Magnetic Mxene microbial carrier material and preparation method thereof

A microbial carrier and magnetic technology, which is applied in the field of magnetic Mxene microbial carrier material and its preparation, can solve the problems of inability to achieve chemical modification or modification effect of iron ferric oxide, inability to achieve recyclability, inability to use oilfield wastewater, etc., to achieve capacity Reinforcement, good dispersibility, and increased activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of magnetic Mxene microorganism carrier material, comprises magnetic MXene material and lecithin, and described magnetic MXene material is made of Ti 3 AlC 2 and iron salt, the mass ratio of the magnetic MXene material to lecithin is 5:4.

[0033] Its preparation method comprises the following steps:

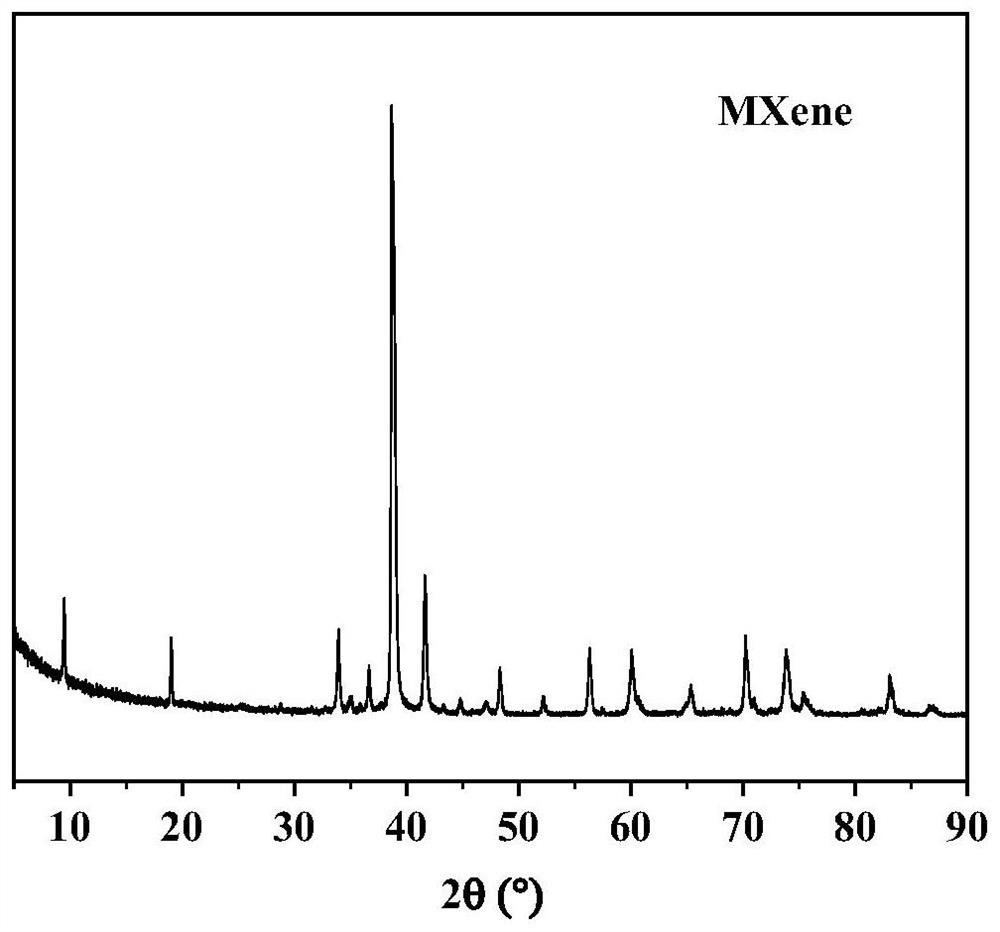

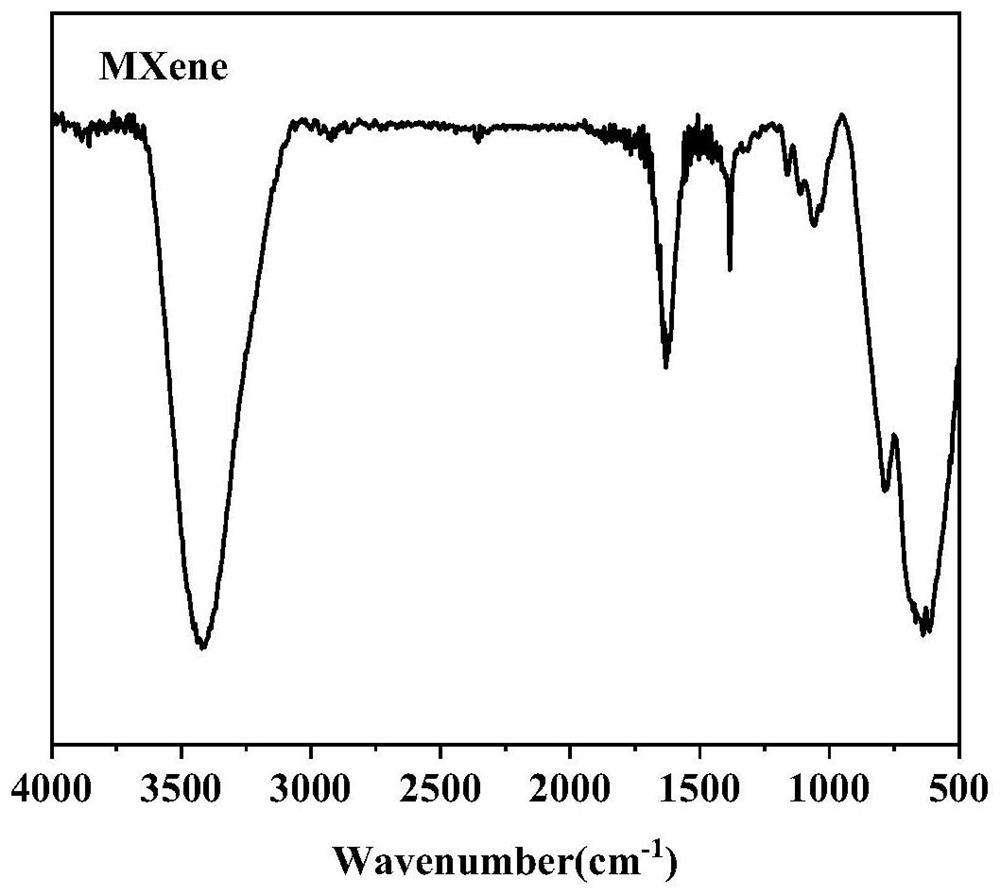

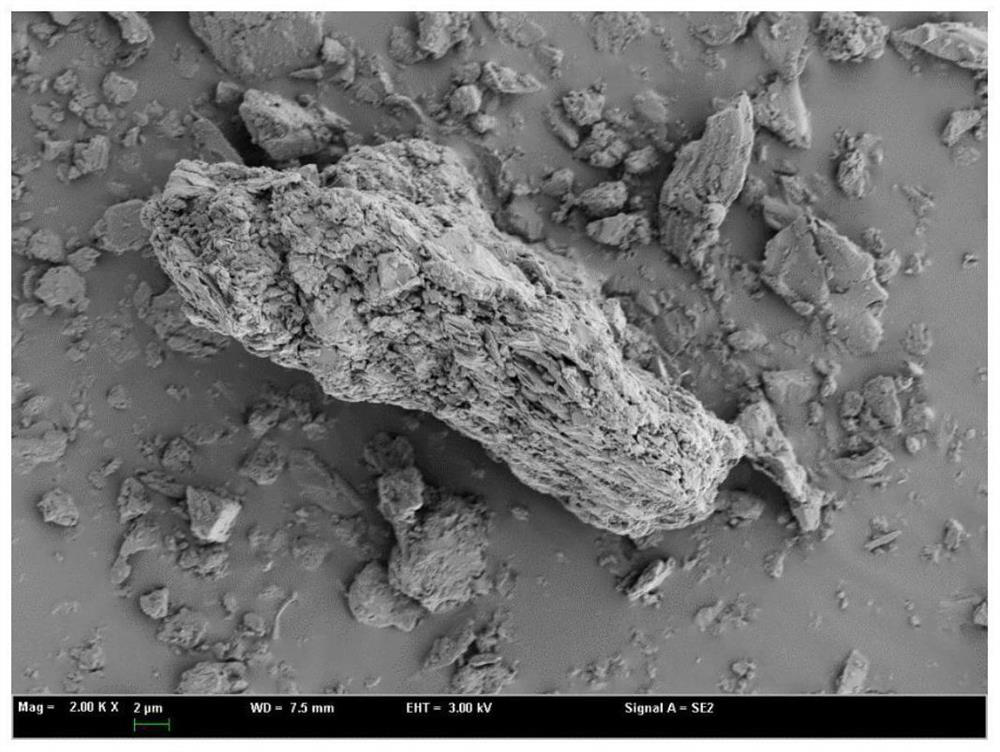

[0034] (1) Preparation of Mxene material

[0035] Take 3.5 g Ti 3 AlC 2 Put the powder (200 mesh) into a 100 mL plastic beaker, add an appropriate amount of 30% HF solution and stir at 30 °C for 24 h, centrifuge the above solution at 8000 rpm / min to remove residual impurities, and wash with deionized water and absolute ethanol The wet precipitate was alternately washed until the pH was 5, followed by stirring with dimethyl sulfoxide (DMSO) at 40 °C for 24 h. Centrifuge after the reaction, discard the supernatant, and wash the precipitate with deionized water several times to remove residual DMSO solution. Then, the precipitate was dispersed in deionized water...

Embodiment 2

[0041] A kind of magnetic Mxene microorganism carrier material, comprises magnetic MXene material and lecithin, and described magnetic MXene material is made of Ti 3 AlC 2 and iron salt, the mass ratio of the magnetic MXene material to lecithin is 5:4.

[0042] Its preparation method comprises the following steps:

[0043] (1) Preparation of Mxene material

[0044] Take 3.5 g Ti 3 AlC 2 Put the powder (200 mesh) into a 100 mL plastic beaker, add an appropriate amount of 30% HF solution and stir at 40 °C for 24 h, centrifuge the above solution at 8000 rpm / min to remove residual impurities, and wash it with deionized water and absolute ethanol The wet precipitate was alternately washed until the pH was 6, followed by stirring with dimethyl sulfoxide (DMSO) at 40 °C for 24 h. Centrifuge after the reaction, discard the supernatant, and wash the precipitate with deionized water several times to remove residual DMSO solution. Then, the precipitate was dispersed in deionized wa...

Embodiment 3

[0050] A kind of magnetic Mxene microorganism carrier material, comprises magnetic MXene material and lecithin, and described magnetic MXene material is made of Ti 3 AlC 2 and iron salt, the mass ratio of the magnetic MXene material to lecithin is 5:2.

[0051] Its preparation method comprises the following steps:

[0052] (1) Preparation of Mxene material

[0053] Take 3.5 g Ti 3 AlC 2 Put the powder (200 mesh) into a 100 mL plastic beaker, add an appropriate amount of 30% HF solution and stir at 40 °C for 12 h, centrifuge the above solution at 8000 rpm / min to remove residual impurities, and wash with deionized water and absolute ethanol The wet precipitate was alternately washed until the pH was 6, followed by stirring with dimethyl sulfoxide (DMSO) at 40 °C for 24 h. Centrifuge after the reaction, discard the supernatant, and wash the precipitate with deionized water several times to remove residual DMSO solution. Then, the mass ratio of the precipitate to water was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com