Method and system for optimizing technological parameters of aluminum-zirconium-carbon sliding plate and electronic equipment

A technology of process parameter optimization and aluminum-zirconium-carbon sliding plate, which is applied in neural learning methods, design optimization/simulation, character and pattern recognition, etc., can solve the problem of ignoring correlation, limited number of experiments, and inability to accurately infer each group Issues such as the best proportioning ratio, to achieve the effect of optimizing physical performance and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

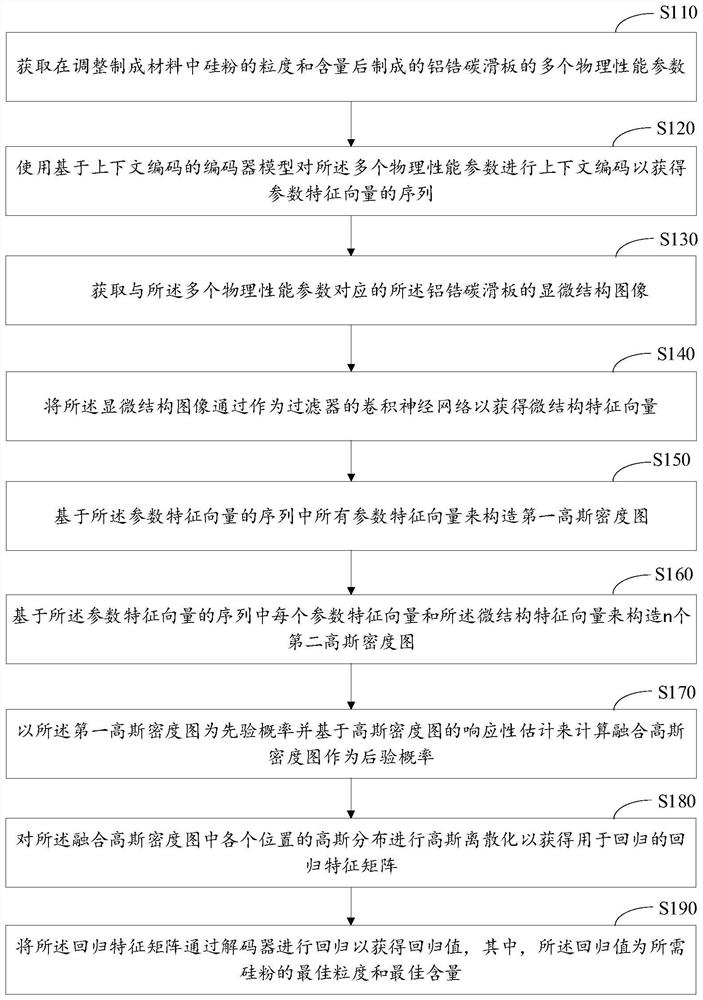

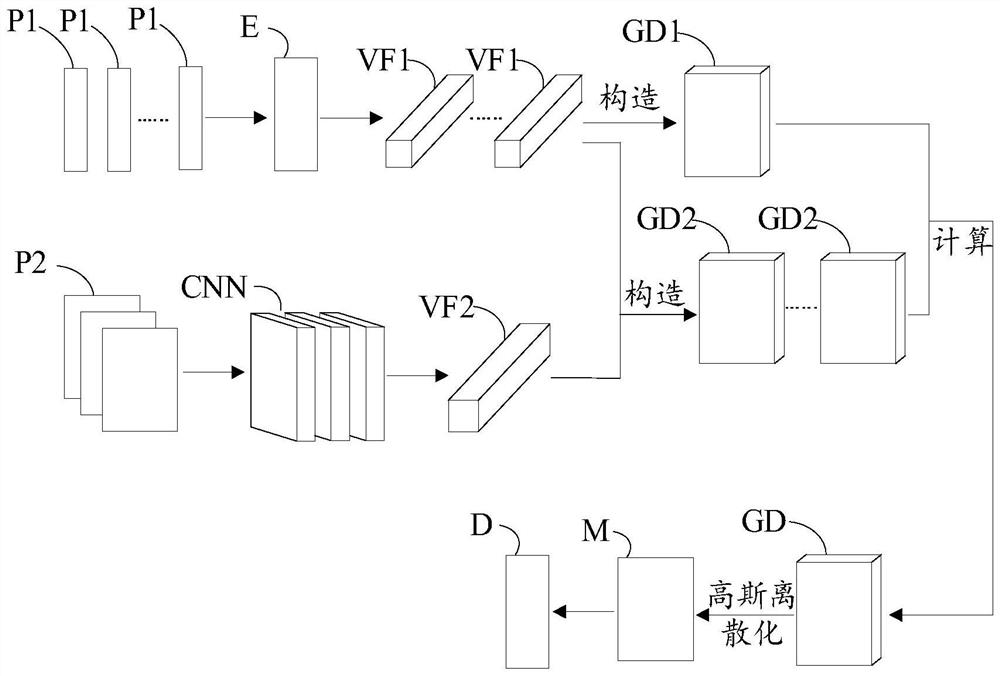

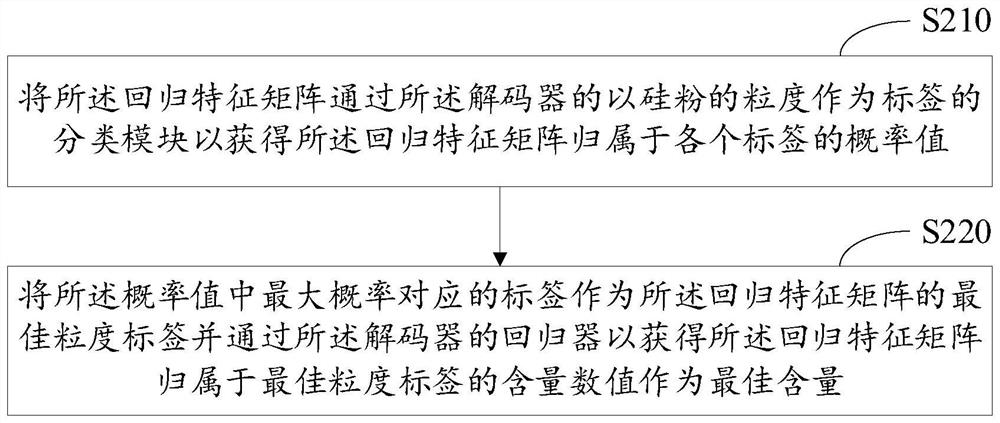

[0061] Hereinafter, exemplary embodiments according to the present application will be described in detail with reference to the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present application, rather than all the embodiments of the present application. It should be understood that the present application is not limited by the exemplary embodiments described here.

[0062] Scenario overview

[0063] As mentioned above, the performance of the aluminum-zirconium-carbon sliding plate is a prerequisite in the assembly process of the sliding nozzle based on the inlaid zirconium ring conjoined body. The study found that silicon powder will affect the physical properties and microstructure of the fired aluminum zirconium carbon sample. Therefore, choosing the best particle size and the best silicon powder content is the key to ensure the quality of fired aluminum-zirconium carbon materials.

[0064] The traditional method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com