Pellet roasting flue gas denitration and desulfurization device and method based on chain grate-rotary kiln

A technology of chain grate and rotary kiln is applied in the field of flue gas treatment, which can solve the problems of untreated flue gas, high flue gas temperature, and inability to discharge directly, so as to improve the utilization efficiency, reduce the energy consumption and operation cost of the device, and achieve high efficiency. The effect of synergistic purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

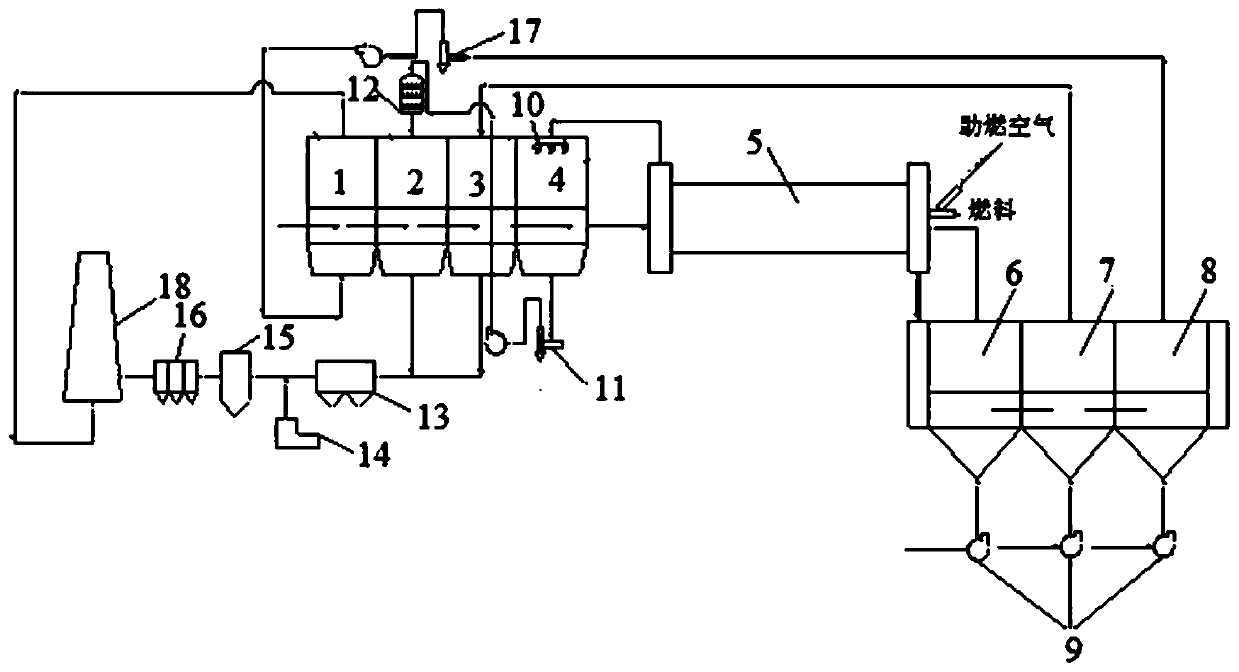

[0081] This embodiment provides a pellet roasting flue gas denitrification and desulfurization device based on a grate machine-rotary kiln. The structural diagram of the device is as follows figure 1 As shown, it includes a reaction system and a flue gas treatment system, the reaction system includes a chain grate and a rotary kiln 5 connected in sequence, and the flue gas treatment system includes an SNCR unit 10, an SCR unit 12, an ozone oxidation unit 14 and sulfur nitric acid Absorption unit 15, the flue gas outlet of the rotary kiln 5 passes through the SNCR unit 10 and is connected to the gas inlet of the grate machine, and the gas outlet of the grate machine is connected to the SCR unit 12, the ozone oxidation unit 14 and the sulfur nitric acid absorption unit in sequence Unit 15.

[0082]The grate machine is successively divided into a first drying section 1, a second drying section 2, a first preheating section 3 and a second preheating section 4 along the pellet feed...

Embodiment 2

[0092] This embodiment provides a pellet roasting flue gas denitrification and desulfurization device based on a grate machine-rotary kiln. The structure of the device refers to the structure in Embodiment 1, and the only difference is: the sulfur and nitrate absorption unit 15 The semi-dry desulfurization device is a spray drying tower.

Embodiment 3

[0094] This embodiment provides a method for denitrification and desulfurization of pellet roasting flue gas based on a grate machine-rotary kiln. The method is carried out using the device in Embodiment 1, including the following steps:

[0095] (1) The pelletized material is dried and preheated by the grate machine and then transported to the rotary kiln 5. The pelletized material is roasted in countercurrent contact with the gas fuel, and the NO in the roasting flue gas x The concentration is 350mg / Nm 3 , SO 2 The concentration is 790mg / Nm 3 , the concentration of particulate matter is 100mg / Nm 3 , the flue gas is first subjected to SNCR treatment at a temperature of 1000°C, and ammonia gas is injected during the SNCR treatment process, and the ammonia gas and the NO in the roasting flue gas x The molar ratio is 1:1;

[0096] (2) The flue gas treated by SNCR enters the second preheating section 4 of the grate for heat exchange and cooling to preheat the pellet material....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com