Method for splicing and processing sintered neodymium iron boron magnetic balls

A technology of neodymium iron boron and magnetic balls, which is applied in chemical instruments and methods, inductance/transformer/magnet manufacturing, solid separation, etc., can solve the problems of reduced screening efficiency, screen blockage, unfavorable screening, etc., to improve cleaning efficiency, Not easy to clog and reduce temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

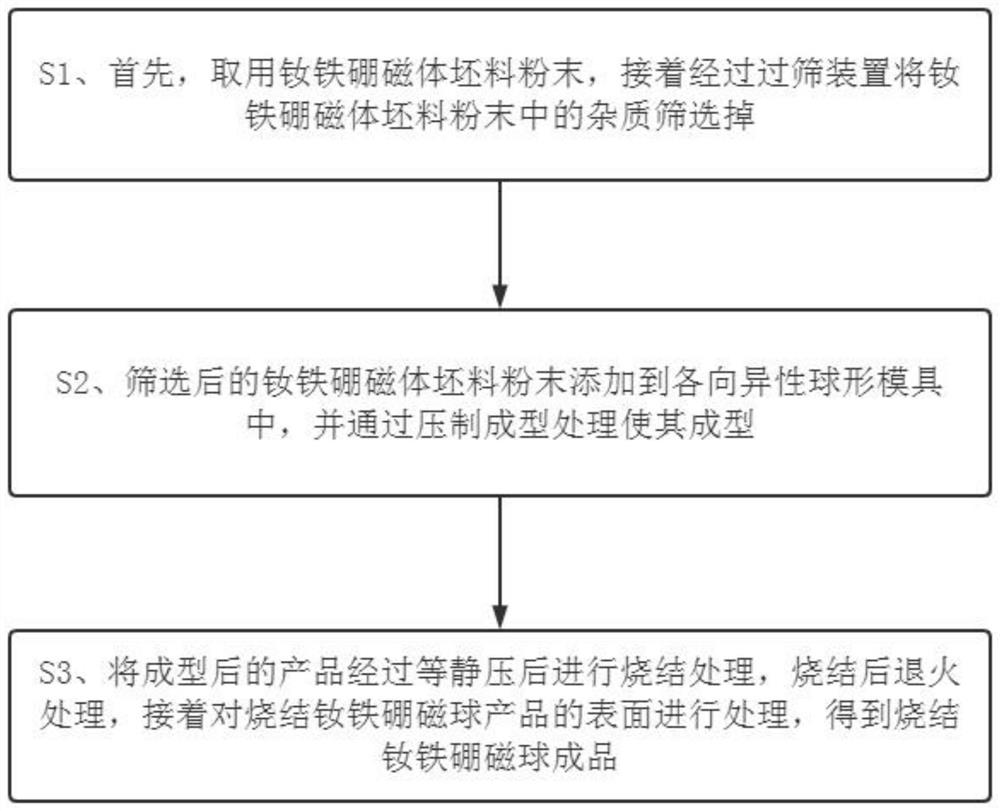

[0044] see figure 1 , a method for splicing and processing sintered NdFeB magnetic balls, comprising the following steps:

[0045] S1. First, take the NdFeB magnet blank powder, and then pass through the sieving device to screen out the impurities in the NdFeB magnet blank powder;

[0046] S2. The screened NdFeB magnet blank powder is added to the anisotropic spherical mold, and it is formed by pressing and forming. Because the sintering shrinkage rate is different in each direction of the spherical shape, if the sintered magnet is spherical, the mold cannot Spherical, otherwise if the mold is spherical, the spherical green body will become an ellipsoid after sintering, so choose a spherical mold with a very close diameter in all directions, that is, an anisotropic spherical mold, to reduce the impact of shrinkage;

[0047] S3. Sintering the formed product after isostatic pressing, annealing after sintering, and then treating the surface of the sintered NdFeB magnetic ball pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com