Laser heat dissipation material with similar optical fiber waveguide structure

A fiber optic waveguide and heat dissipation material technology, applied in the laser field, can solve problems such as poor thermal conductivity, and achieve the effects of small contact area, good heat dissipation operation, and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

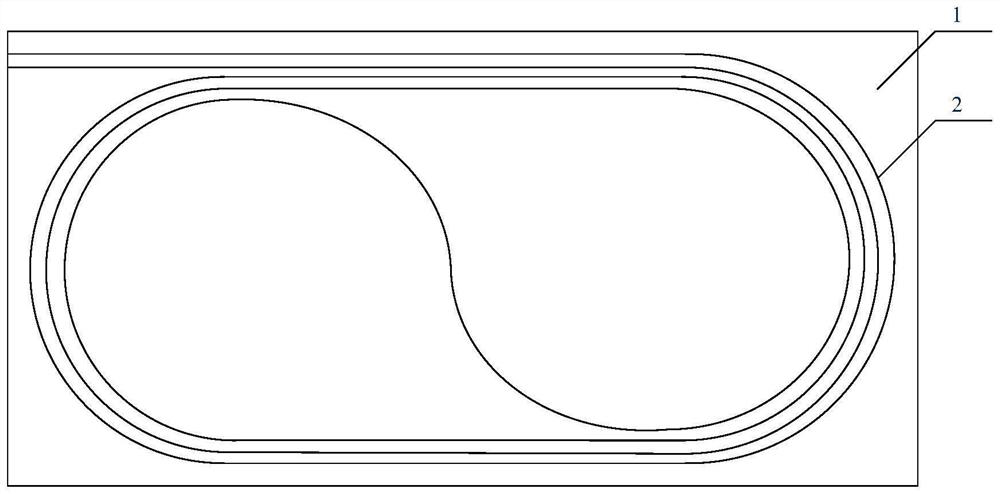

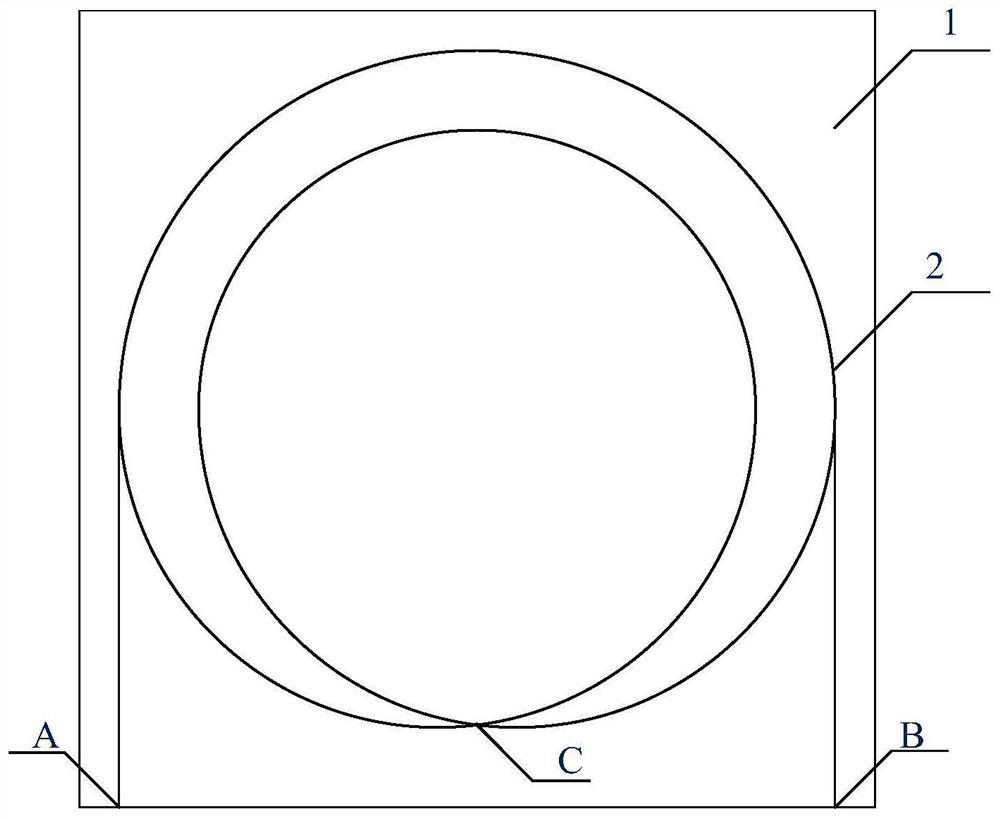

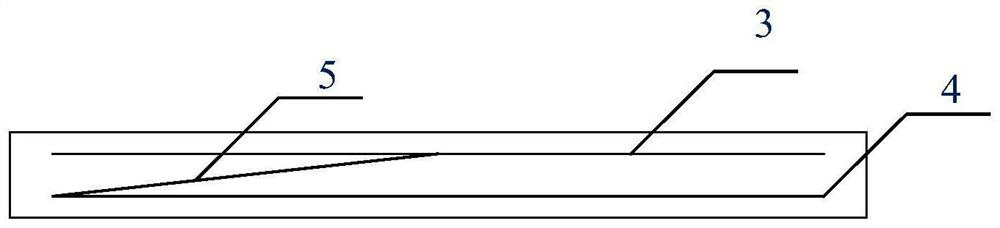

[0027] A laser heat dissipation material 1 with a fiber-optic waveguide-like structure, in which a fiber-optic waveguide-like structure 2 is formed inside by laser engraving and processing laser crystals or laser transparent ceramic substrates. The laser crystal or the laser transparent ceramic matrix is a laser crystal or laser transparent ceramic matrix doped with rare earth ions, and is transparent to the laser band, and has a thermal conductivity greater than 1.38W / m·K. The fiber-like waveguide structure 2 is in the shape of a single-layer or multi-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com