Environment-friendly blocked mercaptosilane and mercaptosilane copolymer and preparation method thereof

A technology of mercaptosilane and mercaptopropyltriethoxysilane is applied in the field of environment-friendly end-capped mercaptosilane and mercaptosilane copolymer and its preparation, and can solve the problem of failure to achieve green environmental protection, large emission of volatile organic compounds, and glue The problem of early scorch phenomenon of materials can be improved, so as to improve the driving safety of automobiles, save energy, and improve the effect of early scorch phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

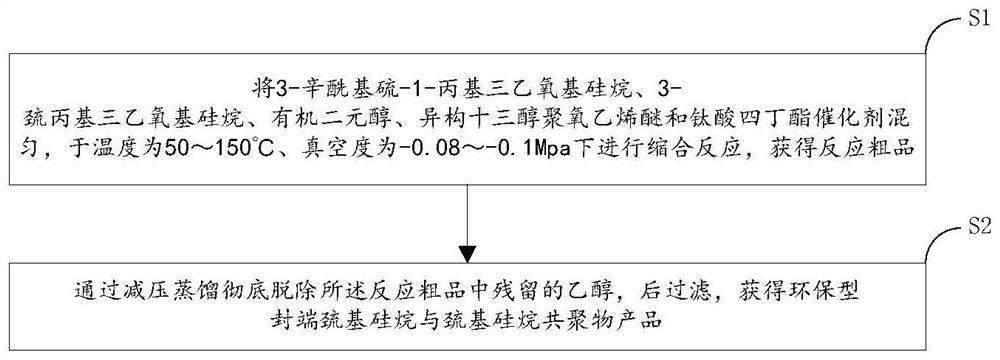

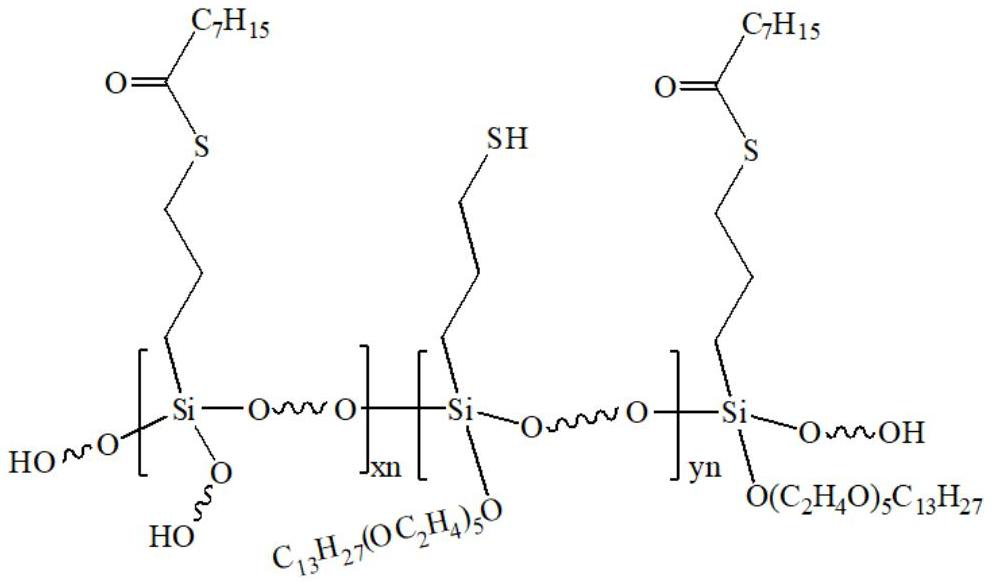

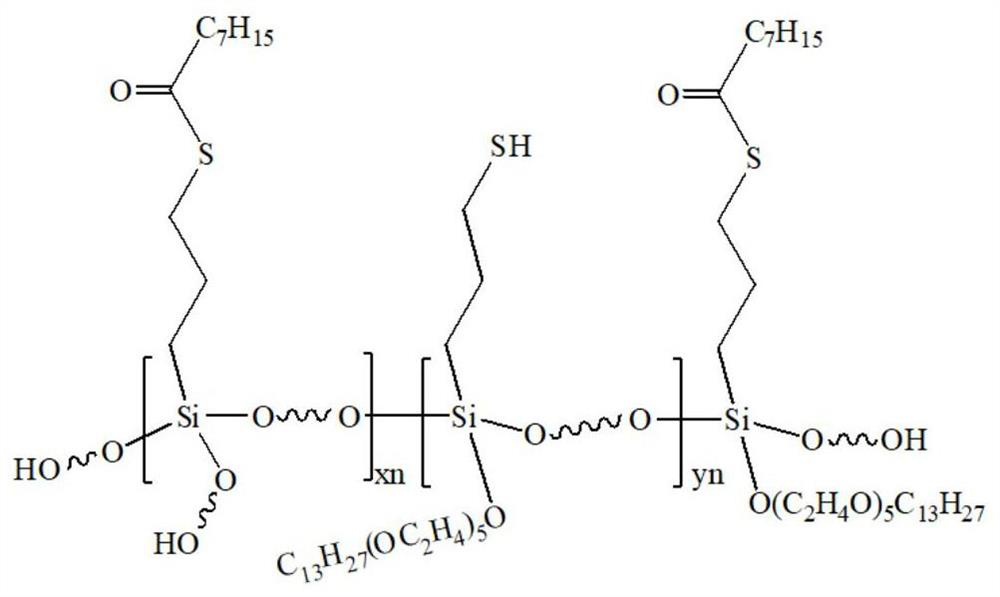

[0035] The preparation method of an environment-friendly blocked mercaptosilane and mercaptosilane copolymer provided by the embodiment of the present invention includes:

[0036] Under a nitrogen atmosphere, drop into 182.3g (0.5mol) of 3-octanoylthio-1-propyltriethoxysilane in a 1000ml four-necked flask equipped with a magnetic stirrer, a condenser, a thermometer and a distillation device, 3 - Mercaptopropyltriethoxysilane 119.2g (0.5mol), 1,3-propanediol 213.1g (2.8mol) and isomeric tridecyl alcohol polyoxyethylene ether 84g (0.2mol), then add tetrabutyl titanate Catalyst 250 μl. Start the magnetic stirring and slowly raise the temperature. When the temperature reaches 100°C, start to pump negative pressure to make the vacuum in the system reach -0.095Mpa. The ethanol produced by the reaction is continuously distilled until there is no ethanol. The entire reaction time is about 5 hours.

[0037] After the reaction, a total of 138.2 g of ethanol was collected, which was con...

Embodiment 2

[0039] The preparation method of an environment-friendly blocked mercaptosilane and mercaptosilane copolymer provided by the embodiment of the present invention includes:

[0040] Under a nitrogen atmosphere, drop into 218.8g (0.6mol) of 3-octanoylthio-1-propyltriethoxysilane in a 1000ml four-necked flask equipped with a magnetic stirrer, a condenser, a thermometer and a distillation device, 3 - Mercaptopropyltriethoxysilane 95.4g (0.4mol), 1,3-propanediol 220.7g (2.9mol) and isomeric tridecyl alcohol polyoxyethylene ether 42g (0.1mol), then add tetrabutyl titanate Catalyst 260 μl. Start the magnetic stirring and slowly raise the temperature. When the temperature reaches 100°C, start to pump negative pressure to make the vacuum in the system reach -0.095Mpa. The ethanol produced by the reaction is continuously distilled until there is no ethanol. The entire reaction time is about 5 hours.

[0041] After the reaction, a total of 138.0 g of ethanol was collected, which was consis...

Embodiment 3

[0043] The preparation method of an environment-friendly blocked mercaptosilane and mercaptosilane copolymer provided by the embodiment of the present invention includes:

[0044] Under a nitrogen atmosphere, drop into 182.3g (0.5mol) of 3-octanoylthio-1-propyltriethoxysilane in a 1000ml four-necked flask equipped with a magnetic stirrer, a condenser, a thermometer and a distillation device, 3 - Mercaptopropyltriethoxysilane 119.2g (0.5mol), 1,3-propanediol 213.1g (2.8mol) and isomeric tridecyl alcohol polyoxyethylene ether 84g (0.2mol), then add tetrabutyl titanate Catalyst 250 μl. Start the magnetic stirring and slowly raise the temperature. When the temperature reaches 120°C, start to pump negative pressure to make the vacuum in the system reach -0.095Mpa. The ethanol produced by the reaction is continuously distilled until there is no ethanol. The entire reaction time is about 5 hours.

[0045] After the reaction, a total of 138.1 g of ethanol was collected, which was con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com