Preparation method of pure-phase RP perovskite thin film

A perovskite and thin film technology, applied in the field of new semiconductor optoelectronics, can solve the problem of difficulty in generating pure equals, and achieve the effects of low cost, good environmental stability, and simple and feasible preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

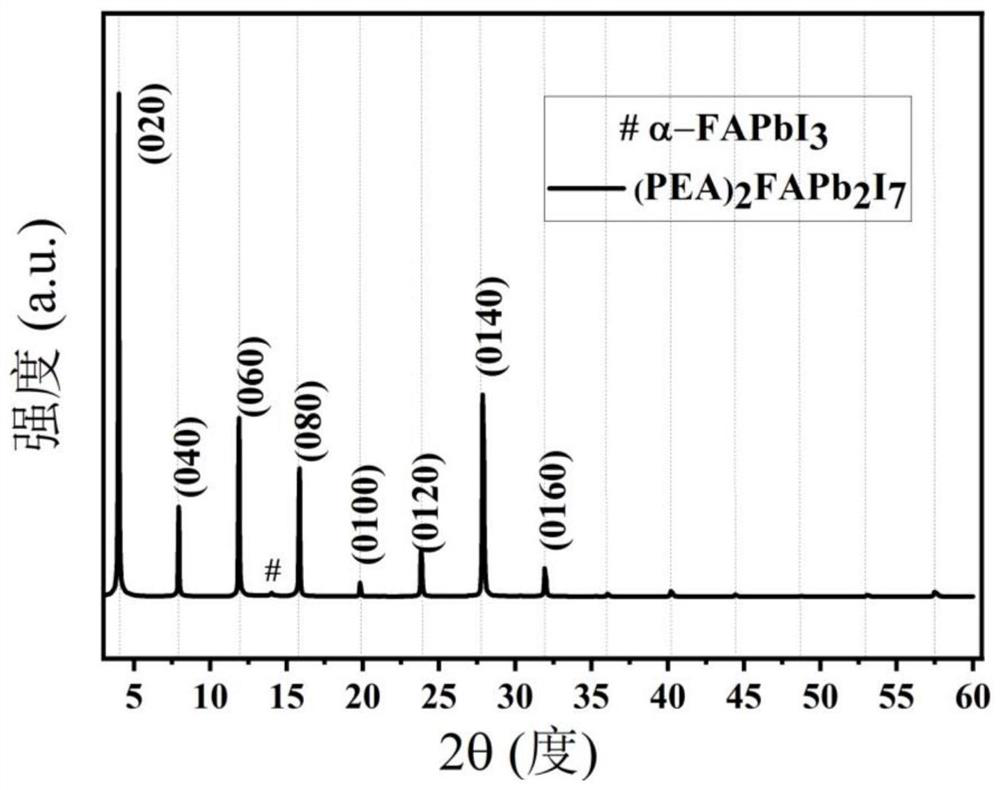

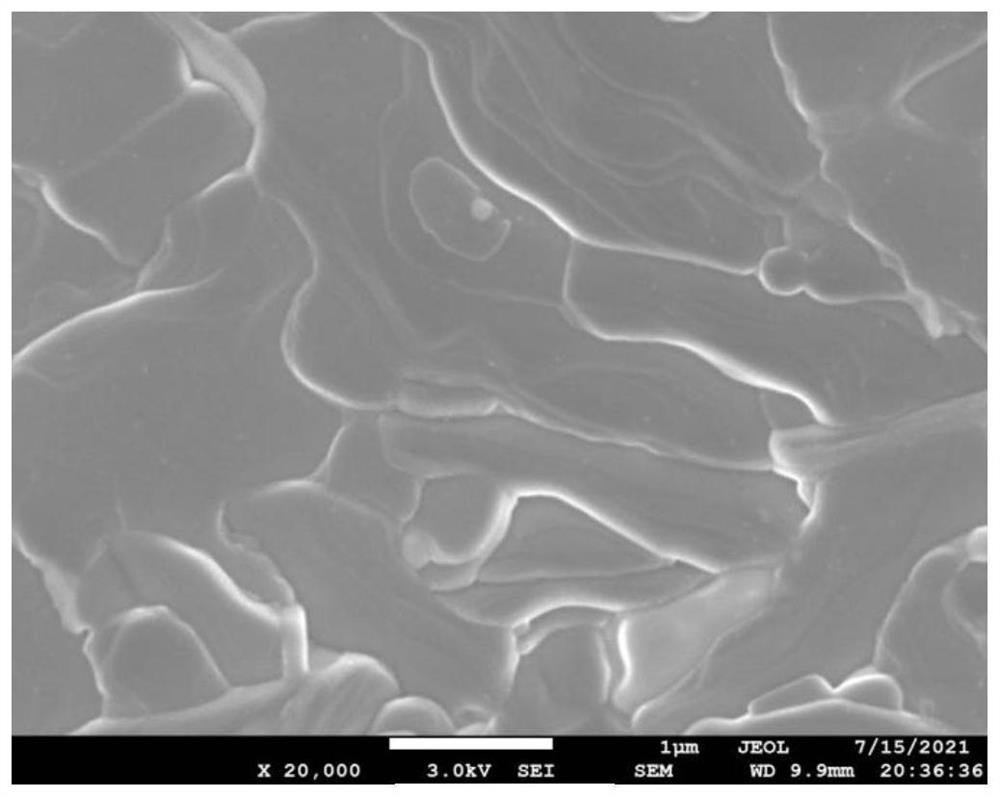

[0040] Pure RP Phase Perovskite (PEA) 2 FAPb 2 I 7 Film preparation

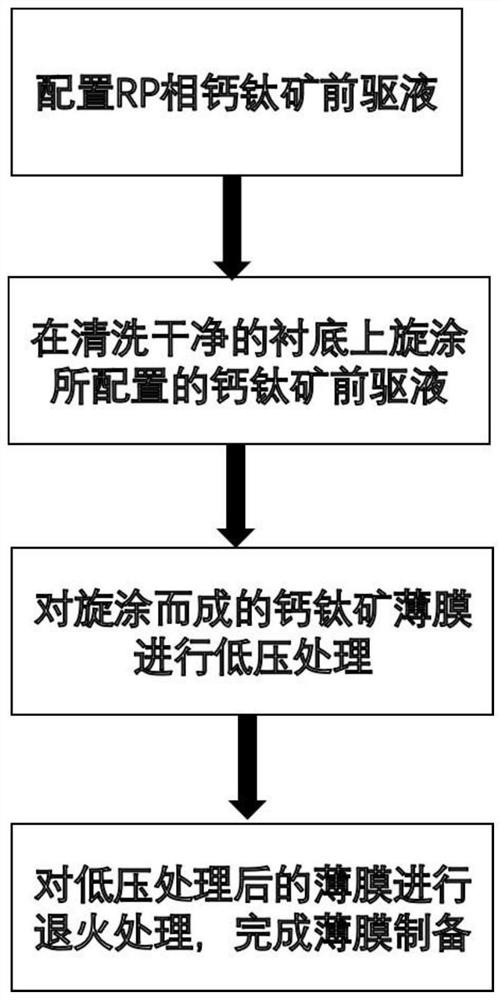

[0041] The preparation process is as figure 1 shown, including the following steps:

[0042] Step 1: Add 0.4610g (1.0mmol) of PbI 2 , 0.2490g (1.0mmol) of PEAI (C 6 h 5 CH 2 CH 2 NH 3 1), 0.0860g (0.5mmol) of FAI (HC (NH 2 ) 2 1) be dissolved in the mixed solution of DMF and NMP of 1ml, and add the methylammonium chloride (MACl) of 0.0236g (0.35mmol) as additive, wherein the volume ratio of DMF:NMP is 9:1, and preparation concentration is 1mol / L perovskite precursor solution.

[0043] Step 2: Utilize the rotary coating equipment (KW-4A type desktop glue leveler), on the ITO substrate (area is 4cm 2 ) on the deposition precursor solution. Among them, the rotation speed of the spin coating equipment is 4000rpm, the spin time is 10s, the volume of the perovskite precursor for each spin coating is 50μl, the temperature is controlled at 22°C and the humidity is controlled at 60% during the spin coa...

Embodiment 2

[0046] Pure RP Phase Perovskite (PMA) 2 FAPb 2 I 7 Film preparation

[0047] Different from Example 1, the solute in the perovskite precursor is 0.461g (1.0mmol) of PbI 2 , 0.233g (1.0mmol) of PMAI (C 7 h 8 IN), 0.0860g (0.5mmol) of FAI (HC (NH 2 ) 2 1) Dissolve in 1 ml of a mixed solution of DMF and NMP (DMF:NMP=9:1), and add 0.0236 g (0.35 mmol) of methyl ammonium chloride (MACl) as an additive.

Embodiment 3

[0049] Pure RP Phase Perovskite (BA) 2 FAPb 2 I 7 Film preparation

[0050] Different from Example 1, the solute in the perovskite precursor is 0.4610g (1.0mmol) of PbI 2 , 0.201g (1.0mmol) of BAI (CH 3 CH 2 CH 2 NH 3 1), 0.0860g (0.5mmol) of FAI (HC (NH 2 ) 2 1) Dissolve in 1 ml of a mixed solution of DMF and NMP (DMF:NMP=9:1), and add 0.0236 g (0.35 mmol) of methyl ammonium chloride (MACl) as an additive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com