Preservative and fresh-keeping method of soy sauce

A fresh-keeping method and technology of soy sauce, applied in food preservation, food science, application, etc., to achieve the effect of rapid enzymatic hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

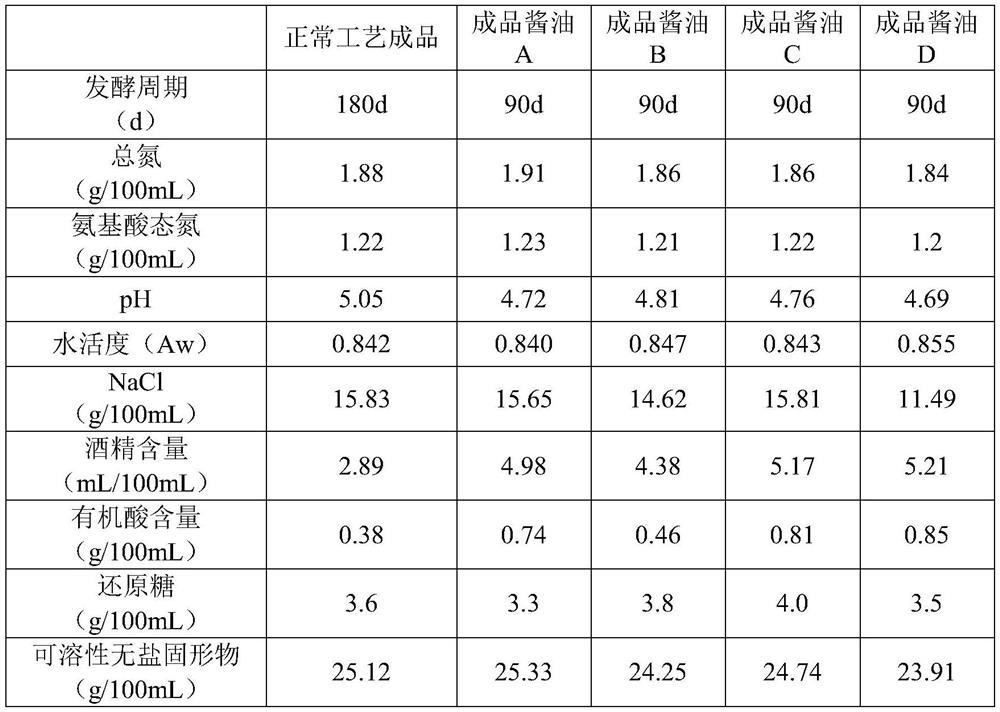

[0056] Embodiment 1: High temperature continuous fermentation is adopted in the early stage of fermentation

[0057] According to the detailed method steps 1) to 3) to prepare the finished koji, mix it with salt water according to the weight ratio of 1:2.5, adjust the salt content of the soy sauce to 16g / 100g, carry out high-temperature fermentation at 40°C for 50 days, and add priority 3.6×10 6 CFU / g of lactic acid bacteria, continue to ferment for 20 days at 25-30°C, and then add 5.1×10 6 CFU / g of yeast, 25-30 ° C to continue fermentation at room temperature for 20 days, the total fermentation time is 90 days, during the 30th day and the 60th day of the drum tank, the soy sauce juice obtained by pressing after the fermentation is completed, after deployment, sterilization Bacteria, filtration, and filling to obtain finished soy sauce A.

[0058] The finished soy sauce A and the normal process finished soy sauce were inoculated with 10 2 CFU / g, 10 3 CFU / g, 10 4 CFU / g of ...

Embodiment 2

[0059] Embodiment 2: only add yeast

[0060] According to the detailed method steps 1) to 3) to prepare the koji, mix it with salt water according to the weight ratio of 1:2.4, adjust the salt content of the soy sauce to 15g / 100g, and carry out high-temperature fermentation at 40°C for 40 days. Vinegar to adjust the pH of the moromi to below 5.0, add 4.8×10 6 CFU / g of yeast, continue to ferment for 50 days, the fermentation temperature is 25-30 ° C, the total fermentation time is 90 days, drum pooling is carried out during the process of adding strains, and the soy sauce juice obtained by squeezing after fermentation is blended, sterilized Bacteria, filtration, and filling to obtain finished soy sauce B.

[0061] Finished soy sauce B and normal process finished soy sauce were inoculated with 10 2 CFU / g, 10 3 CFU / g, 10 4 The yeast of CFU / g was subjected to microbial challenge test, and the finished soy sauce B was inoculated with 10 4 CFU / of yeast, part of the bottle bulg...

Embodiment 3

[0062] Embodiment 3: High temperature staged fermentation is adopted in the early stage of fermentation

[0063] The koji prepared according to the detailed method steps 1) to 3) is mixed with salt water according to the weight ratio of 1:2.5, the salt content of the soy sauce is adjusted to 16g / 100g, and the high-temperature fermentation is carried out at 40°C for 20 days, and then at 50°C Continue to ferment at high temperature for 20 days under the same conditions, and then add 3.6×10 6 CFU / g of lactic acid bacteria, continue to ferment for 20 days at 25-30°C, and then add 5.1×10 6 CFU / g of yeast, 25-30 ℃ to continue fermentation for 30 days, the total fermentation time is 90 days, during the 40th and 60th day of the drum tank, the soy sauce juice obtained by pressing after the fermentation is completed, prepared and sterilized , filtering and filling to obtain finished soy sauce C.

[0064] The finished soy sauce C and the normal process finished soy sauce were inoculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com