Improved lime material for repairing building heritage walls and preparation method thereof

A heritage and wall technology, applied in the field of improved lime materials and preparation for the repair of architectural heritage walls, can solve the problems that hydraulic lime cannot meet the requirements of construction technology, the masonry process is complicated, and it takes a lot of time to optimize the slurry. Composition, delaying the hydration process, prolonging the effect of setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

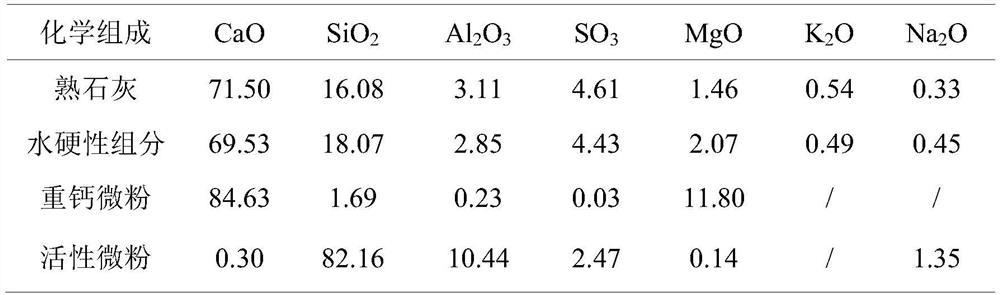

[0034] An improved lime material for building heritage wall repair, the mass percentage of the lime material is as follows:

[0035]

[0036]

[0037] Mix slaked lime, hydraulic components, heavy calcium micropowder and active micropowder evenly in proportion, and then use a ball mill to mill for 5 minutes at a speed of 100rpm to obtain a mixture; put the obtained mixture, cellulose ether and sucrose into a high-speed mixer and mix evenly , the mixing speed is 600rpm, and the optimized lime cementitious material is obtained.

[0038] Refer to the European standard BS EN196-1-2005 for the molding requirements of mortar specimens. The water-binder ratio is selected as 0.55 and the mortar ratio is 1:3. After demoulding, test the flexural strength and compressive strength. At the same time, referring to GBT 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method", the standard consistency water consumption is used to make standard c...

Embodiment 2

[0043] An improved lime material for building heritage wall repair, the mass percentage of the lime material is as follows:

[0044]

[0045] Mix slaked lime, hydraulic components, heavy calcium micropowder and active micropowder evenly in proportion, and then use a ball mill to mill for 8 minutes at a speed of 200rpm to obtain a mixture; put the obtained mixture, cellulose ether and sucrose into a high-speed mixer and mix evenly , the mixing speed is 800rpm, and the optimized lime cementitious material is obtained.

[0046] Refer to the European standard BS EN196-1-2005 for the molding requirements of mortar specimens. The water-binder ratio is selected as 0.55 and the mortar ratio is 1:3. After demoulding, test the flexural strength and compressive strength. At the same time, referring to GBT 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method", the standard consistency water consumption is used to make standard consistency c...

Embodiment 3

[0051] An improved lime material for building heritage wall repair, the mass percentage of the lime material is as follows:

[0052]

[0053] Mix slaked lime, hydraulic components, heavy calcium micropowder and active micropowder evenly in proportion, and then use a ball mill to mill for 10 minutes at a speed of 400rpm to obtain a mixture; put the obtained mixture, cellulose ether and sucrose into a high-speed mixer and mix evenly , the mixing speed is 1000rpm, and the optimized lime cementitious material is obtained.

[0054] Refer to the European standard BS EN196-1-2005 for the molding requirements of mortar specimens. The water-binder ratio is selected as 0.55 and the mortar ratio is 1:3. After demoulding, test the flexural strength and compressive strength. At the same time, referring to GBT 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method", the standard consistency water consumption is used to make standard consistency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com