Continuous casting and rolling production process of 3014 aluminum alloy plate strip

An aluminum alloy strip and production process technology, applied in the field of aluminum alloy manufacturing, can solve problems such as inability to perform uniform annealing, affect the processing performance of cast slabs, and complex aluminum alloy components, so as to improve the effect of grain refinement, crystal Fine grain structure and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

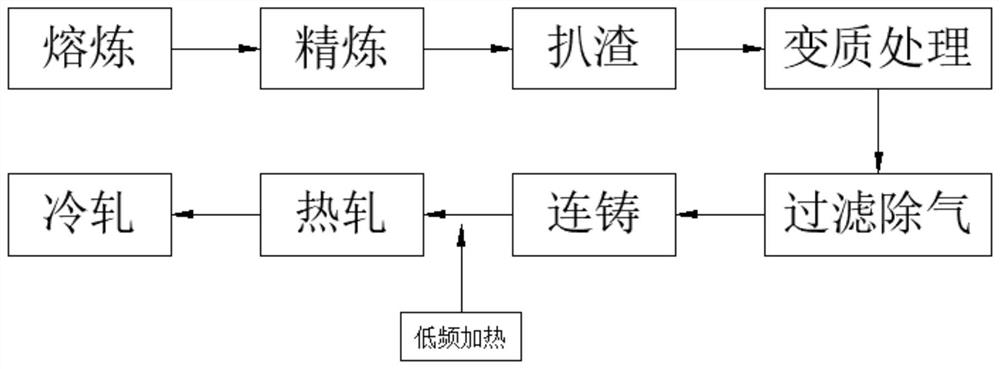

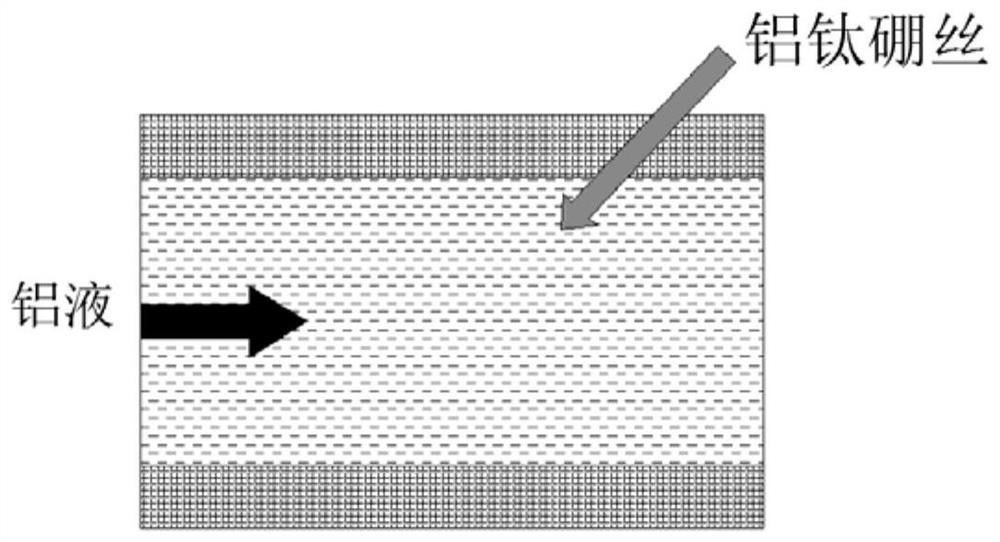

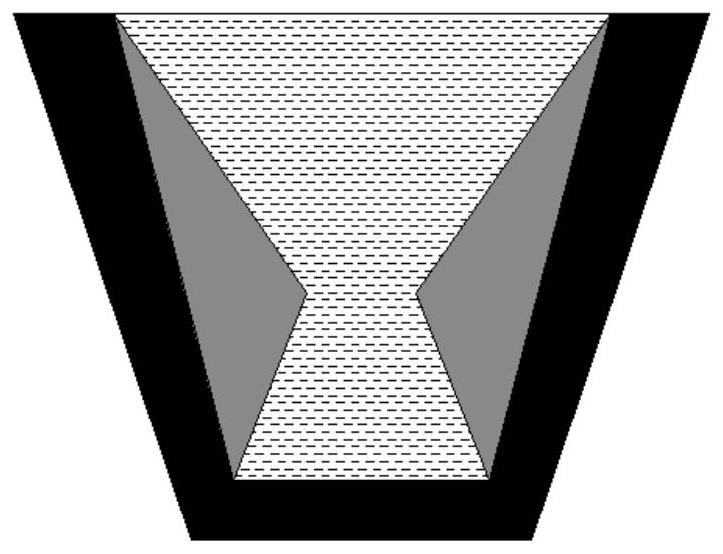

[0029] As shown in the figure, the present invention provides a continuous casting and rolling production process for 3014 aluminum alloy strips.

[0030] Described production process comprises the following steps:

[0031] S1. Melting: Add aluminum ingots or billets, aluminum wires, and electrolytic aluminum liquid to the smelting furnace in sequence. After the aluminum liquid is electromagnetically stirred for ten minutes, samples are taken to analyze the components quickly. According to the ingredients, aluminum-iron alloy blocks, instant silicon blocks, clear Slag agent, etc., raise the temperature in the melting furnace to 730-740°C and perform electromagnetic stirring for ten minutes, remove the scum on the surface, and obtain pure aluminum alloy melt;

[0032] S2. Refining and slag removal: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com