Catalyst for treating leaked ammonia of selective catalytic reduction device and preparation method of catalyst

A device leakage and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of deteriorating diesel engine NOx emissions, high cost of raw materials, poor resistance to sulfur and heat aging, etc., to achieve Efficient collaborative purification and reliable purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

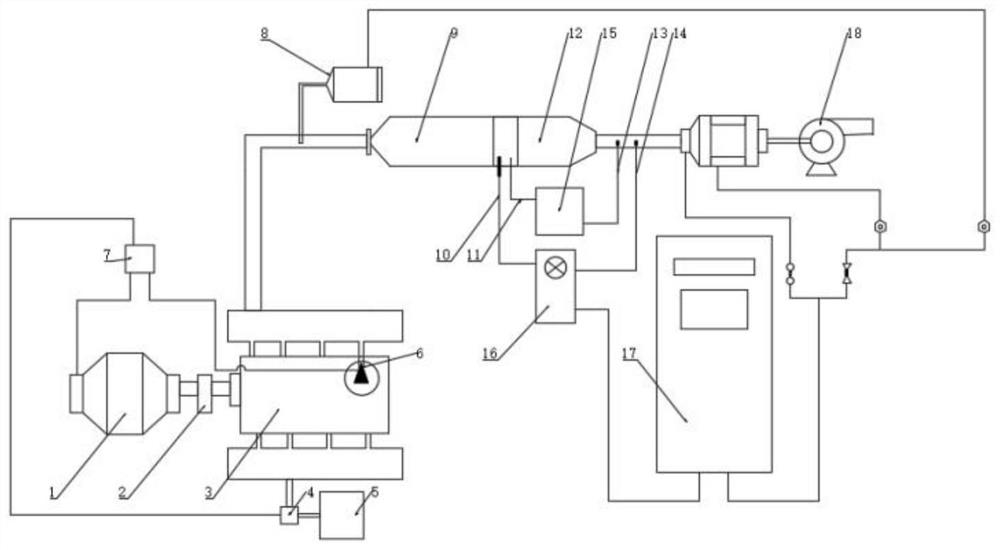

Image

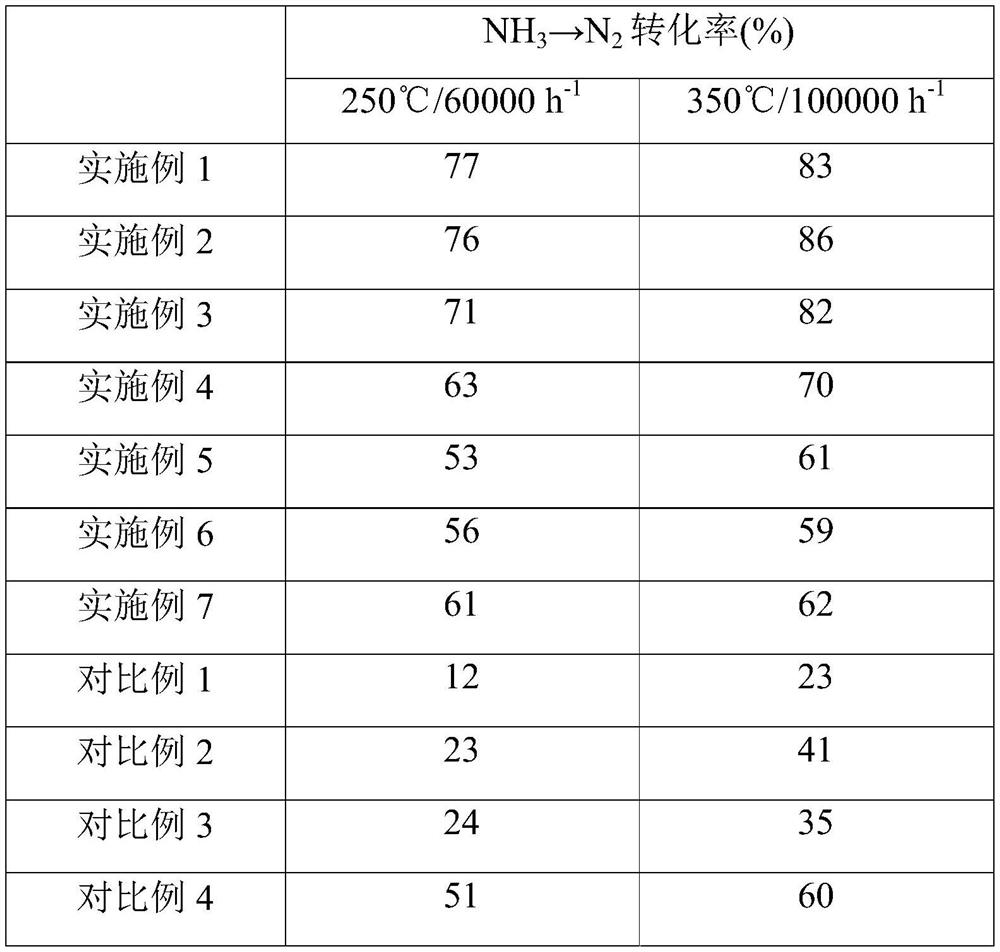

Examples

Embodiment 1

[0072] (1) Catalyst composition design:

[0073] External active coating: The mass percentage of Cu and ZSM-5 molecular sieve in the external active component of the external active coating is designed to be 5%: 95%, and CeO in the external auxiliary material 2 , γ-Al 2 o 3 and SiO 2 The mass percentage: 15%: 65%: 20%, γ-Al in the external accessories 2 o 3 Medium pure γ-Al 2 o 3 γ-Al converted from aluminum sol 2 o 3 The mass percentage is 85%: 15%, the mass percentage of the external active component and the external auxiliary material is: 15%: 85%, and it is planned to prepare the external active coating slurry that can be converted into 2000g external active coating at one time.

[0074] Inner active coating: Pd and La in the inner active components of the inner active coating are designed separately 0.8 Ce 0.2 mn 0.7 Ni 0.3 o 3 The mass percentage of perovskite composite oxide is 5%: 95%, CeO in the auxiliary material 2 -ZrO 2 Solid solution and γ-Al 2 o ...

Embodiment 2

[0081] (1) Catalyst composition design:

[0082] External active coating: The mass percentages of Cu and ZSM-5 molecular sieve in the external active components of the external active coating are designed to be 10%: 90%, and CeO in the external auxiliary material 2 , γ-Al 2 o 3 and SiO 2 The mass percentage is 5%: 85%: 10%, and the γ-Al in the external accessories 2 o 3 Medium pure γ-Al 2 o 3 γ-Al converted from aluminum sol 2 o 3 The mass percentage is 80%: 20%, the mass percentage of the external active component and the external auxiliary material is 5%: 95%, and it is planned to prepare the external active coating slurry that can be converted into 2000g external active coating at one time.

[0083] Inner active coating: Pd and La in the inner active components of the inner active coating are designed separately 0.8 Ce 0.2 mn 0.7 Ni 0.3 o 3 The mass percentage of perovskite composite oxide is 10%: 90%, CeO in the auxiliary material 2 -ZrO 2 Solid solution and...

Embodiment 3

[0090] (1) Catalyst composition design:

[0091] External active coating: The mass percentages of Cu and ZSM-5 molecular sieve in the external active components of the external active coating are designed to be 10%: 90%, and CeO in the external auxiliary material 2 , γ-Al 2 o 3 and SiO 2 The mass percentage is 10%: 70%: 20%, and the γ-Al in the external accessories 2 o 3 Medium pure γ-Al 2 o 3 γ-Al converted from aluminum sol 2 o 3 The mass percentage is 85%: 15%, and the mass percentage of the external active component and the external auxiliary material is 15%: 85%. It is planned to prepare an external active coating slurry that can be converted into a 2000g external active coating at one time.

[0092] Inner active coating: Pd and La in the inner active components of the inner active coating are designed separately 0.8 Ce 0.2 mn 0.7 Ni 0.3 o 3 The mass percentage of perovskite composite oxide is 10%: 90%, CeO in the auxiliary material 2 -ZrO 2 Solid solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com