High tellurite tolerant bacterium-mediated synthesized biological tellurium nano-particles and antibacterial application of high tellurite tolerant bacterium-mediated synthesized biological tellurium nano-particles

A technology of high tellurite and synthetic biology, applied in the direction of microorganisms, microorganism-based methods, biochemical equipment and methods, etc., to achieve the effects of simple preservation, safe and controllable acquisition methods, and stable biological functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

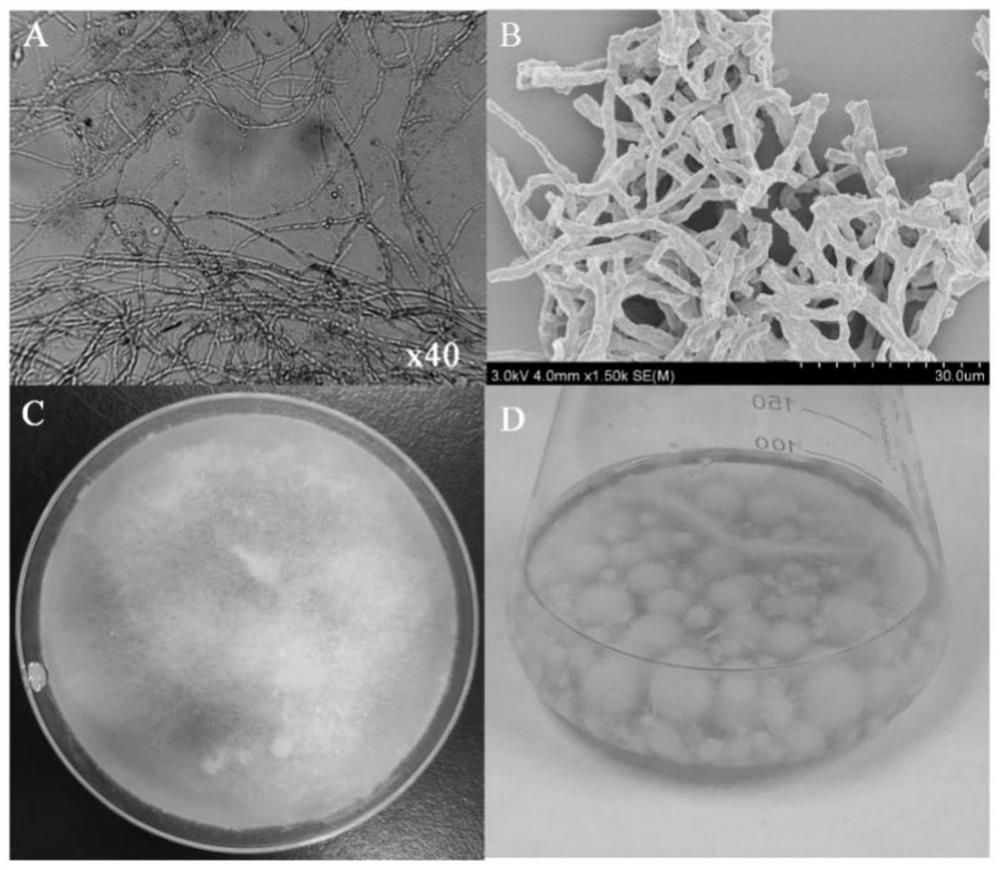

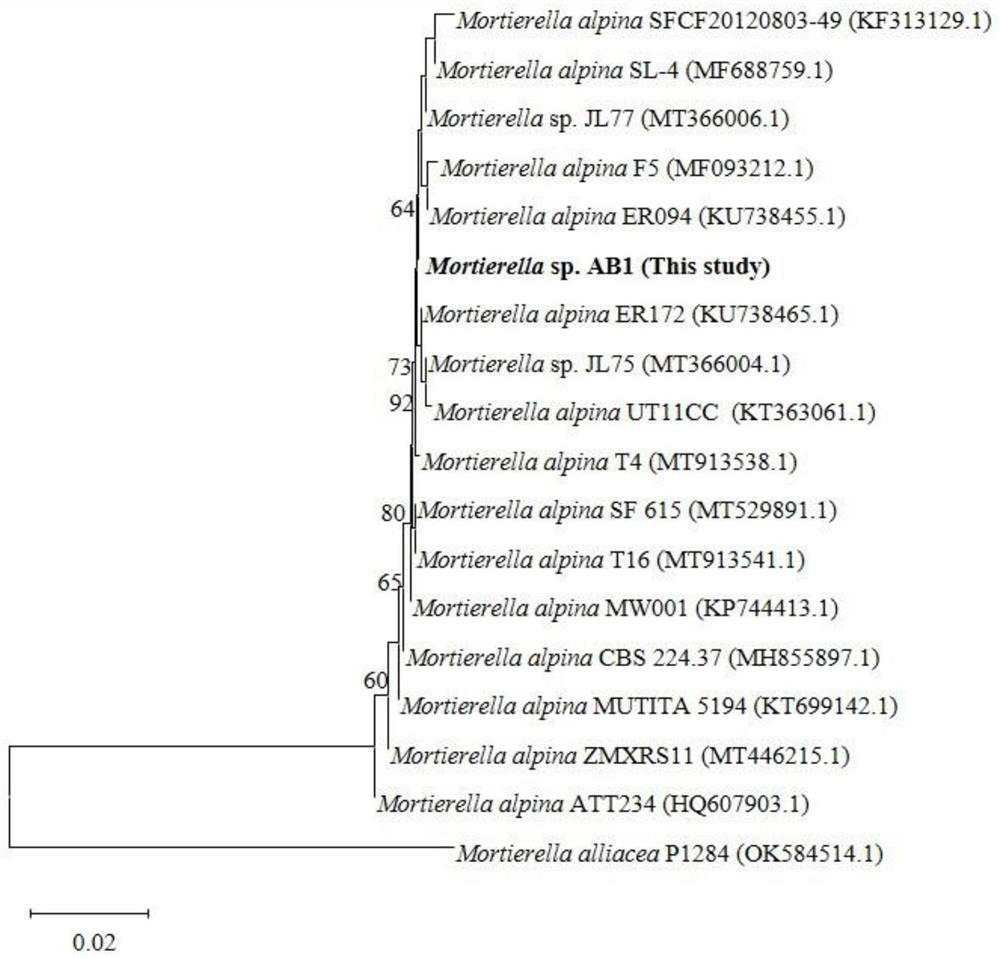

[0037] Example 1 Isolation, screening and identification of tellurite-tolerant strains

[0038] (1) Select 1g of waste dump soil sample, add 10mL of sterilized normal saline with a mass volume ratio of 0.85%, and mix in a shaker at 37°C and 200rpm for 30min;

[0039] (2) Heat to dissolve 100mL solid LB medium (tryptone 10g, yeast extract 5g, sodium chloride 10g, agar 20g, add dd H 2 (2) Dilute to 1000mL, 121°C, use after 20min sterilization), add potassium tellurite (KT) with a final concentration of 0.1mmol / L 2 TeO 3 ), pour the plate, take 200 μL of the above-mentioned dissolved soil sample, spread it evenly on the surface of the plate, and incubate at 37°C for 16 hours;

[0040] (3) Select black mycelium, inoculate to solid PDA plate (potato 200g, glucose 20g, agar 20g, add ddH 2 (2) Dilute to 1000mL, 121°C, use after 20min sterilization), and cultivate at 28°C for 6-7 days;

[0041] (4) Cut small pieces of solid PDA (containing mycelium), add it to 100mL liquid PDA, an...

Embodiment 2

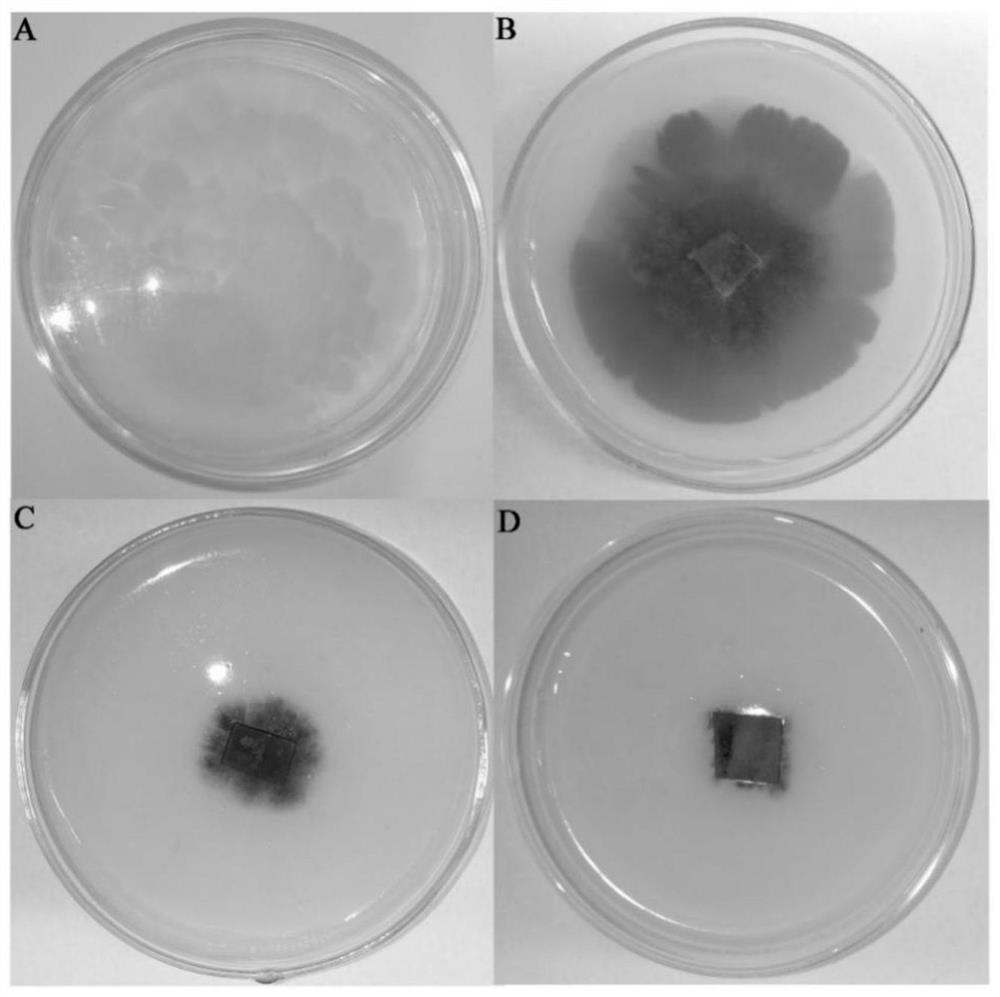

[0048] Example 2 Tellurite tolerance test

[0049] (1) Optimizing culture medium: the primary shake flask uses corn flour medium (corn flour 40g / L, KNO 3 2 g / L, NaHPO 4 1g / L, MgSO 4 ·7H 2 O 0.3g / L), seal the medium after preparation, and sterilize at 121°C for 20min. The secondary shake flask uses improved PDA medium (potato 200g / L, KNO 3 2g / L, NaHPO 4 1g / L, MgSO 4 ·7H 2 (0.3g / L), the culture medium was prepared and sealed, and sterilized at 121°C for 20 minutes;

[0050] (2) Using the slant strain in Example 1, cut small pieces of solid PDA (containing mycelia), add it to a 100mL first-stage shaker flask, and cultivate it for 3 to 5 days at 28°C and 200r / min. , to obtain an appropriate amount of liquid bacteria;

[0051] (3) Take 5mL of the liquid strains in the primary shake flask, add them to the 100mL secondary shake flask, and cultivate them for 3 to 5 days at 28°C and 200r / min to obtain a large amount of liquid strains;

[0052] (4) Use the culture medium form...

Embodiment 3

[0057] Example 3 Tellurite reduction test

[0058] (1) Make a standard curve: a. Prepare 5 mg / mL sodium borohydride. b. Prepare 10mM K 2 TeO 3 , and carried out 8 times of serial dilution, leaving 0 value. c. Prepare 300 mM PBS (pH 7). d. Add 50 μL sodium borohydride, 50 μL potassium tellurite and 200 μL PBS into a 500 μL centrifuge tube, mix well, and react at 60°C for 10 minutes. e. Take 200 μL of the reaction solution into a 96-well plate, at OD 500 Measure the absorbance and make a standard curve;

[0059] (2) Using the secondary shake flask liquid strain in Example 2, take 5 mL of the bacterial liquid and add it to 100 mL of the improved PDA liquid medium (containing potassium tellurite with a final concentration of 0.5 mM);

[0060] (3) Take 500 μL of the culture medium every 24 hours, centrifuge at 12,000 rpm for 10 minutes, take 50 μL of the sample, mix with 50 μL of sodium borohydride and 200 μL of PBS, and react at 60°C for 10 minutes, then take 200 μL of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com