Method for connecting graphite film and copper

A connection method and technology of graphite film, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as easy cracks, high melting point of graphite film, and inability to form intermetallic compounds, so as to reduce residual stress and reduce welding The effect of seam width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

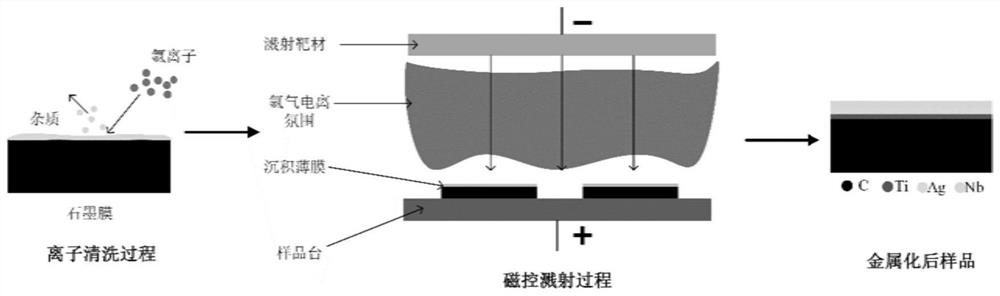

[0025] A method for diffusion connection between a high thermal conductivity graphite film and copper in this embodiment includes the following steps:

[0026] Step 1. Put the high thermal conductivity graphite film into the acetone solution and ultrasonically clean it for 10min-20min to remove the oil stains and impurities on the surface;

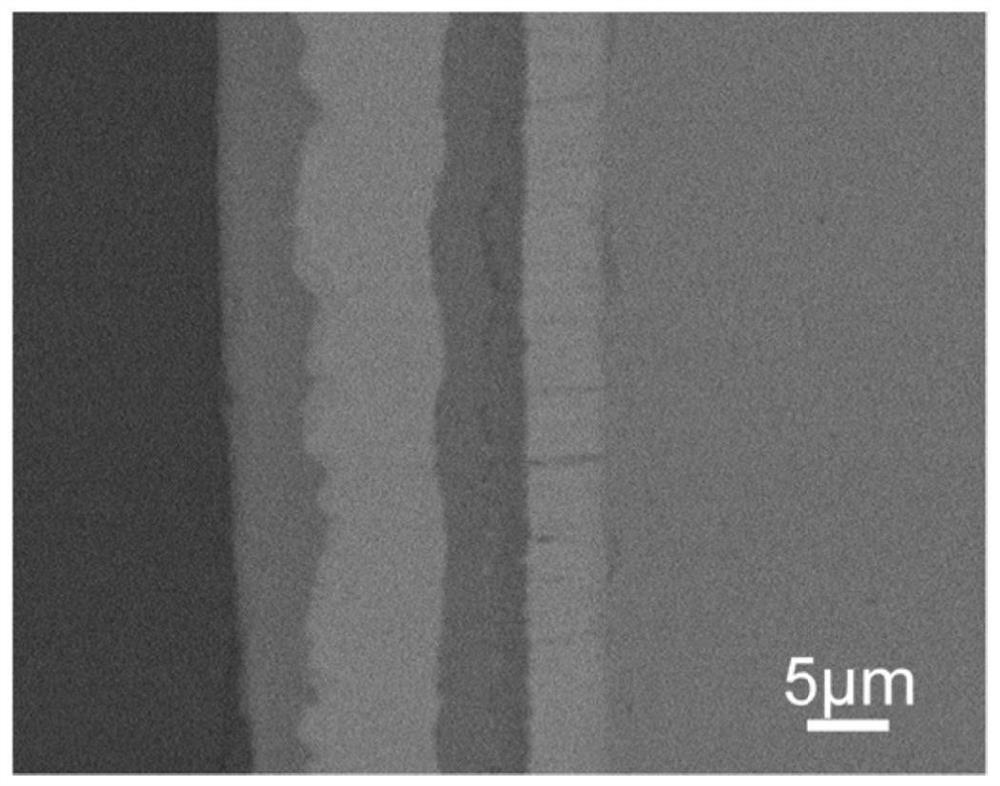

[0027] Step 2: Place the graphite film obtained in step 1 in a magnetron sputtering chamber, control the temperature to room temperature, and evacuate to make the air pressure inside the chamber less than 5×10 -3 Pa, and then pass 3sccm of argon to maintain the pressure at 2 × 10 -3 Pa±0.5Pa, the bias voltage was adjusted to 400V, and the surface of the graphite film was bombarded with argon ions for 10min. This process was ion cleaning, and then magnetron sputtering was started; the parameters of the metal layer: the power was 350W, and the Ti-plating time was 60min. The Ag plating time is 20min, and the Nb plating time is 20min;

[002...

Embodiment 2

[0032] A method for diffusion connection between a high thermal conductivity graphite film and copper in this embodiment includes the following steps:

[0033] Step 1. Put the high thermal conductivity graphite film into the acetone solution and ultrasonically clean it for 10min-20min to remove the oil stains and impurities on the surface;

[0034] Step 2: Place the graphite film obtained in step 1 in a magnetron sputtering chamber, control the temperature to room temperature, and evacuate to make the air pressure inside the chamber less than 5×10 -3 Pa, and then pass 3sccm of argon to maintain the pressure at 2 × 10 -3 Pa±0.5Pa, the bias voltage is adjusted to 400V, and the surface of the graphite film is bombarded with argon ions for 10min. This process is ion cleaning, and then magnetron sputtering is started; the parameters of the metal layer: the power is 400W, and the Ti-plating time is 90min. The Ag plating time is 50min, and the Nb plating time is 60min;

[0035] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com