Packaging, aligning and laminating device and packaging, aligning and laminating control method

A bonding device and accommodating technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of narrow frame glue for sealing liquid crystals, difficulty in uniform thickness of liquid crystal cells, small size of LCoS devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Compared with the preparation of traditional transmissive liquid crystal devices, the preparation of LCoS devices is more difficult. The difficulties are mainly reflected in the smaller size of LCoS devices, higher alignment precision requirements for ITO glass and silicon substrates; sealing liquid crystal frame glue Narrower (about 500um), which is mixed with spacers of a certain diameter, it is more difficult to control the uniformity of the overall cell gap in the process; the current mature LCoS process and equipment are basically monopolized by foreign countries, and there are basically no such production conditions in China , especially the LCoS process with a cell gap lower than 3um, is still being explored in China.

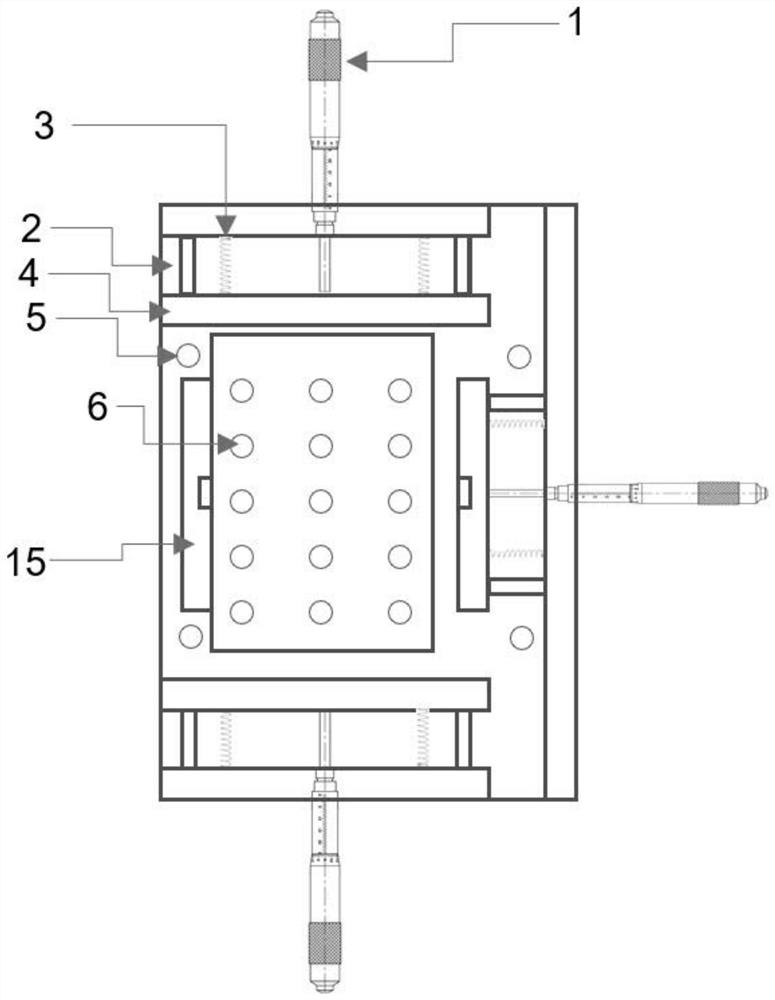

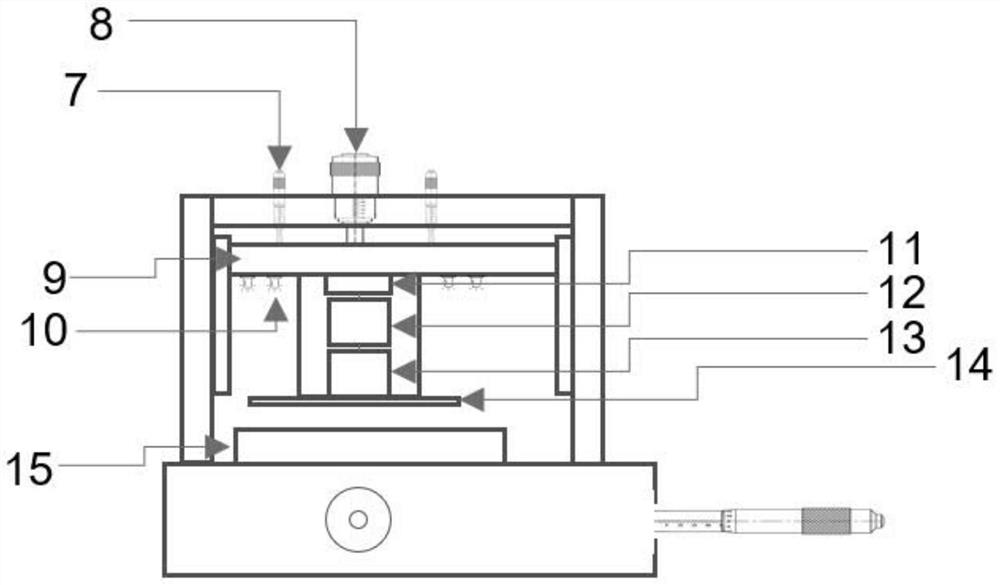

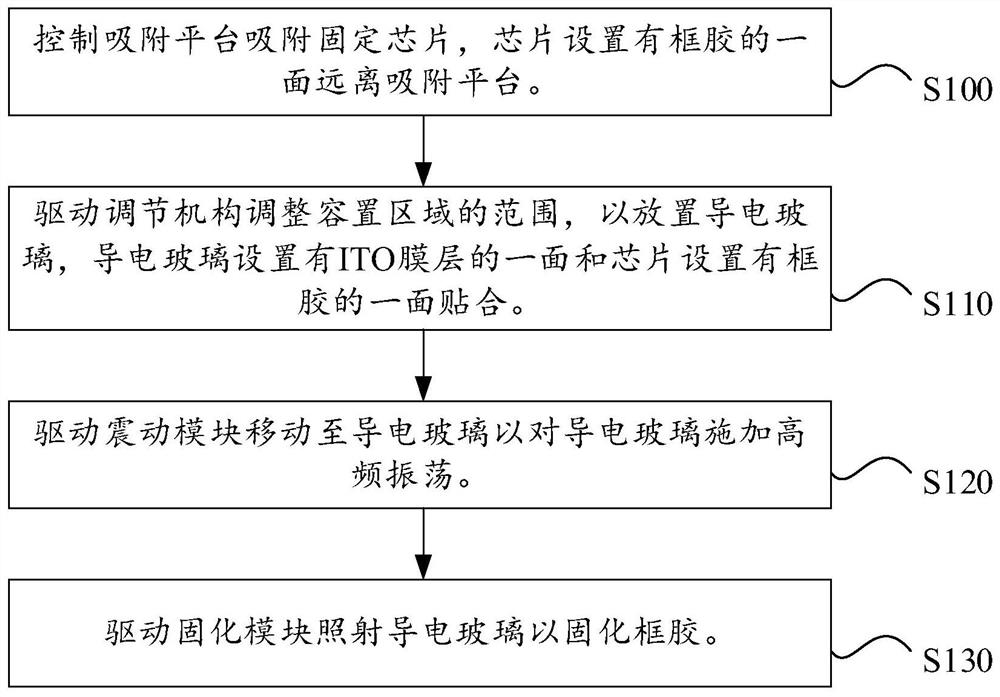

[0032] The packaging alignment bonding device and the packaging alignment bonding control method provided in the embodiments of the present application are mainly aimed at the verification stage of materials before mass production, packaging a sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com