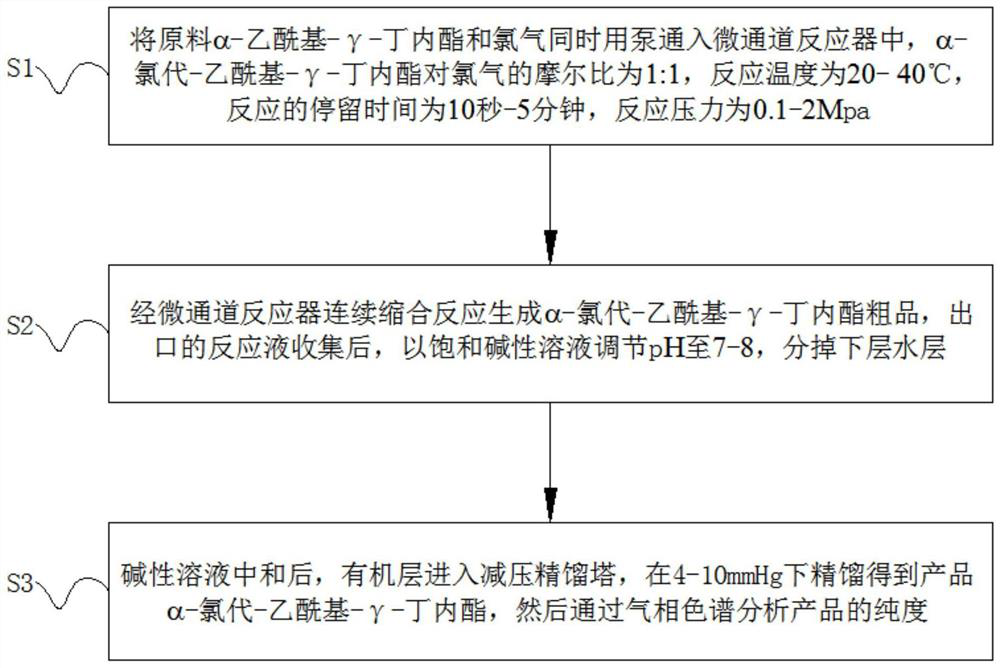

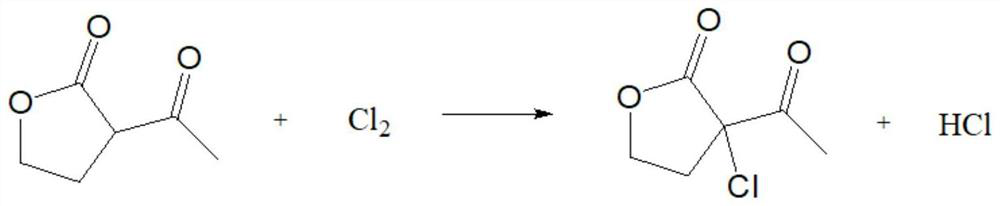

Alpha-chloro-acetyl-gamma-butyrolactone continuous flow microchannel reaction generation process

A technology of channel reaction and generation process, applied in chemical/physical/physical chemical reactors, organic chemistry, chemical/physical/physical chemical processes, etc., can solve problems such as long reaction time, and achieve product purity and quality improvement and stability production, avoiding overused effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Feed the raw material α-acetyl-γ-butyrolactone at 100g / h, chlorine gas 55.3g / h, (α-acetyl-γ-butyrolactone: chlorine gas=1:1) into the microchannel reactor at the same time , react at 20°C, 0.5Mpa, and a residence time of 90 seconds. After collecting the reaction liquid at the outlet, adjust the pH to 7-8 with saturated sodium bicarbonate solution. The lower water layer was separated, and the organic layer entered a rectification under vacuum tower with an operating pressure of 2 mmHg to obtain the product α-chloro-acetyl-γ-butyrolactone with a purity of 99.3% (gas chromatography analysis) and a total yield of 95.4%.

Embodiment 2

[0033] Feed the raw material α-acetyl-γ-butyrolactone at 100g / h, chlorine gas 55.3g / h, (α-acetyl-γ-butyrolactone: chlorine gas=1:1) into the microchannel reactor at the same time , react at 30°C, 0.5Mpa, and a residence time of 75 seconds. After collecting the reaction liquid at the outlet, adjust the pH to 7-8 with saturated sodium bicarbonate solution. The lower water layer was separated, and the organic layer entered a rectification under vacuum tower with an operating pressure of 2 mmHg to obtain the product α-chloro-acetyl-γ-butyrolactone with a purity of 99.1% (gas chromatography analysis) and a total yield of 94.2%.

Embodiment 3

[0035] Feed the raw material α-acetyl-γ-butyrolactone at 100g / h, chlorine gas 55.3g / h, (α-acetyl-γ-butyrolactone: chlorine gas=1:1) into the microchannel reactor at the same time , react at 20°C, 0.5Mpa, and a residence time of 40 seconds. After collecting the reaction liquid at the outlet, adjust the pH to 7-8 with 10% sodium hydroxide solution. The lower water layer was separated, and the organic layer entered a rectification under vacuum tower with an operating pressure of 2 mmHg to obtain the product α-chloro-acetyl-γ-butyrolactone with a purity of 99.1% (gas chromatography analysis) and a total yield of 93.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com