A kind of selenium disulfide foam agent for shampooing and preparation method thereof

A technology of selenium disulfide and foaming agent, applied in cosmetic preparations, cosmetic preparations, preparations for skin care, etc., can solve the problems of incomplete absorption, easy discoloration, hair adhesion and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

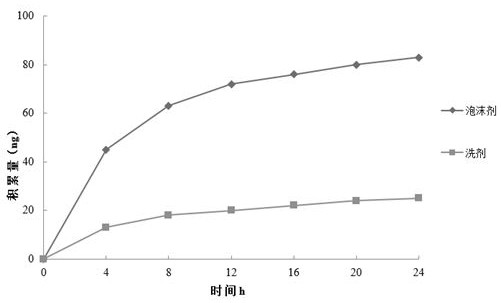

Image

Examples

preparation example 1

[0042] Mix selenium disulfide dry powder with a D90 of about 130 μm, water, and glycerin at a mass ratio of 1:3:1, and pulverize it in an ultrafine pulverizer for 30 minutes to finally obtain a selenium disulfide powder with a D90 of about 22 μm.

preparation example 2

[0044] Weigh each component according to proportioning, prepare selenium disulfide foam according to the following steps:

[0045] S1. Put 50% of the total amount of deionized water in the reaction tank of a high-shear mixing emulsifier, heat it to 60°C, add foam support components, foaming agents, and chelating agents under stirring, and stir to dissolve all ingredients. forming a first mixture;

[0046] S2. Dissolving the antioxidant in alcohol, slowly adding the alcohol solution of 10wt% antioxidant, penetration enhancer, phosphatidylserine, and conditioning agent into the first mixture, stirring to dissolve all the ingredients, as the second mixture;

[0047] S3, adding the selenium disulfide micropowder into the second mixture, fully stirring evenly;

[0048] S4. Add an appropriate amount of essence and pH regulator lactic acid, make up deionized water, continue to stir and emulsify for 1 hour, and at the same time cool the temperature of the tank to room temperature to ...

Embodiment 1

[0050] The research of embodiment 1 antioxidant:

[0051] Prepare the selenium disulfide foam agent according to the method of Preparation Example 2, and the composition mass percentage formula of the foam agent is as shown in Table 1 below:

[0052] Table 1 Foam composition

[0053]

[0054] Comparing different types of antioxidants, it is found that the antioxidant effect of butylated hydroxytoluene (BHT) is better than that of vitamin E, and the color of the foam can be satisfied at a lower dosage. After testing, the comparison of different amounts of antioxidants shows that dibutyl hydroxytoluene (BHT) can achieve the color change of the sample in the range of 0.005~10%, and when the amount of dibutyl hydroxytoluene is less than 0.01%, the anti-oxidation cannot be achieved. Effect; more than 10% (0.1% w / w), may cause chronic poisoning, deformity, metabolic disorders and other risks to the human body, so the optimal dosage is 0.03~0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com