Preparation method of phase change heat reservoir of electronic equipment

A technology for electronic equipment and heat storage, which is applied in the field of preparation of phase change heat storage for electronic equipment, and can solve the difficulty of preparing and installing the internal heat conduction core 2, increasing the thermal resistance of the heat conduction core 2, and leakage of liquid phase change materials 3 and other problems, to achieve the effect of shortening the process flow and manufacturing cycle, short manufacturing cycle, and high utilization rate of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

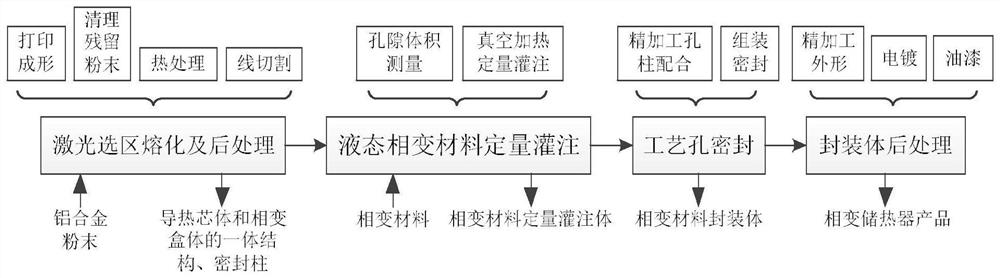

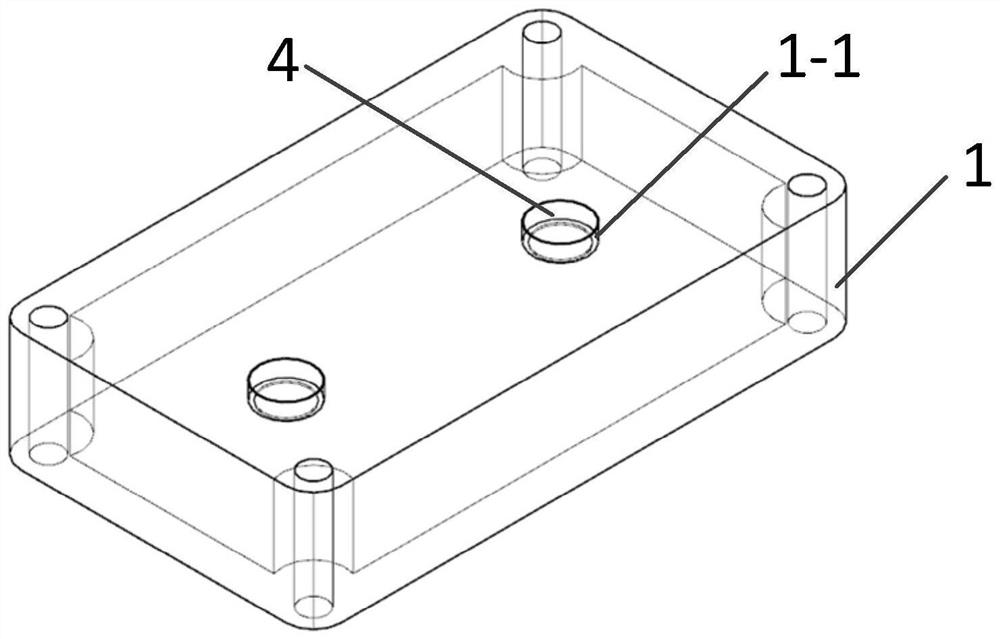

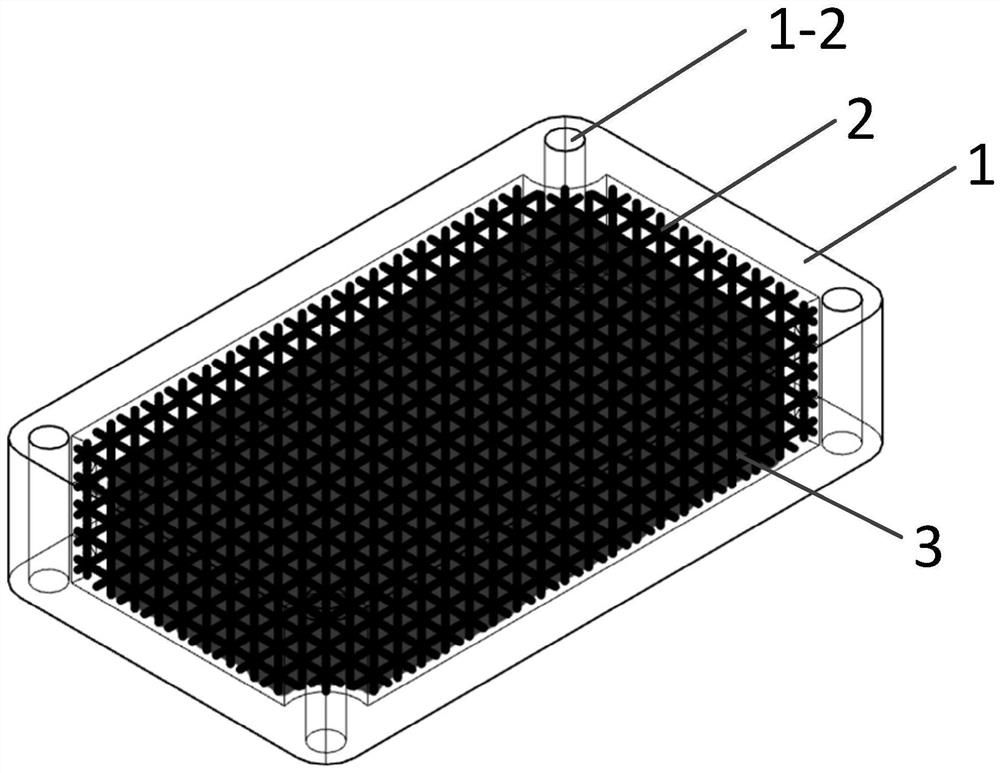

[0032] refer to figure 1 , figure 2 . The process hole 1-1 of the box body is welded and joined with the sealing column to form a cavity structure box body with uniform thickness on each surface; a porous lattice structure is designed, and the diameter of the lattice rod forms a gradient change in multiple directions The three-dimensional model of the thermally conductive core 2 conforming to the inner cavity of the phase change box 1 is assembled to the inner cavity of the phase change box 1 provided with two process holes 1-1 to form the thermally conductive core 2 and the phase change box 1 The integrated model of the integrated model; the aluminum alloy powder is used to print and form by laser selective melting equipment, and after cleaning the residual powder, heat treatment, wire cutting and other processes, the integrated structure and sealing of the phase change heat storage core 2 and the phase change box 1 are obtained. Column; the low-temperature solid-liquid ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rod diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com