Preparation method and application of hydrogenation catalyst

A hydrogenation catalyst and oxidant technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as waste, resource utilization of NOx gas and dust, and reduce consumption and nitric acid. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A first aspect of the present invention provides a method for preparing a hydrogenation catalyst, the method comprising the following steps:

[0041] 1) The step of kneading and molding the carrier raw material and the kneading solution;

[0042] 2) Carrying out the step of first roasting the product obtained in step 1) to obtain a hydrogenation catalyst carrier;

[0043] 3) a step of first contacting the hydrogenation catalyst carrier obtained in step 2) with the metal salt solution;

[0044] 4) performing a second roasting on the product obtained in step 3) to obtain a hydrogenation catalyst;

[0045] Wherein, the method also includes: recovering and treating the roasting tail gas produced in step 2) and / or step 4), obtaining dust-containing water and recycled nitric acid, and using the dust-containing water and recycled nitric acid in the preparation step 1) The step of kneading the liquid in the method; the treatment includes: performing water dedusting treatment ...

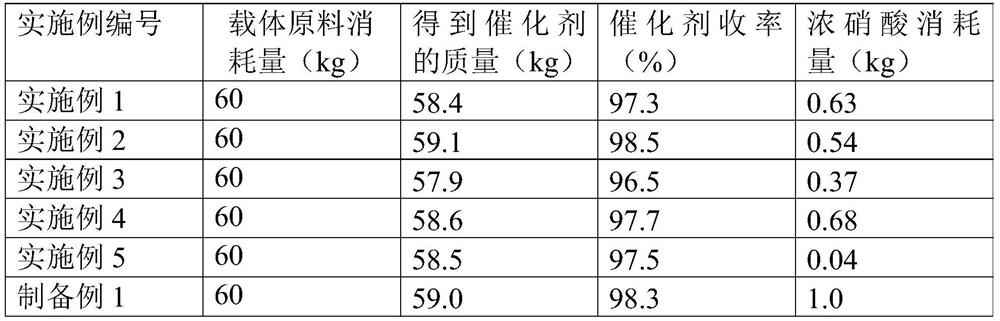

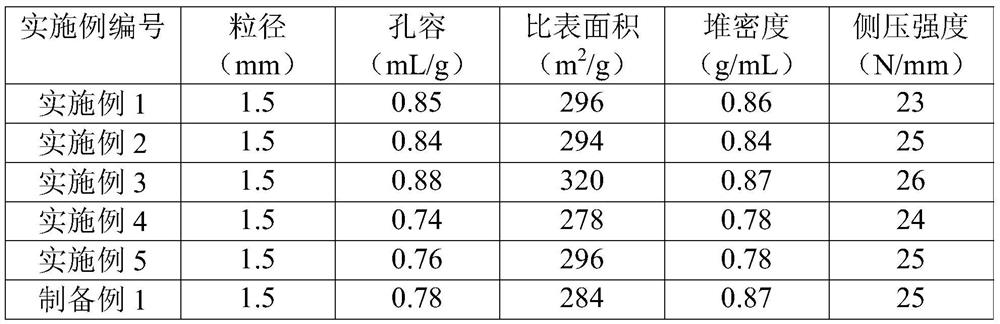

Embodiment

[0083] The present invention will be described in detail through examples below, but the present invention is not limited to the following examples.

[0084] In the following examples, the macroporous alumina was purchased from Chalco Shandong Co., Ltd., and the wet dust collector was manufactured by Jiangsu Erhuan Environmental Protection Technology Co., Ltd., model EHVQL 700. The environmental protection device is manufactured by Sinopec Energy Conservation and Environmental Protection Technology Co., Ltd. The concentration of concentrated nitric acid was 65% by mass.

preparation example 1

[0086] (1) Weigh 60 kg of macroporous alumina as a carrier material and put it into a kneader, mix concentrated nitric acid and purified water at a mass ratio of 0.015:1 to obtain a kneading liquid. Add 55kg of kneading liquid into the kneader, knead at 30°C for 20 minutes, extrude the kneaded material with an extruder, and dry the strips at a temperature of 110°C for 45 minutes to obtain dry strips.

[0087] (2) Put the dry bar obtained in step (1) into a converter, and roast at 750° C. for 3.5 hours to obtain a catalyst carrier. Pass the exhaust gas of the converter into the wet dust collector equipped with a cyclone (wind pressure is 0.4MPa, the volume ratio of exhaust gas to water is 200:1), and obtain dust-containing water and dust-removed exhaust gas. The volume ratio of exhaust gas to hydrogen peroxide is 60:1 The dedusting tail gas is passed into a plate tower with a concentration of 15 mass % hydrogen peroxide having 4 plates and a tower diameter of 50 cm, and counter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com