Fischer-Tropsch synthetic oil processing technology

A Fischer-Tropsch synthetic oil and processing technology, which can be used in hydrotreating technology, petroleum industry, processing hydrocarbon oil, etc., and can solve problems such as poor diesel selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

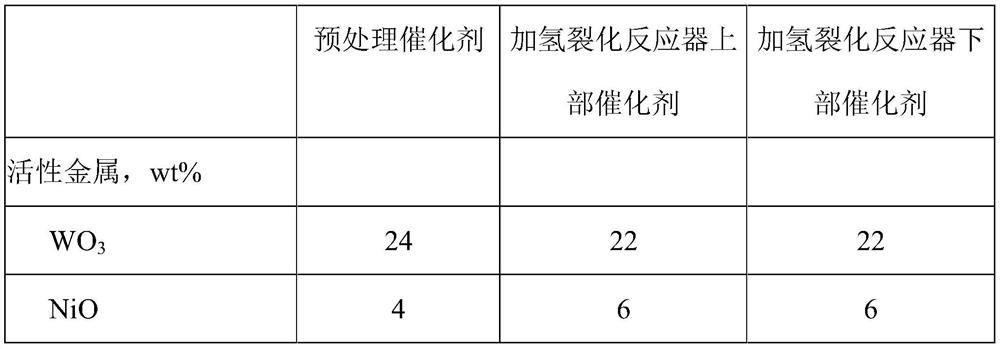

[0030] Table 1 is the properties of the raw oil, Table 2 is the composition of the catalyst, and Table 3 is the operating conditions and reaction effects.

[0031] Table 1

[0032] Density, g / cm 3

0.8042 Distillation range, ℃ IBP 165 10% 308 30% 362 50% 462 70% 552 90% 575 FBP 705 Olefin content, wt% 6% Oxygen content, wt% 1%

[0033] Table 2

[0034]

[0035]

[0036] table 3

[0037]

Embodiment 2

[0039] Table 4 shows the properties of the raw oil, Table 5 shows the composition of the catalyst, and Table 6 shows the operating conditions and reaction effects.

[0040] Table 4

[0041]

[0042]

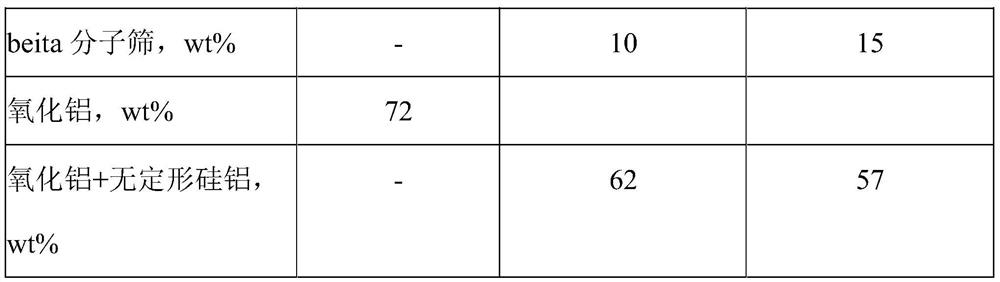

[0043] Table 5 Example 2 Catalyst

[0044]

[0045] Table 6

[0046]

Embodiment 3

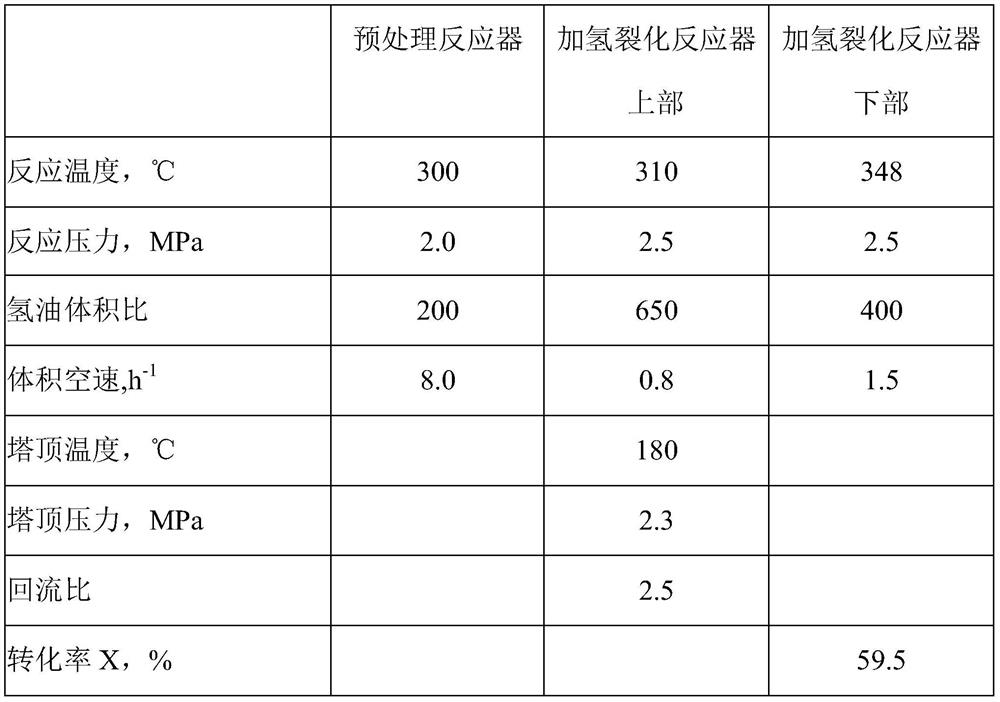

[0048] Table 7 shows the properties of the raw oil, Table 8 shows the composition of the catalyst, and Table 9 shows the operating conditions and reaction effects.

[0049] Table 7

[0050]

[0051]

[0052] Table 8

[0053]

[0054] Table 9

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com