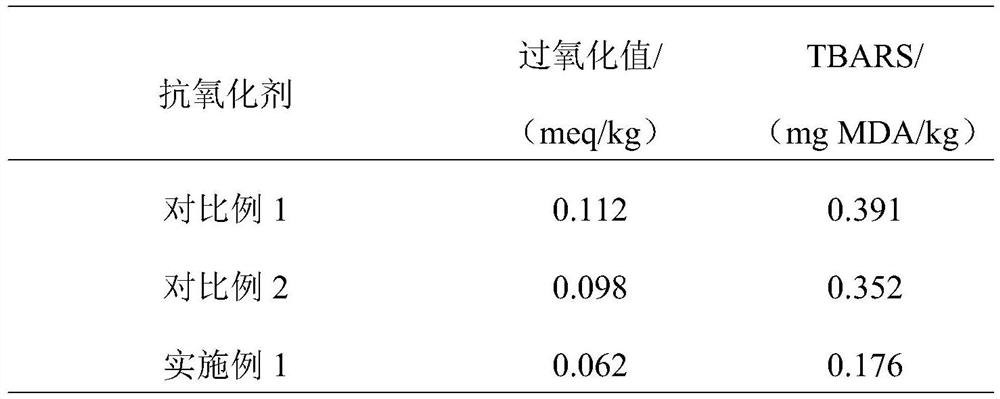

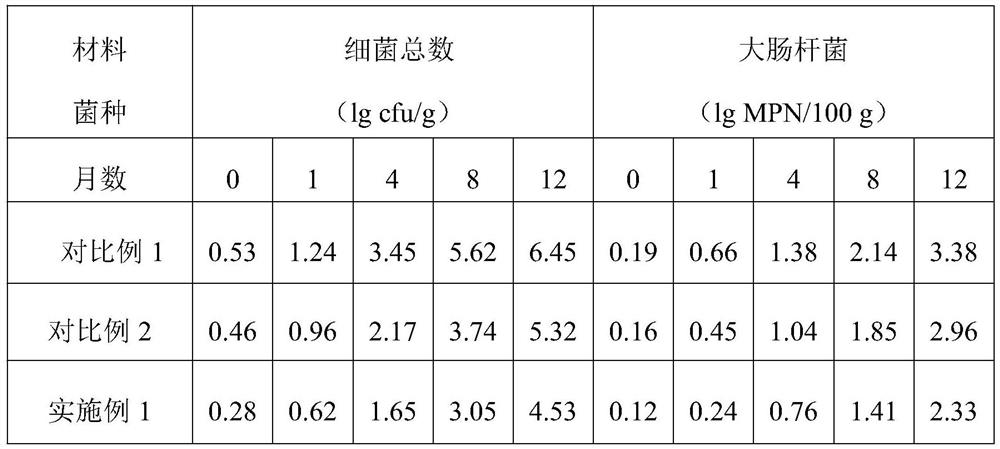

[0037] Pickling: 1.50kg of drinking water, 0.15kg of raw powder, 0.22kg of edible salt, 0.15kg of white sugar, 0.20kg of compound phosphate (sodium pyrophosphate, sodium tripolyphosphate, sodium hexametaphosphate), 0.12kg of monosodium glutamate, 0.05 kg naringenin, 0.15 kg bovine lactoferrin, 0.06 kg propolis and other materials were mixed and stirred evenly to make a marinade liquid. Using the injection method, the marinade liquid was divided into ...

Embodiment 2

[0063] Cleaning and trimming: Rinse the selected fresh beef with clean water for 2 minutes, use a skinning machine to remove the fascia on the surface of the beef, cut off the broken bones and large pieces of oil in the beef, and then cut the beef into chunks of about 1kg ;

[0064] Soaking: Mix 4.50kg of drinking water, 0.45kg of white vinegar, 0.35kg of white wine, 0.20kg of lemon juice and 0.30kg of honey to make a soaking liquid, put it into the cleaned beef, soak for 40 minutes, remove blood and water impurities, and drain;

[0065] Pickling: 1.60kg of drinking water, 0.20kg of raw powder, 0.20kg of edible salt, 0.18kg of white sugar, 0.08kg of compound phosphate, 0.15kg of monosodium glutamate, 0.08kg of naringenin, 0.20kg of bovine lactoferrin and 0.05kg of propolis, etc. Mix and stir the ingredients evenly to make a marinade liquid, divide the marinade liquid into three parts and inject it into the beef from three directions, and marinate the beef in the marinade liqui...

Embodiment 3

[0088] Cleaning and trimming: Rinse the selected fresh beef with clean water for 2 minutes, use a skinning machine to remove the fascia on the surface of the beef, cut off the broken bones and large pieces of oil in the beef, and then cut the beef into chunks of about 1kg ;

[0089] Soaking: Mix 4.20kg of drinking water, 0.34kg of white vinegar, 0.28kg of white wine, 0.12kg of lemon juice, and 0.25kg of honey to make a soaking liquid, put it into the cleaned beef, soak for 30 minutes, remove blood and water impurities, and drain;

[0090]Pickling: 1.80kg of drinking water, 0.18kg of raw powder, 0.27kg of edible salt, 0.18kg of white sugar, 0.30kg of compound phosphate, 0.14kg of monosodium glutamate, 0.05kg of naringenin, 0.17kg of bovine lactoferrin and 0.10kg of propolis, etc. The ingredients are mixed and stirred evenly to make a marinade liquid, and the marinade liquid is divided into three parts and injected into the beef from three directions by injection method, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Escherichia coli | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com