Brewing process of tomato wine

A tomato and tomato juice technology, applied in the preparation of alcoholic beverages, methods based on microorganisms, microorganisms, etc., to achieve the effect of transparent appearance, moist and non-irritating taste, and natural ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

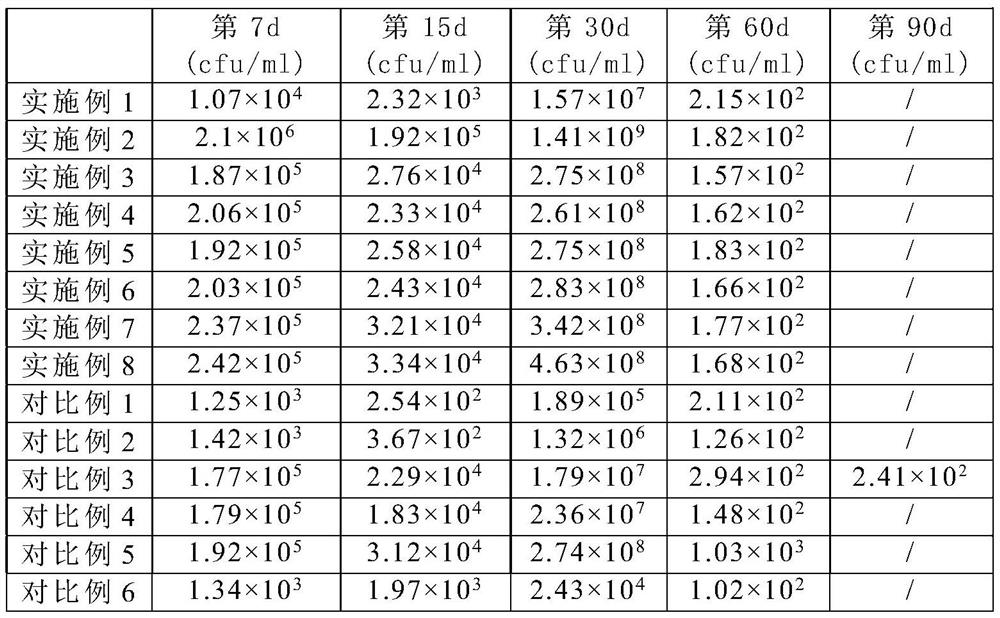

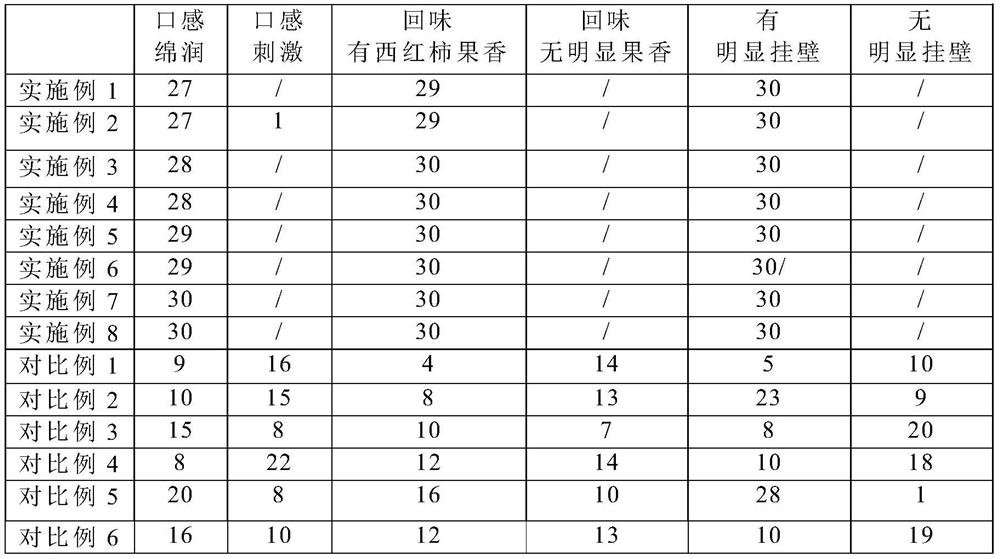

Examples

Embodiment 1

[0035] A kind of brewing process of tomato wine of the present embodiment comprises the following steps,

[0036] S1 tomato pretreatment: select 30kg of tomatoes with a single fruit weight of 150-250g and a sweetness of 9-10; wash, remove the stems, disinfect, crush and sieve to obtain tomato juice for later use;

[0037]S2 saccharification stage: adding white sugar and citric acid to the tomato juice and stirring evenly to obtain a saccharification mixture;

[0038] Wherein, the addition of white granulated sugar is 35% of tomato juice weight, and the addition of citric acid is 0.1% of tomato juice weight;

[0039] S3 fermentation stage: put the saccharification mixture into a sterilized food-grade sealed plastic barrel, and inoculate the saccharification mixture with Oenococcus oeni CECT4727 and fermented glutinous rice, wherein the inoculation amount of Oenococcus oeniCECT 4727 is 1.0×10 6 CFU / mL, the added amount of fermented glutinous rice is 0.3% of the weight of the sa...

Embodiment 2

[0044] A kind of brewing process of tomato wine of the present embodiment comprises the following steps,

[0045] S1 tomato pretreatment: select 30kg of tomatoes with a single fruit weight of 150-250g and a sweetness of 9-10; wash, remove the stems, disinfect, crush and sieve to obtain tomato juice for later use;

[0046] S2 saccharification stage: adding white sugar and citric acid to the tomato juice and stirring evenly to obtain a saccharification mixture;

[0047] Wherein, the addition of white granulated sugar is 45% of tomato juice weight, and the addition of citric acid is 0.2% of tomato juice weight;

[0048] S3 fermentation stage: Add Oenococcus oeni CECT 4727 and fermented glutinous rice to the saccharified mixture, wherein the inoculation amount of Oenococcus oeni CECT 4727 is 1.3×10 8 CFU / mL; the added amount of fermented glutinous rice is 0.6% of the weight of the saccharified mixture;

[0049] After inoculation, stir evenly and seal it, place the plastic bucket...

Embodiment 3

[0054] A kind of brewing process of tomato wine of the present embodiment comprises the following steps,

[0055] S1 tomato pretreatment: select 30kg of tomatoes with a single fruit weight of 150-250g and a sweetness of 9-10; wash, remove the stems, disinfect, crush and sieve to obtain tomato juice for later use;

[0056] S2 saccharification stage: adding white sugar and citric acid to the tomato juice and stirring evenly to obtain a saccharification mixture;

[0057] Wherein, the addition of white granulated sugar is 40% of tomato juice weight, and the addition of citric acid is 0.15% of tomato juice weight;

[0058] S3 fermentation stage: Fermentation stage: put the saccharification mixture into a sterilized food-grade sealed plastic bucket, inoculate the saccharification mixture with Oenococcus oeni CECT 4727 and fermented glutinous rice, among which, the inoculation amount of Oenococcus oeni CECT4727 1.2×10 7 CFU / mL; the added amount of fermented glutinous rice is 0.5% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com