Glass strengthening method, glass substrate, and etching material for glass

A glass substrate and glass strengthening technology, applied in the field of glass substrates, etching materials for glass, and glass strengthening methods, can solve the problems of less improvement in mechanical properties and poor impact resistance of glass products, and achieve high appearance yield and improvement. Impact resistance, effect of suppressing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

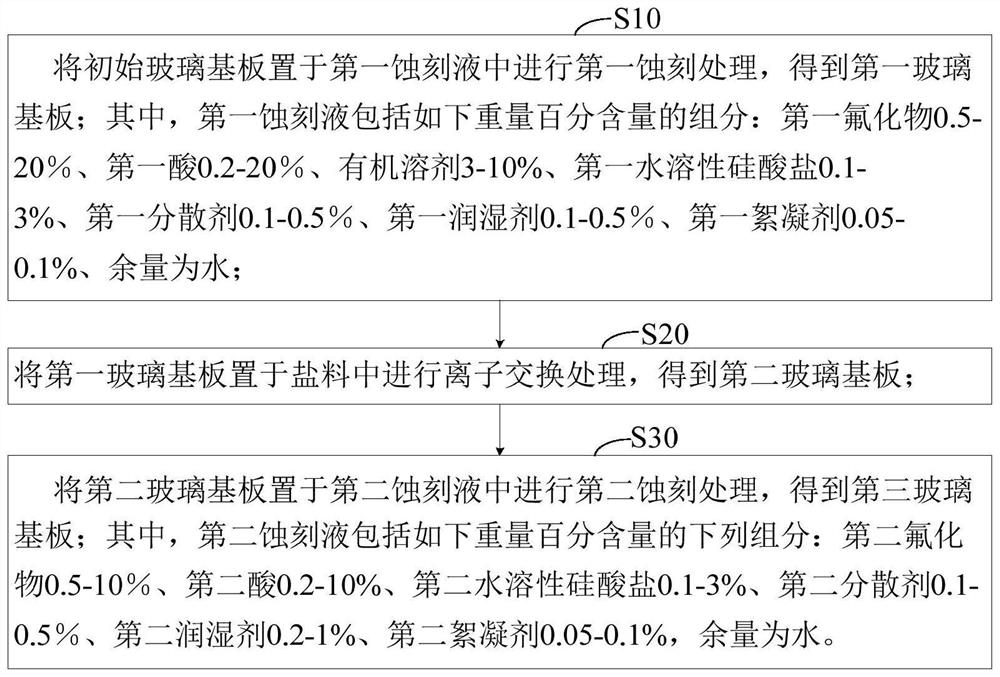

Method used

Image

Examples

Embodiment 1

[0070] This embodiment provides an etching material for glass, including: a first etching solution and a second etching solution;

[0071] Wherein, the first etching solution comprises the following components in weight percentage: 2% sodium fluoride, 4% sulfuric acid, 5% ethanol, 2% sodium silicate, 0.3% polyethylene glycol (polymerization degree 400), twelve 0.1% sodium alkylbenzene sulfonate, 0.1% diatomaceous earth, and the balance is deionized water;

[0072] The second etching solution comprises the following components in percentage by weight: sodium fluoride 0.5%, sulfuric acid 2%, sodium silicate 2%, polyethylene glycol (polymerization degree 400) 0.3%, sodium dodecylbenzenesulfonate 0.2%, diatomaceous earth 0.1%, and deionized water as the balance.

Embodiment 2

[0074] This embodiment provides an etching material for glass, including: a first etching solution and a second etching solution;

[0075] Wherein, the first etching solution comprises the following components in weight percentage: sodium fluoride 5%, sulfuric acid 4%, nitric acid 6%, ethanol 5%, sodium silicate 2%, polyethylene glycol (polymerization degree 400) 0.3 %, sodium dodecylbenzenesulfonate 0.2%, diatomaceous earth 0.1%, and the balance is deionized water;

[0076] The second etching solution comprises the following components in percentage by weight: sodium fluoride 2%, sulfuric acid 2%, nitric acid 3%, sodium silicate 2%, polyethylene glycol (polymerization degree 400) 0.3%, lauryl 0.3% sodium benzenesulfonate, 0.1% diatomaceous earth, and deionized water as the balance.

Embodiment 3

[0078] This embodiment provides an etching material for glass, including: a first etching solution and a second etching solution;

[0079] Wherein, the first etching solution includes the following components in weight percentage: 10% sodium fluoride, 10% sulfuric acid, 5% nitric acid, 5% ethanol, 2% sodium silicate, polyethylene glycol (polymerization degree 400) 0.3 %, sodium dodecylbenzenesulfonate 0.3%, diatomaceous earth 0.1%, and the balance is deionized water;

[0080] The second etching solution comprises the following components in percentage by weight: sodium fluoride 5%, sulfuric acid 5%, nitric acid 5%, sodium silicate 2%, polyethylene glycol (polymerization degree 400) 0.3%, lauryl 0.4% sodium benzenesulfonate, 0.1% diatomaceous earth, and deionized water as the balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com