Self-curing resin as well as preparation method and application thereof

A self-curing, resin technology, used in chemical instruments and methods, applications, other household appliances, etc., can solve problems such as difficulty in ensuring uniform dispersion of curing agents, uneven curing crosslinking density of thermosetting resins, and differences in mechanical properties and thermal properties. , to achieve excellent thermal and mechanical properties, avoid excessive cross-linking, and achieve stable and controllable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention also provides a preparation method of the self curing resin as described above, comprising the following steps:

[0027] S1, providing a first thermosetting resin with an epoxy value of 0.20-0.60;

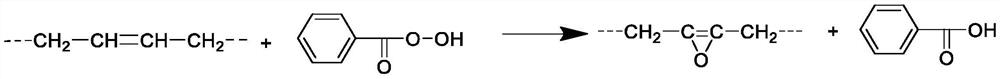

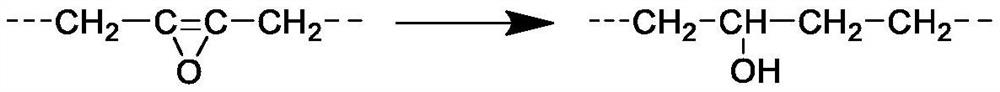

[0028]S2, the first thermosetting resin is subjected to ring opening reaction to obtain an intermediate. The molecular chain of the intermediate includes hydroxyl and epoxy group, and the molar ratio of hydroxyl to epoxy group is 1:2-1:20; as well as

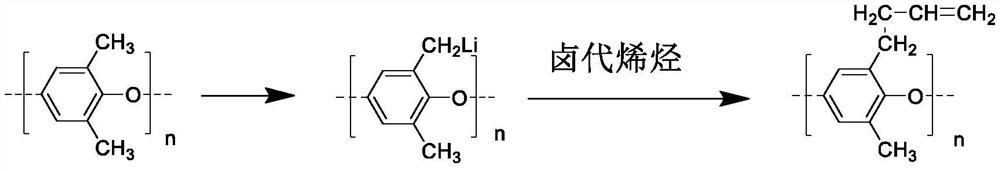

[0029] S3, the intermediate is substituted with haloalkyne to obtain self curing resin.

[0030] In the preparation method of self curing resin, the first thermosetting resin with specific epoxy value is used as raw material, and part of the epoxy group in the first thermosetting resin is opened and replaced by Haloalkynes, so that the unsaturation of the self curing resin is increased by 10% ~ 70% compared with that of the first thermosetting resin, and the simple preparation of self curing resin is realized.

[003...

Embodiment 1

[0070] Provide epoxy resin with epoxy value of 0.43.

[0071] The ring opening reaction of epoxy resin is carried out in the presence of ring opening reaction catalyst dodecyl dimethyl amine and ring opening reaction assistant formic acid. According to the molar ratio of cycloxy, formic acid and dodecyl dimethyl amine in epoxy resin is 25:5:1, the intermediate is obtained. The molecular chain of the intermediate includes hydroxyl and epoxy group, and the molar ratio of hydroxyl to epoxy group is 1:4.

[0072] Add the intermediate into butanol, stir under the water bath condition of 50 ℃ to mix evenly, slowly drop 0.8mol / l potassium hydroxide solution, and slowly drop 3-bromopropyne under the water bath condition of 65 ℃, the molar ratio of 3-bromopropyne to hydroxyl group in the intermediate is 1:1. After reacting at 65 ℃ for 4h, wash in batches with hot deionized water and ethanol to remove the salt formed by the reaction, and obtain Brown resin after liquid separation and spin e...

Embodiment 2

[0077] Example 2 is carried out with reference to example 1. The difference is that the epoxy value of epoxy resin is 0.20; The molecular chain of the intermediate includes hydroxyl group and epoxy group, and the molar ratio of hydroxyl group to epoxy group is 1:4; The molecular chain of self curing resin includes alkynyl group and epoxy group. The molar ratio of alkynyl group to epoxy group is 1:4. The mass fraction of epoxy group in self curing resin is 6.9%, and the mass fraction of alkynyl group in self curing resin is 1.72%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com