Conductive aggregate preparation method and application thereof

An aggregate and fine aggregate technology, which is applied in the preparation of conductive aggregates and the application of smart cement-based composite materials, can solve the problems of carbon-based nanomaterials, such as difficulty in dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

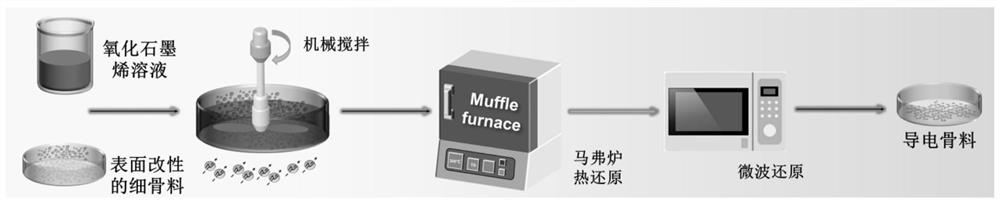

[0043] A method for preparing a self-inductive cement-based composite material modified by conductive aggregate and nano-interface in this embodiment, comprising:

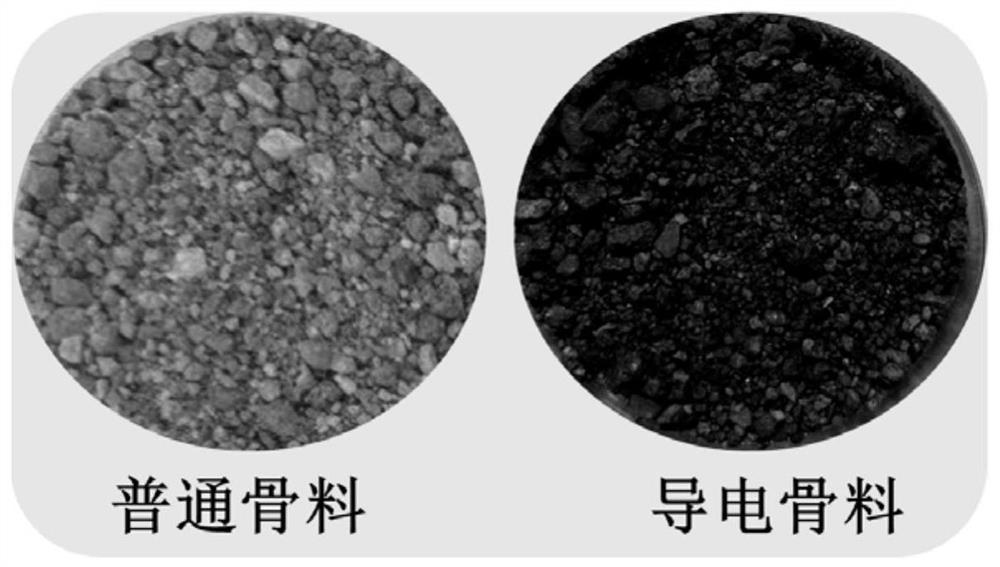

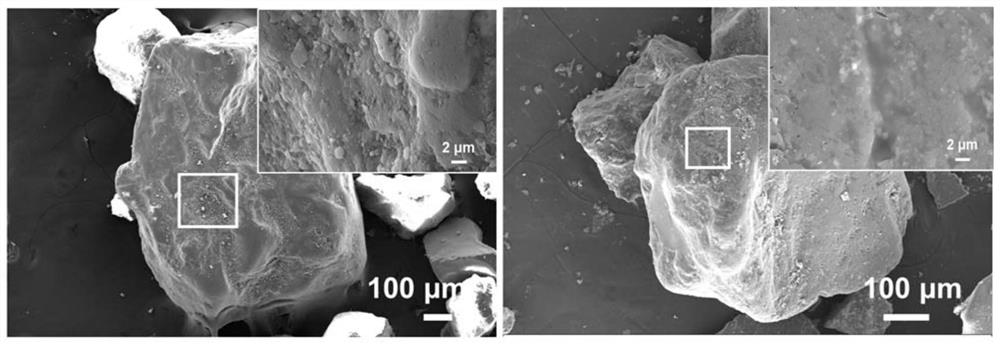

[0044] Put the GO solution and the surface-grafted calcium ion fine aggregate in a wide-mouthed aluminum basin at a volume ratio of 1:1.2, first manually stir for 3 minutes, and then place it under heating at 80°C, and continue stirring with a stirrer at a speed of 50 rpm for 2 hours. Make GO uniformly adsorbed on the surface of fine aggregate particles; then dry the fine aggregate with adsorbed graphene oxide in an oven at 60°C for 48 hours, and finally obtain fine aggregate with graphene oxide evenly wrapped on the surface;

[0045] Put the fine aggregate coated with graphene oxide on the surface in a muffle furnace for high temperature pre-reduction at 200°C for 1 hour; then, place the reduced graphene oxide fine aggregate obtained after high-temperature pre-reduction treatment in a microwave oven (power set to 8...

no. 2 example

[0054] The preparation method of a conductive aggregate and nano-interface modified self-induction cement-based composite material of this embodiment is different from that of Embodiment 1. In this embodiment, the volume ratio of the GO solution and the surface-grafted calcium ion to the fine aggregate is 1:1.5; the mixture was continuously stirred with a stirrer at a speed of 80rpm for 2h, so that GO was evenly adsorbed on the surface of fine aggregate particles; then the fine aggregate adsorbed graphene oxide was dried in an oven at 80°C for 48h, and finally the surface Fine aggregate that evenly wraps graphene oxide. The remaining steps are the same as in Embodiment 1.

no. 3 example

[0056] The preparation method of a conductive aggregate and nano-interface modified self-induction cement-based composite material of this embodiment is different from that of Embodiment 1. In this embodiment, the volume ratio of the GO solution and the surface-grafted calcium ion to the fine aggregate is It is 1:1.3. First, the mixture was hand-stirred for 2 minutes, then placed in a heating state at 90°C, and continuously stirred with a stirrer at a speed of 60 rpm for 1 hour, so that GO was evenly adsorbed on the surface of fine aggregate particles; The aggregates were dried in an oven at 60°C for 72 hours, and finally fine aggregates with graphene oxide uniformly coated on the surface were obtained. The remaining steps are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com