Lithium-sulfur battery positive electrode composite material based on biomass carbon source as well as preparation method and application of lithium-sulfur battery positive electrode composite material

A biomass carbon source and composite material technology, applied in the field of lithium-sulfur battery positive electrode, can solve the problems of reducing battery coulombic efficiency, corrosion of metal lithium negative electrode, and increasing electrolyte viscosity, so as to improve the capture effect, enhance electron exchange, and improve catalysis. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0051] 1. A lithium-sulfur battery cathode composite material based on a biomass carbon source and its preparation method and application, comprising the following steps:

[0052] (1) Peel the dried corn stalks and cut them into small pieces (about 3 cm) of equal length, wash them with deionized water several times, and then put them in an air-blast drying oven at 80°C to dry overnight.

[0053] (2) Add 5mM FeCl to a beaker containing 200mL of deionized water 3 ·6H 2 O and 5mM (NH 4 ) 2 HPO 4 , stirred for 1 h to form a light yellow cloudy liquid. After immersing the dried corn stalks for 12 hours, take them out and put them in an air blast drying oven at 80° C. to dry overnight.

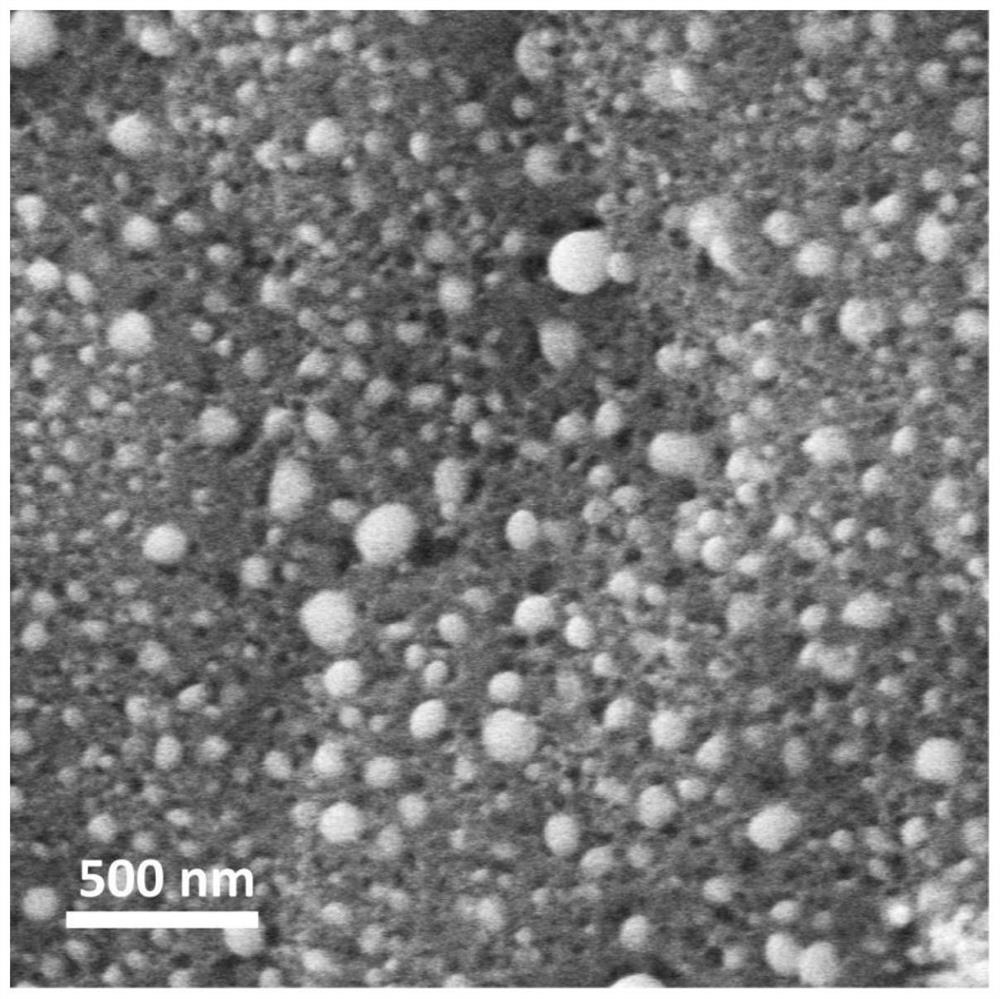

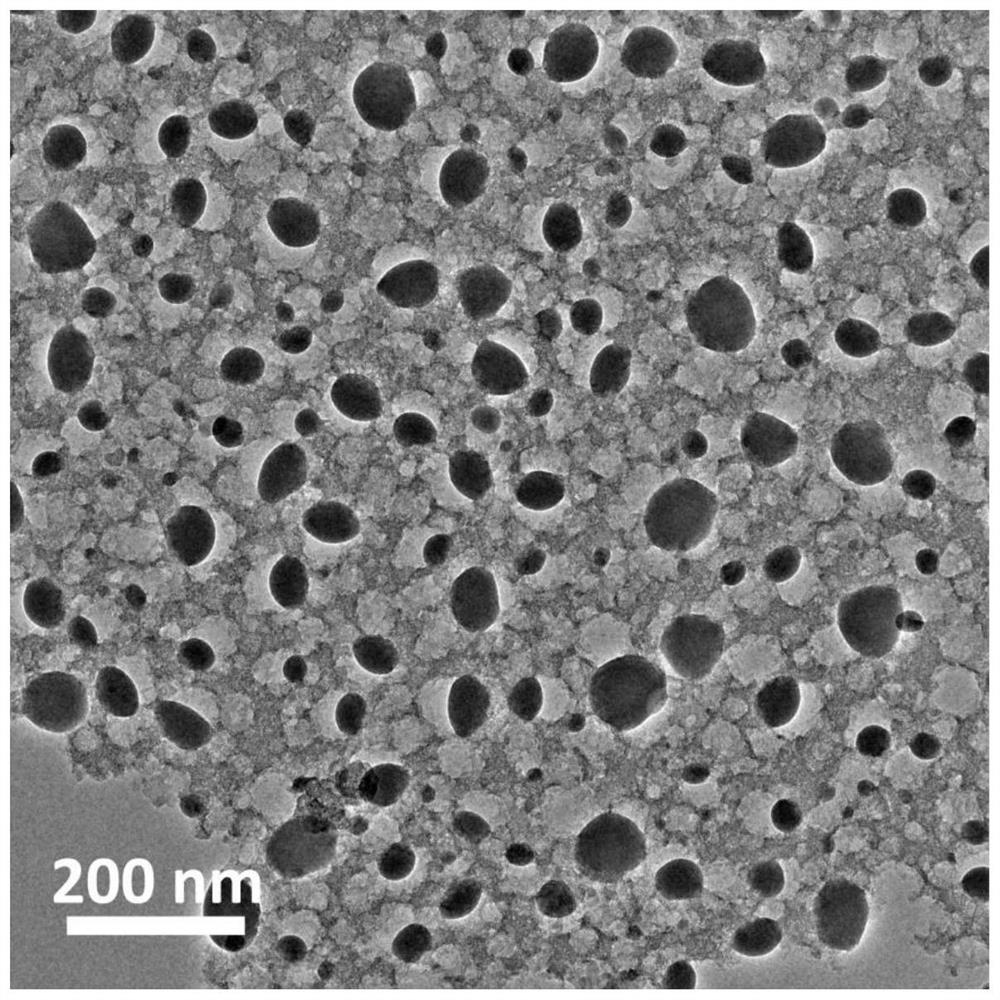

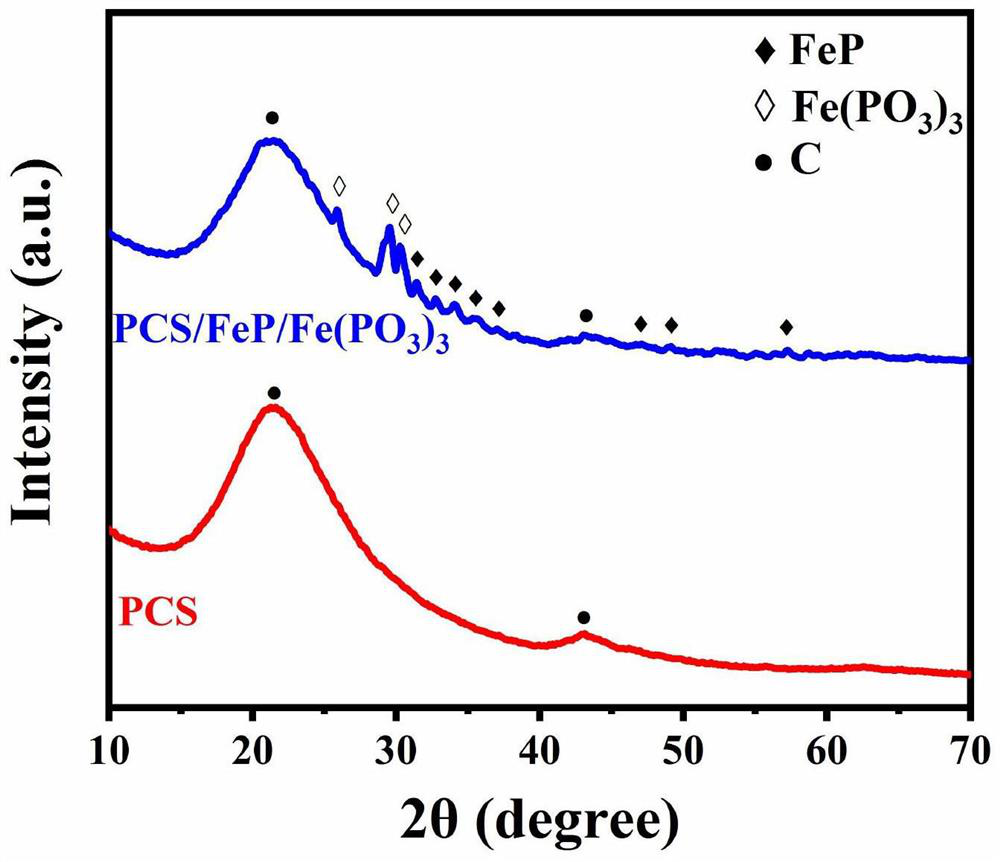

[0054] (3) Put the dried sample into a tube furnace, under the protection of Ar, at 2°C min -1 The heating rate was increased to 900 °C, and kept for 2 hours, then cooled to room temperature with the furnace, and the porous carbon sheet / iron phosphide / iron metaphosphate composite material (PCS...

no. 2 example

[0063] 1. A lithium-sulfur battery cathode composite material based on a biomass carbon source and its preparation method and application, comprising the following steps:

[0064] (1) Pour freshly squeezed sugarcane juice and deionized water into a large beaker at a volume ratio of 1:5, stir evenly, and then filter to remove sugarcane residue. Take 600 mL of the homogeneous mixture and add it to a 1 L Teflon-lined reaction kettle. The reaction kettle was transferred to a blast drying oven at 160° C., kept warm for 6 hours, and then cooled to room temperature to obtain a brownish-red liquid. The brownish-red suspension was centrifuged, and the separated sample was washed three times with deionized water and alcohol, respectively, and dried overnight at 60° C. to obtain a precursor of biomass carbon microspheres.

[0065] (2) Add 0.6g carbon microsphere precursor to the prepared 30mL 2M Co(NO 3 ) 3 In the solution (the solvent is deionized water and alcohol with a volume rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com