Platinum catalyst and preparation method and application thereof

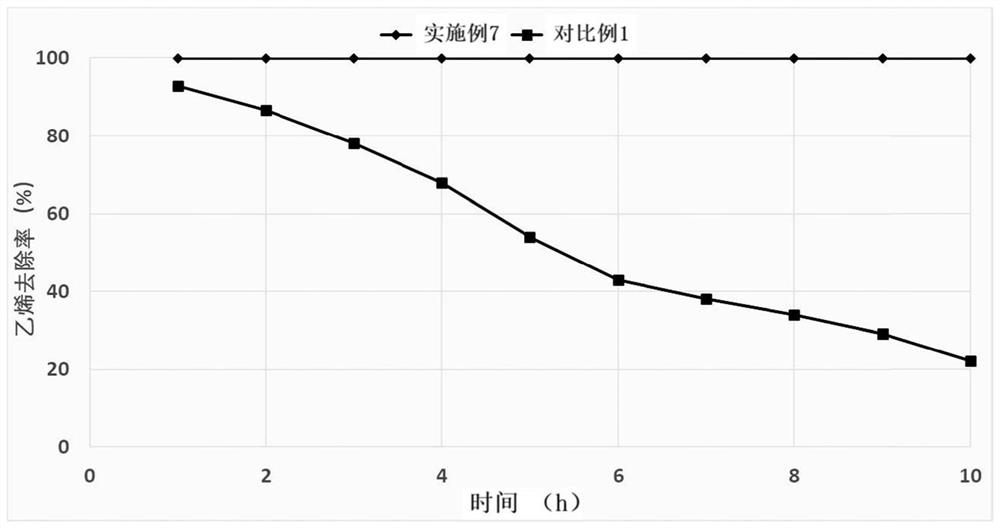

A platinum catalyst and catalytic oxidation technology, applied in the field of catalysis, can solve the problems of low ethylene treatment efficiency, complicated preparation process of platinum catalyst, and high use cost, and achieve the effects of low cost, high atom utilization rate, and no pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

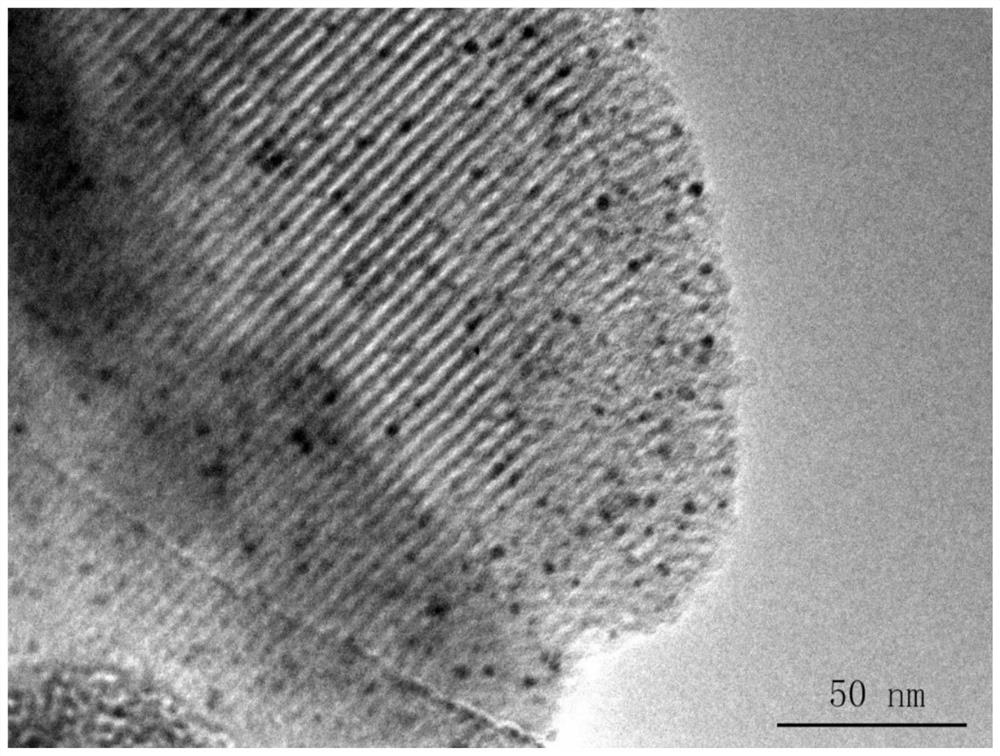

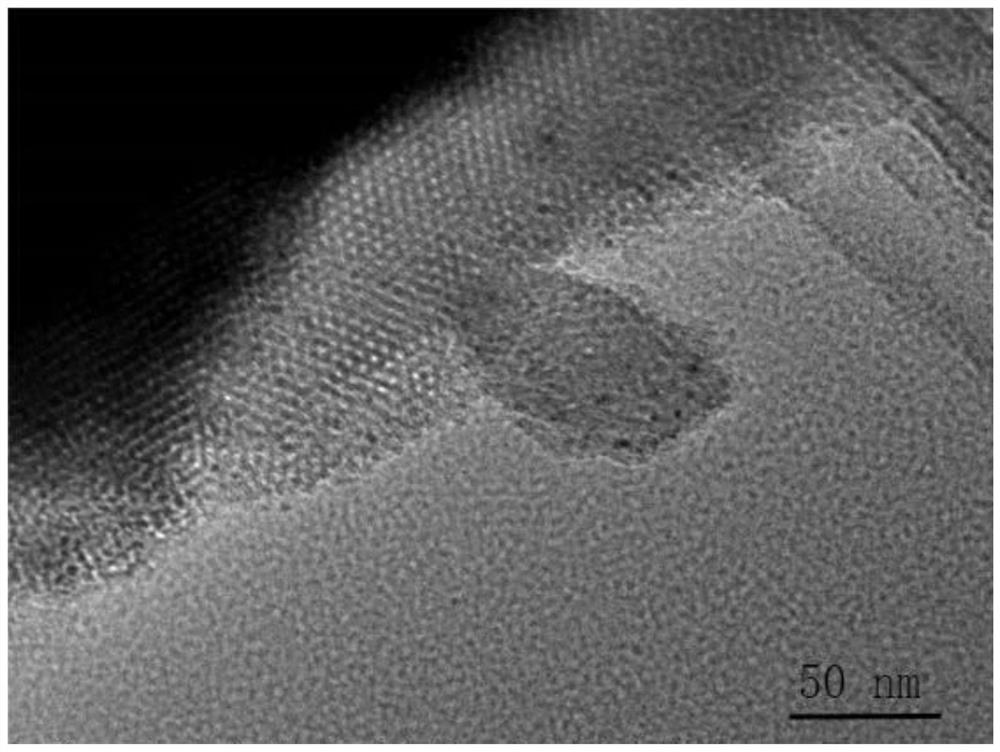

Image

Examples

Embodiment 1

[0054] A kind of platinum catalyst, its preparation method comprises the steps:

[0055] 1) Slowly add 1,2-bis(trimethoxysilyl)ethane (BTME) dropwise to octadecyltrimethylammonium chloride (ODTMACl), sodium hydroxide (NaOH) and water (H 2 O) obtain mixed solution, wherein, the mol ratio of various raw materials is BTME:ODTMA:NaOH:H 2 O=1:0.12:1:231;

[0056] 2) After the mixed solution was stirred at room temperature for 24 hours, it was filtered, washed and dried to obtain a white solid; 1g of the white solid was added to 150mL of ethanol solution containing 3.8g of HCl solution (36wt.%), and the magnetic stirring was continued at 50°C After 6 hours, wash with ethanol and deionized water, filter, remove the surfactant, and finally dry at 80°C for 6 hours to obtain the HMM-1 carrier (referred to as HMM-1);

[0057] 3) Weigh 1g of HMM-1 carrier into a 100mL eggplant-shaped bottle, add the precursor salt H 2 PtCl 6 ·6H 2 O (the total mass of precious metals accounts for 1%,...

Embodiment 2

[0061] A kind of platinum catalyst, its preparation method comprises the steps:

[0062] 1) Weigh 1g of HMM-1 carrier into a 100mL eggplant-shaped bottle, add precursor salt H 2 PtCl 6 ·6H 2 O (the total mass of precious metals is 1%, that is, the amount of precious metals is 1% of the mass of the HMM-1 carrier) and 50mL of deionized water, at a temperature of 25°C, set the ultrasonic power to 30W, and ultrasonically for 1h to obtain a platinum precursor suspension;

[0063] 2) The platinum precursor suspension was subjected to rotary evaporation, and then vacuum-dried at 50° C. for 12 hours to obtain a powder containing the precursor;

[0064] 3) Place the powder containing the precursor in 5% H 2 and N 2 Reduction at 200°C for 2 hours under the condition of mixed gas to obtain a platinum catalyst (denoted as Pt / HMM-1-2).

Embodiment 3

[0066] A preparation method for a platinum catalyst, comprising the steps of:

[0067] 1) Weigh 1g of HMM-1 carrier into a 100mL eggplant-shaped bottle, add precursor salt H 2 PtCl 6 ·6H 2 O (the total mass of precious metals is 1%, that is, the amount of precious metals is 1% of the mass of the HMM-1 carrier) and 50mL of deionized water. At a temperature of 25°C, set the ultrasonic power to 40W and ultrasonically for 1h to obtain a platinum precursor. suspension;

[0068] 2) The platinum precursor suspension was subjected to rotary evaporation, and then vacuum-dried at 50° C. for 12 hours to obtain a powder containing the precursor;

[0069] 3) Place the powder containing the precursor in 5% H 2 and N 2 Reduction at 200°C for 2 hours under the condition of mixed gas to obtain a platinum catalyst (denoted as Pt / HMM-1-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com