A kind of preparation of hydrogenation catalyst and hydrogenation catalyst and application

A hydrogenation catalyst, catalyst technology, applied in catalyst activation/preparation, hydrogenation to hydrocarbons, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of difficulty in ensuring stability, catalyst activity, selectivity, stability problems such as sexual restriction and stay, to achieve good industrial application prospects, guarantee selectivity and activity stability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

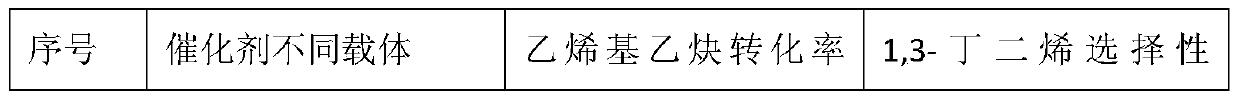

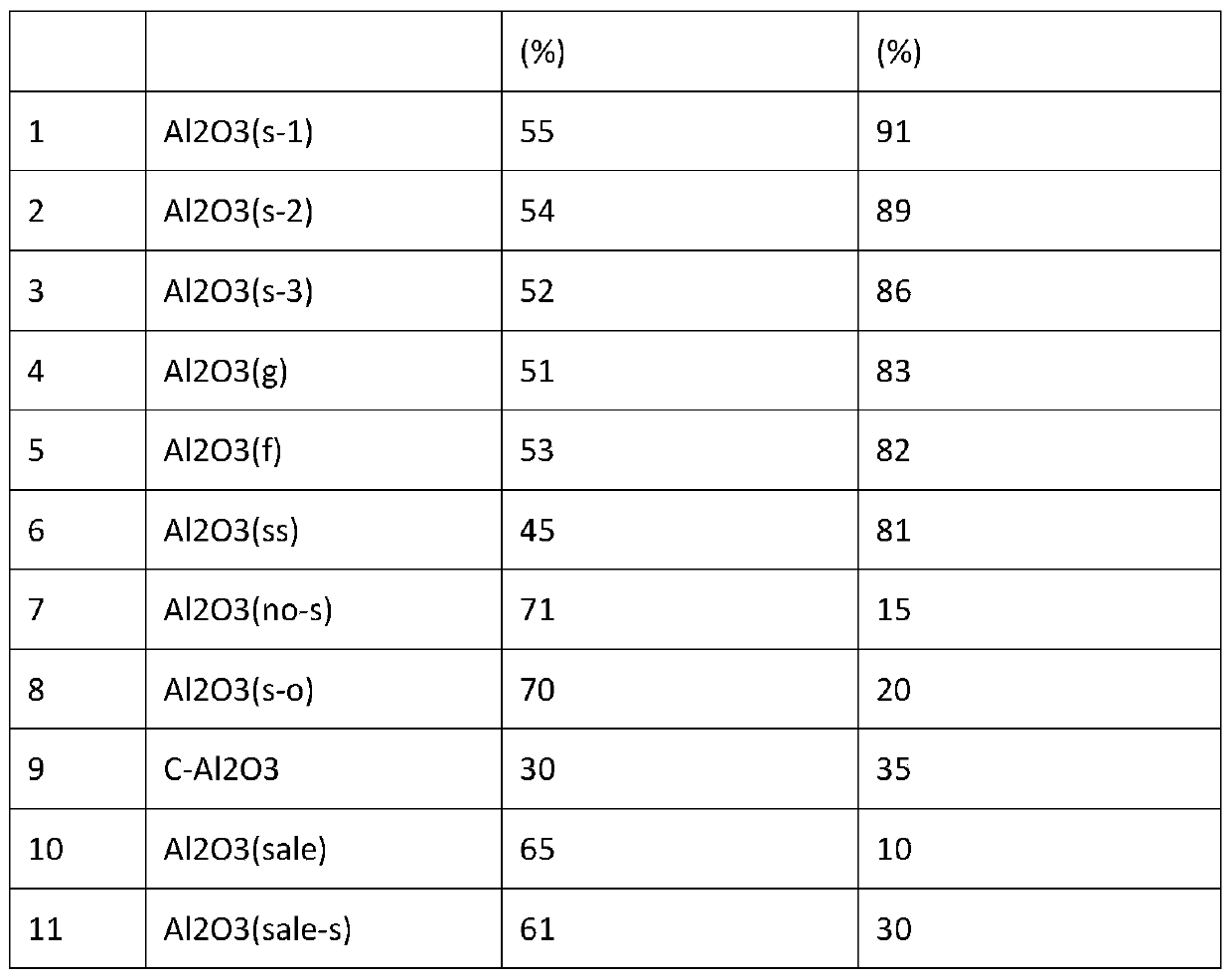

Embodiment 1

[0023] Preparation of alumina carrier: Take 15g boehmite powder (Al2O3 dry basis content is 80%), disperse it in 150ml water, heat up to 80°C, add 2mol / L dilute HNO3 dropwise, adjust the pH value to 1.5-2.5, and carry out degumming , the boehmite sol was obtained after stirring for 6 hours. Then, after adding 2.4g of sucrose and stirring to dissolve, aged at room temperature for 6h, then transferred to an oven and dried at 90°C for 12 hours to obtain a solid sample labeled as S-Al2O3, and then transferred to a muffle furnace and slowly raised the temperature to 800°C under the protection of nitrogen. ℃ for 3 hours, and the heating rate is 0.5 ℃ / min to obtain the carbon-alumina composite carrier C-Al2O3. The C-Al2O3 sample obtained by roasting in nitrogen was cooled to below 200°C in a nitrogen atmosphere, then air was introduced, and then roasted again. The roasting temperature was 650°C, the roasting time was 2 hours, and the heating rate was 1°C / min. Thus, the required alum...

Embodiment 2

[0025] Preparation of alumina carrier: The experimental conditions are the same as in Example 1, except that sucrose is replaced by glucose, fructose, and soluble starch to obtain alumina carriers, which are respectively marked as Al2O3(g), Al2O3(f), and Al2O3(ss).

Embodiment 3

[0027] Preparation of alumina carrier: the experimental conditions are the same as in Example 1, except that the amount of sucrose added is 1.0g and 3.5g respectively, and the obtained alumina carrier is marked as Al2O3(s-2), Al2O3(s-3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com