Implant for preventing anastomotic fistula

An anastomotic leakage and implant technology, which is applied in the field of implants for preventing anastomotic leakage, can solve the problems of increasing cost, cannot reduce anastomotic leakage, etc., so as to increase anti-leakage pressure, prevent early anastomotic leakage, prevent Effects of mid- and late-stage anastomotic leaks and anastomotic strictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] This embodiment provides a disc-shaped implant (with a hole in the middle) with a diameter of 2.9 cm, which is specifically prepared by the following method:

[0076] (1) Dissolving the fibrinogen complex in physiological saline with a concentration of 15g%;

[0077] (2) poly(lactic acid polycaprolactone) copolymer is dissolved in hexafluoroisopropanol solvent with a mass concentration percentage of 8%;

[0078] (3) Mix the solution obtained in step (1) and step (2) and add it into the same capacity tube of the electrospinning machine, so that the mass ratio of the fibrinogen complex to the poly(lactic acid polycaprolactone) copolymer is 0.56: 1. Prepare by electrospinning (electrospinning machine model: NS1WS 500Elmarco Czech Republic); the voltage difference of spinning is 50kv, the spinning distance is 40cm, and the spinning solution propulsion speed is 50ml / h;

[0079] (4) Residual organic solvent in the implant obtained by electrospinning is removed, and then ster...

Embodiment 2

[0082] In this embodiment, the disc-shaped implant with a diameter of 2.9 cm (open hole in the middle), the specific preparation method is the same as that in Embodiment 1.

[0083] This embodiment specifically provides 5 kinds of implants with different porosities; the porosities of the 5 kinds of implants are respectively 10%, 20%, 40%, 80% and 95%, and the corresponding thickness is between 0.2mm-0.38mm. In the range of mm, the water absorption rate is in the range of 50%-100%, and the bursting strength is in the range of 20N-80N.

Embodiment 3

[0085] This embodiment provides a disc-shaped implant with a diameter of 2.9 cm (with a hole in the middle), and the specific preparation method is the same as that in Embodiment 1.

[0086] This embodiment specifically provides 6 kinds of implants with different water absorption rates; the water absorption rates of the 6 kinds of implants are respectively 10%, 20%, 50%, 100%, 200% and 300%, and the corresponding thickness is 0.2 In the range of mm-0.38mm, the porosity is in the range of 40%-80%, and the bursting strength is in the range of 20N-80N.

[0087] performance test 1

[0088] 1. Test method:

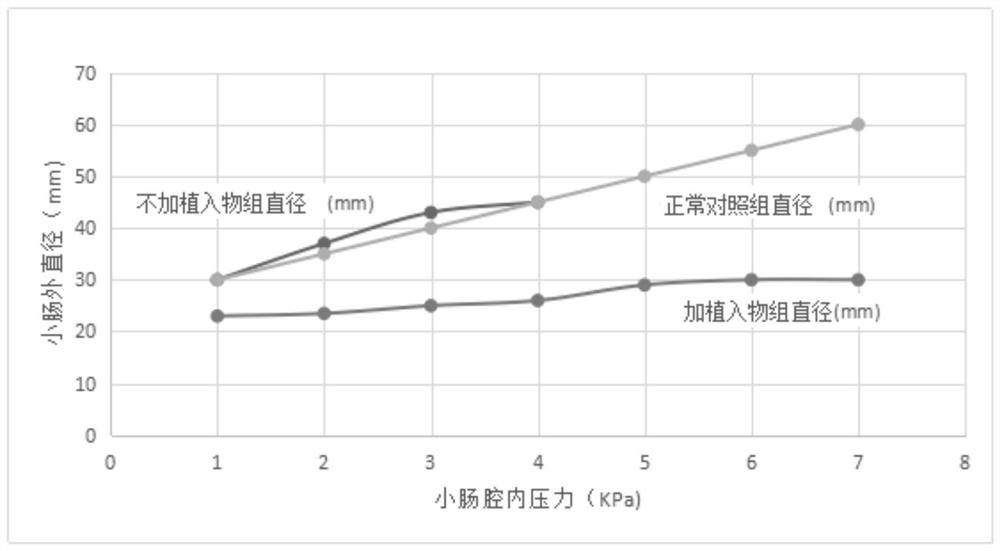

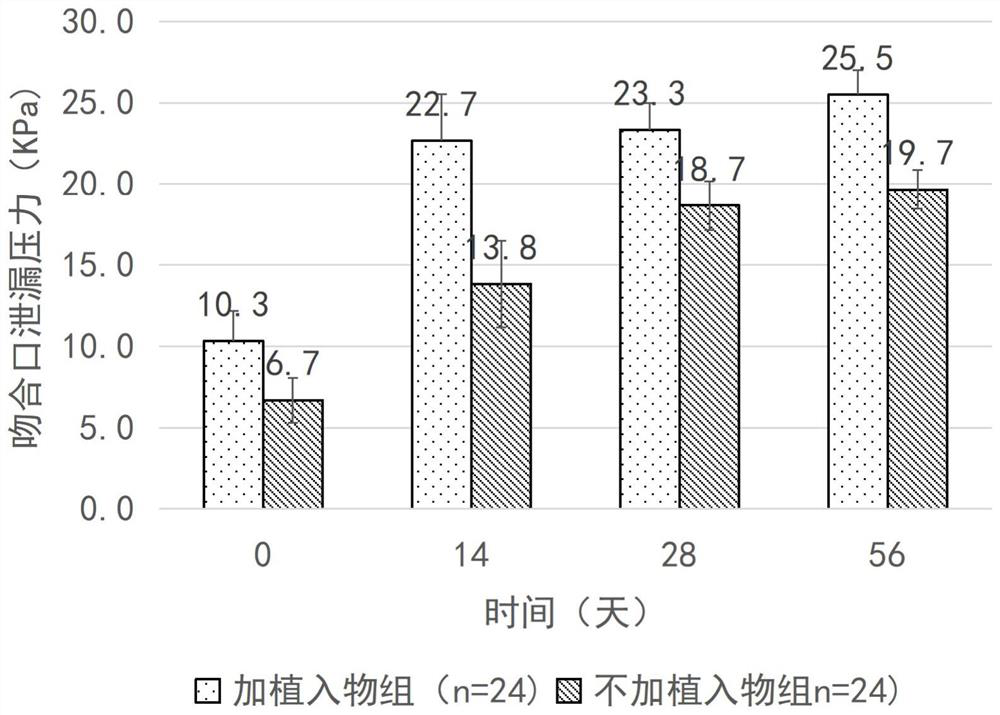

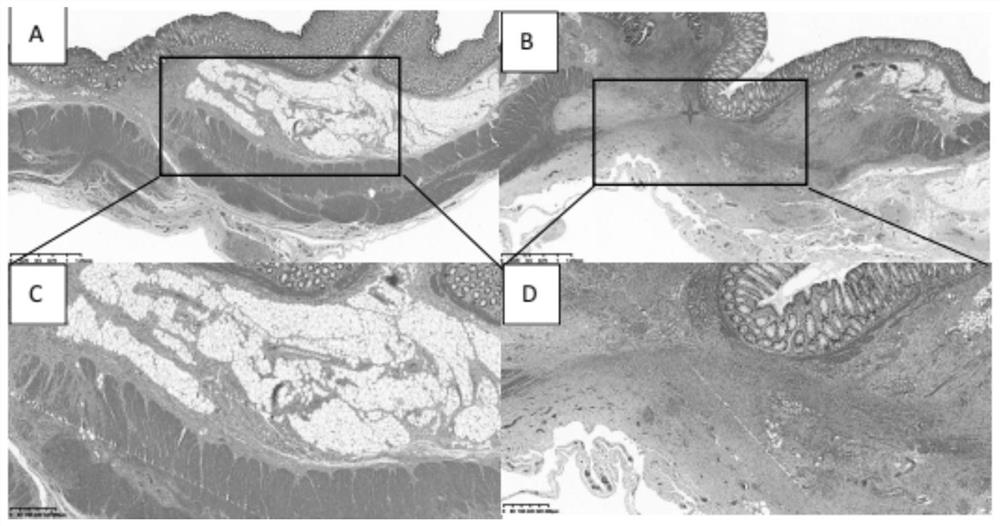

[0089] Take the fresh small intestine of pigs with a weight of 100-150kg, intercept the fresh small intestine with a length of 10cm, and cut each section into two sections of equal length from the middle; use a tubular stapler (CN-CS29, Jiangsu Chennuo Medical Instrument Co., Ltd.) for anastomosis, The implant provided by the embodiment is placed between the distal and proxim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com