Large-temperature-difference high-temperature heat pump hot water unit driven by engine

An engine-driven, high-temperature heat pump technology, used in refrigerators, compressors, refrigeration components, etc., to achieve the effects of high outlet water temperature, high work efficiency, and reasonable unit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

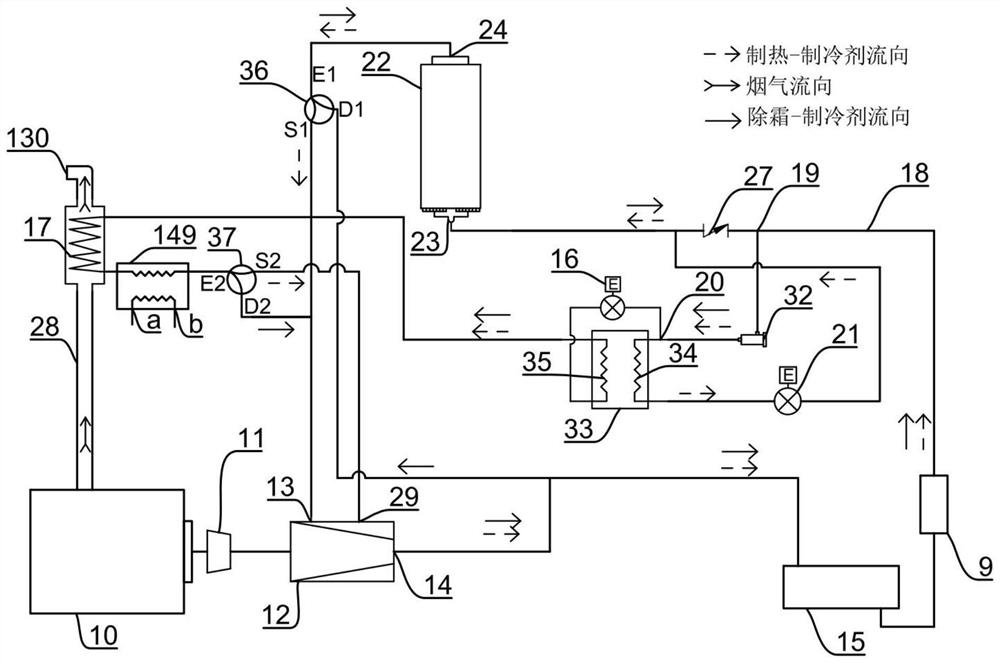

Method used

Image

Examples

Embodiment 2

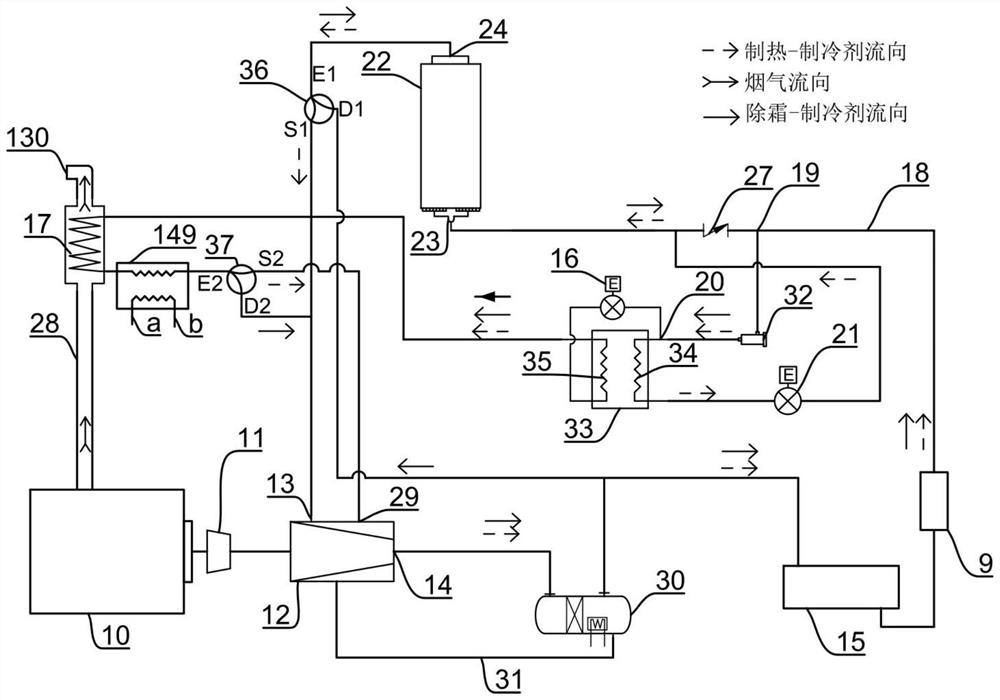

[0067] The work process of embodiment two is basically the same as embodiment one, and the difference is:

[0068] Such as image 3 As shown, no matter in the heating mode or the defrosting mode, the refrigerant gas discharged from the exhaust port 14 of the compressor 12 needs to enter the oil separator 30 through the oil refrigerant inlet, and the oil separator 30 will lubricate the refrigerant gas After the oil is separated, the separated lubricating oil returns to the compressor 12 through the lubricating oil circuit 31 .

[0069] Regardless of the heating mode or the defrosting mode, the refrigerant liquid must pass through the drying filter 32 to dry. The heating mode enters the flue gas refrigerant heat exchanger 17 and the cooling water refrigerant heat exchanger 149 through the first throttle valve 16, and enters the second heat exchanger 22 through the second throttle valve 21; The first throttle valve 16 enters the flue gas refrigerant heat exchanger 17 and the co...

Embodiment 3

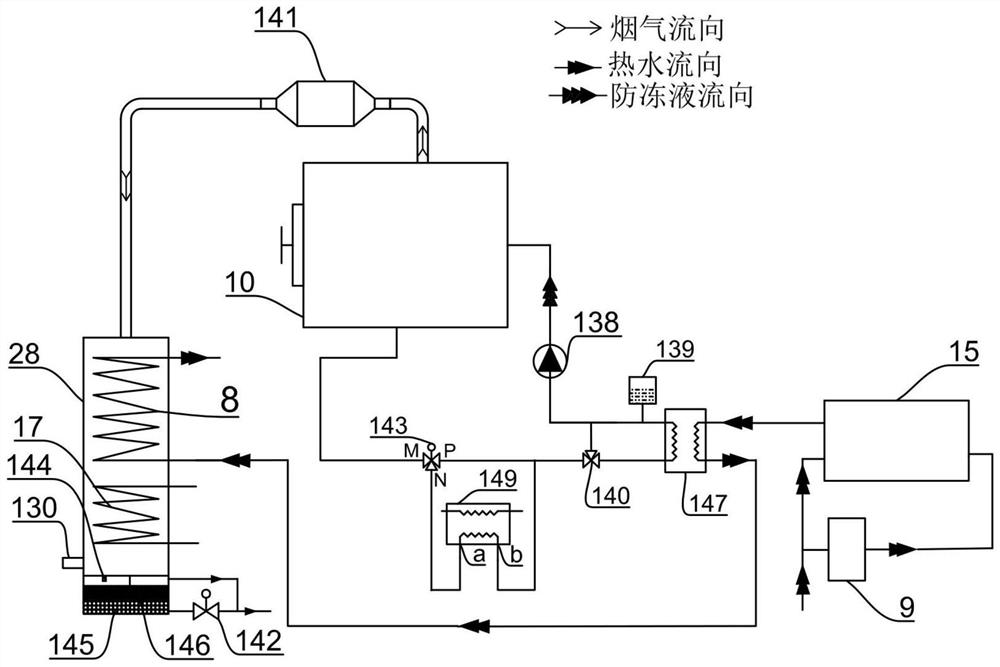

[0071] Figure 4 It is a schematic diagram of the connection and flow diagram of the peripheral parts of the engine-driven large-temperature-difference high-temperature heat pump hot water unit in Embodiment 3 of the present invention.

[0072] Such as Figure 4 As shown, Embodiment 3 provides an engine-driven engine-driven large temperature difference high-temperature heat pump water heater unit. The engine-driven large temperature difference high-temperature heat pump water heater unit differs from Embodiment 1 only in that: The cooling water heat exchanger 8 is arranged between the cylinder liner of the engine 10 and the cooling water inlet of the radiator 147. In this embodiment, the flue gas cooling water heat exchanger 8 is arranged between the cylinder liner of the engine 10 and the cooling water three-way valve 143 . Therefore, the cooling water from the cylinder liner of the engine 10 will first flow through the flue gas cooling water heat exchanger 8 and then enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com