Nitrogen-doped carbon-loaded platinum-zinc alloy electrocatalyst as well as preparation method and application thereof

A nitrogen-doped carbon and electrocatalyst technology, which is applied in circuits, electrical components, battery electrodes, etc., can solve the problems of poor catalyst durability and catalytic activity, restrictions on the wide application of platinum, and high application cost of platinum, and achieve easy large-scale Improvement of production and redox efficiency and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

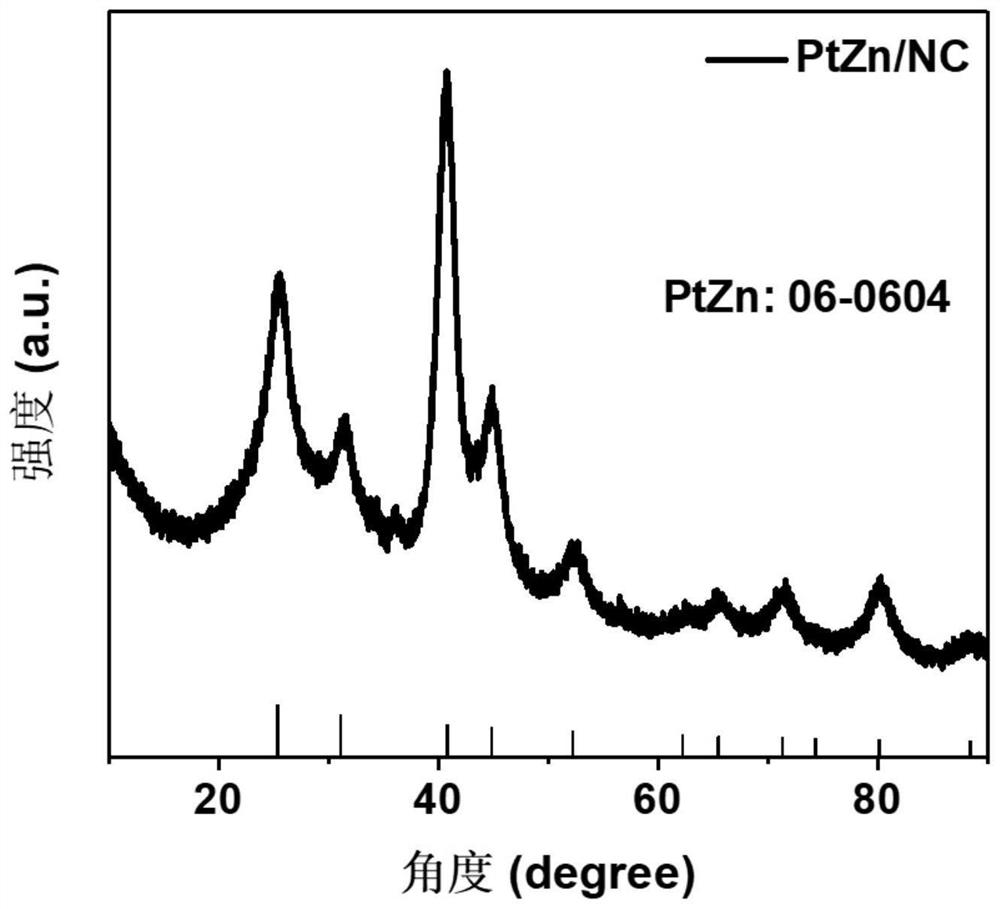

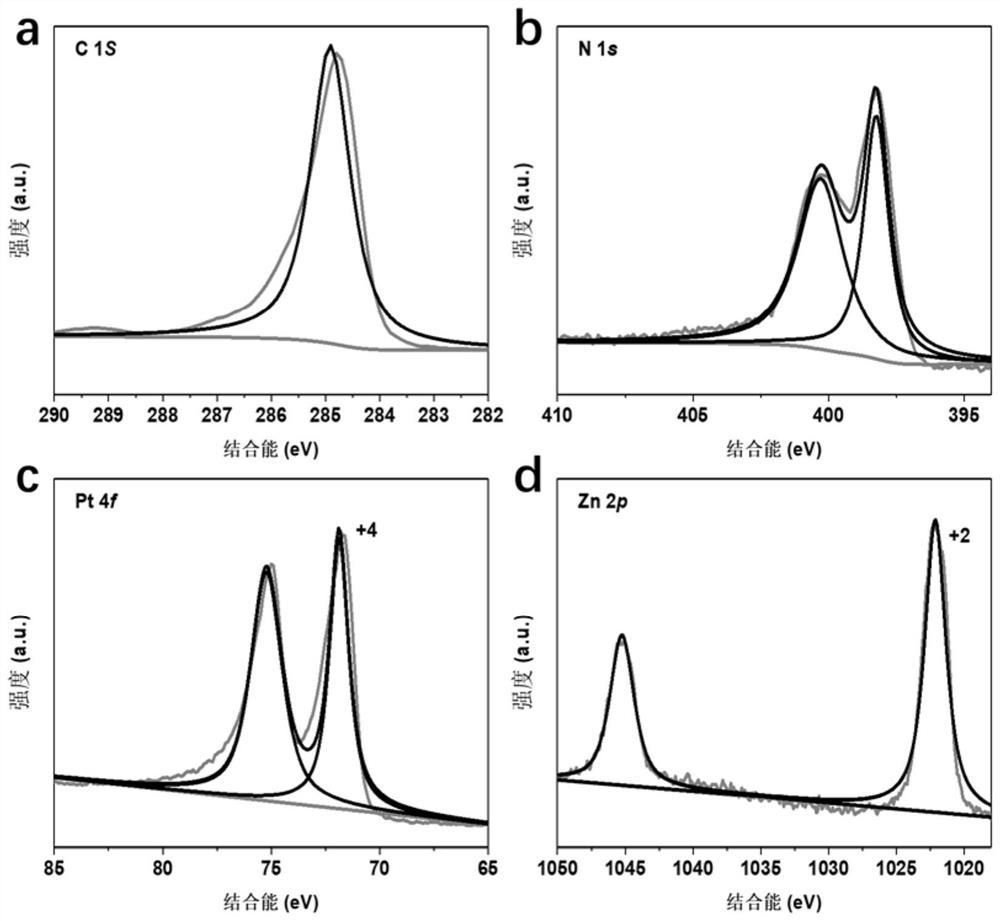

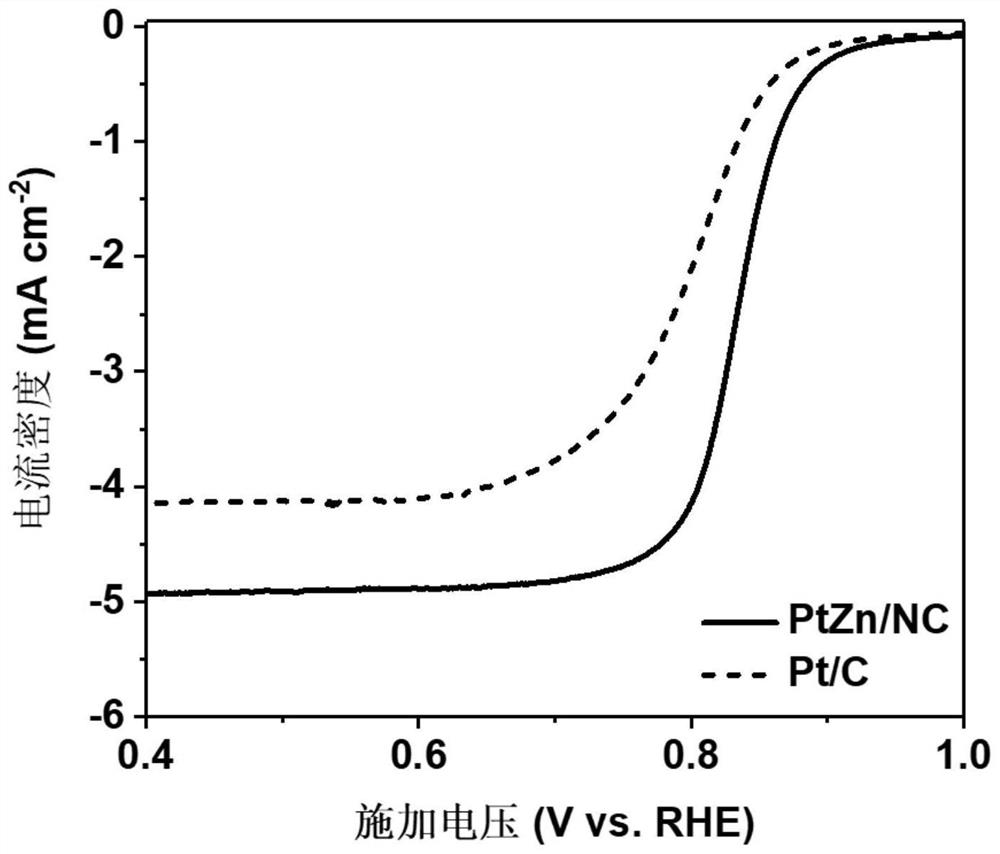

Embodiment 1

[0026] A preparation method of a nitrogen-doped carbon-supported platinum-zinc alloy electrocatalyst, adding a nitrogen source, a zinc source, a platinum source, and a carbon source into a container filled with acetone according to the following mass ratio, wherein the nitrogen element in the nitrogen source hydroxylamine hydrochloride is 5.6 mg, 24 mg of carbon element in carbon black as a carbon source, 1.7 mg of zinc element in zinc acetylacetonate as a zinc source, 6.9 mg of platinum element in platinum source platinum acetylacetonate, and the above-mentioned weighed hydroxylamine hydrochloride, carbon black, platinum acetylacetonate, and acetylacetonate Dissolve zinc in a container containing 20ml (15760mg) of acetone to make it evenly dispersed, then stir it at 80°C until it becomes viscous, then put it in an oven at 60°C for drying treatment, after it is completely dry, put it in a tube furnace Calcination was carried out at 950°C, nitrogen was used as protective gas, py...

Embodiment 2

[0030] A preparation method of a nitrogen-doped carbon-supported platinum-zinc alloy electrocatalyst, adding a nitrogen source, a zinc source, a platinum source, and a carbon source into a container filled with acetone according to the following mass ratio, wherein the nitrogen element in the nitrogen source hydroxylamine hydrochloride is 8.4 mg, 30mg of carbon element in carbon black as a carbon source, 3.5mg of zinc element in zinc acetylacetonate as a zinc source, 10.4mg of platinum element in platinum acetylacetonate as a platinum source, and the above-mentioned weighed hydroxylamine hydrochloride, carbon black, platinum acetylacetonate, and acetylacetonate Dissolve zinc in a container containing 20ml of acetone that is 15760mg of acetone, make it evenly dispersed, then stir it at 80°C until it becomes viscous, then put it in an oven at 100°C for drying treatment, and put it in the tube after it is completely dry. Calcination was carried out at 950°C in a type furnace, neon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com