Ultrahigh wear-resistant BOPP (Biaxially-oriented Polypropylene) film and preparation method thereof

An ultra-high, ethylene technology, applied in the direction of chemical instruments and methods, flat products, and other household appliances, can solve the problems of easy aggregation of inorganic nano-scale substances, affecting the optical properties of the film, and defects in the appearance of the film, so as to maintain the design effect , enhance the desire to buy, the effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

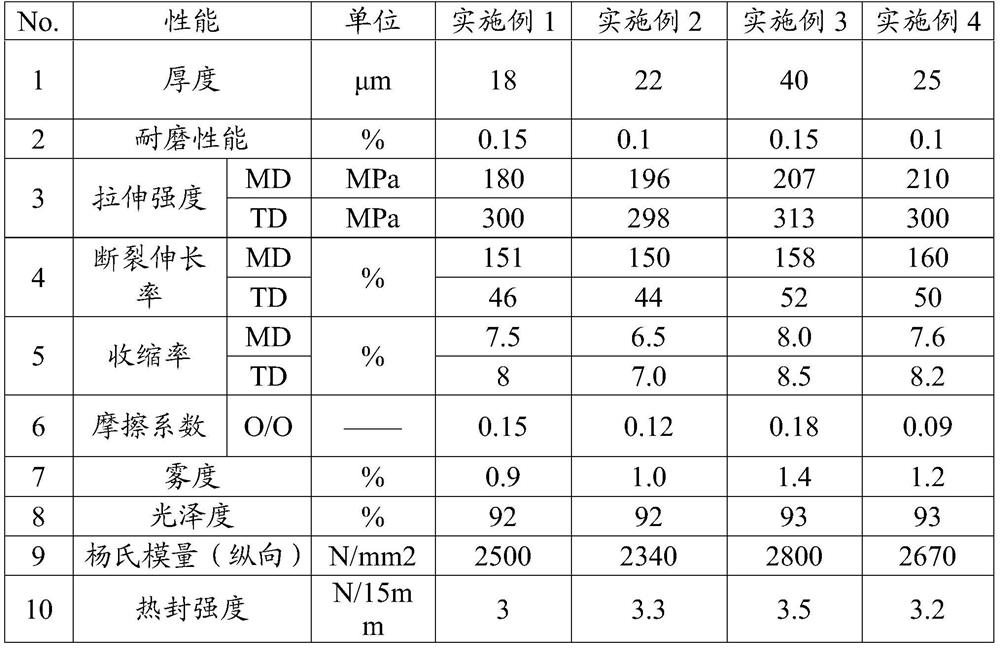

Examples

Embodiment 1

[0094] The thickness of the upper layer is 0.6 μm, and it is prepared from the following raw materials by weight: 76% ethylene-propylene binary copolymer heat-sealing functional masterbatch, 12% silicone polymer, 10% polydimethylsiloxane, 2% Anti-blocking agent; the thickness of the middle layer is 16.6 μm, and it is prepared from the following raw materials by weight: 78% homopolypropylene, 20% petroleum resin, 2% antistatic agent; the thickness of the lower layer is 0.8 μm, made of the following raw materials by weight Formulated as: 93% ethylene-propylene-butadiene terpolymer, 5% polydimethylsiloxane, 2% antiblocking agent. The total thickness is 18 μm.

[0095] The manufacturing method of the above-mentioned ultra-high wear-resistant BOPP film is as follows:

[0096] (1) Ingredients

[0097] The upper, middle and lower layers are mixed according to the above-mentioned weight ratio of raw materials, and the mixing can be done manually or by equipment.

[0098] (2) Extrus...

Embodiment 2

[0109] The thickness of the upper layer is 0.5 μm, and it is prepared from the following raw materials by weight: 74% ethylene-propylene binary copolymer heat-sealing functional masterbatch, 14% silicone polymer, 10% polydimethylsiloxane, 2 % anti-blocking agent; the thickness of the middle layer is 20.7μm, which is made up of the following raw materials by weight: 73% homopolypropylene, 15% petroleum resin, 2% antistatic agent; the thickness of the lower layer is 0.8μm, made of the following weight ratios The raw materials are formulated into: 98% ethylene-propylene-butadiene terpolymer, 2% anti-blocking agent. The total thickness is 22 μm.

[0110] The manufacturing method of the above-mentioned ultra-high wear-resistant BOPP film is as follows:

[0111] (1) Ingredients

[0112] The upper, middle and lower layers are mixed according to the above-mentioned weight ratio of raw materials, and the mixing can be done manually or by equipment.

[0113] (2) Extrusion

[0114] T...

Embodiment 3

[0124] The thickness of the upper layer is 0.7 μm, and it is prepared from the following raw materials by weight: 78% ethylene-propylene binary copolymer heat-sealing functional masterbatch, 10% silicone polymer, 10% polydimethylsiloxane, 2% Anti-blocking agent; the thickness of the middle layer is 38.5μm, which is made up of the following raw materials by weight: 67% homopolypropylene, 30% petroleum resin, 3% antistatic agent; the thickness of the lower layer is 0.8μm, made of the following raw materials by weight Formulated as: 96% ethylene-propylene-butadiene terpolymer, 2% polydimethylsiloxane, 2% antiblocking agent. The total thickness is 40 μm.

[0125] The manufacturing method of the above-mentioned ultra-high wear-resistant BOPP film is as follows:

[0126] (1) Ingredients

[0127] The upper, middle and lower layers are mixed according to the above-mentioned weight ratio of raw materials, and the mixing can be done manually or by equipment.

[0128] (2) Extrusion

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com