Nanocrystalline cellulose/g-C3N4/polyacrylamide composite hydrogel as well as preparation method and application thereof

A technology of nanocellulose and polyacrylamide, applied in water/sludge/sewage treatment, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve hydrogel application limitations, mechanical Poor performance and other problems, achieve good photodegradation performance, enhance mechanical properties, and facilitate recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

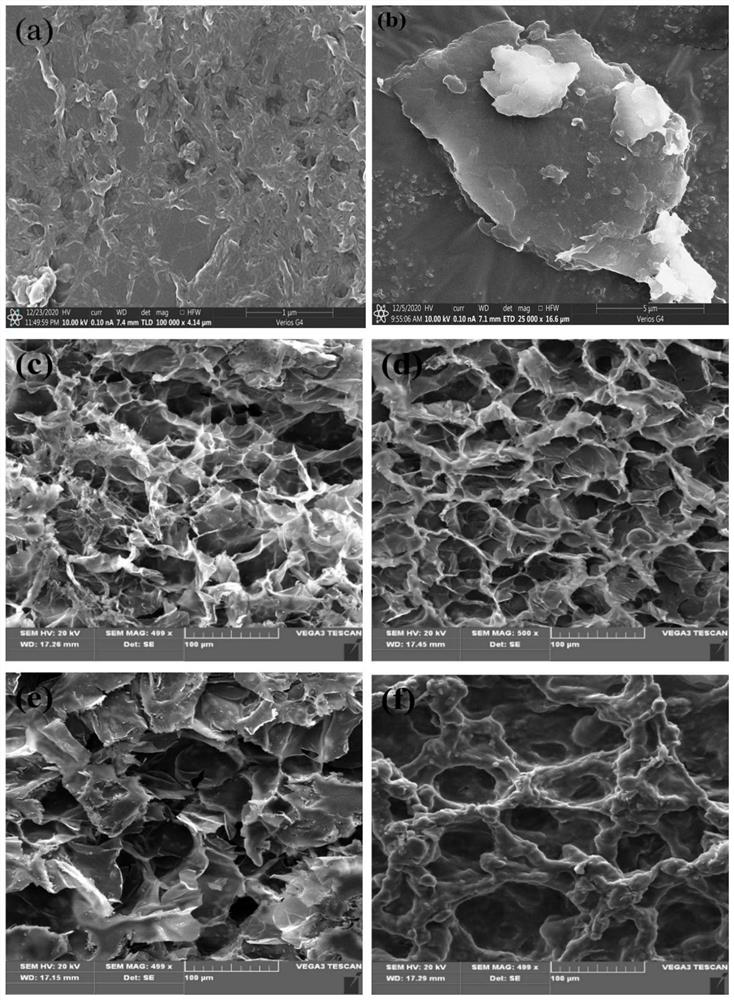

Embodiment 1

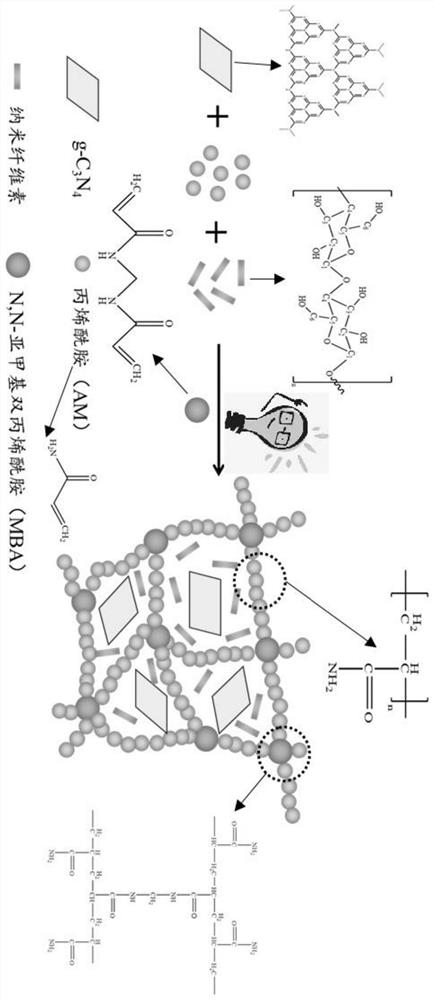

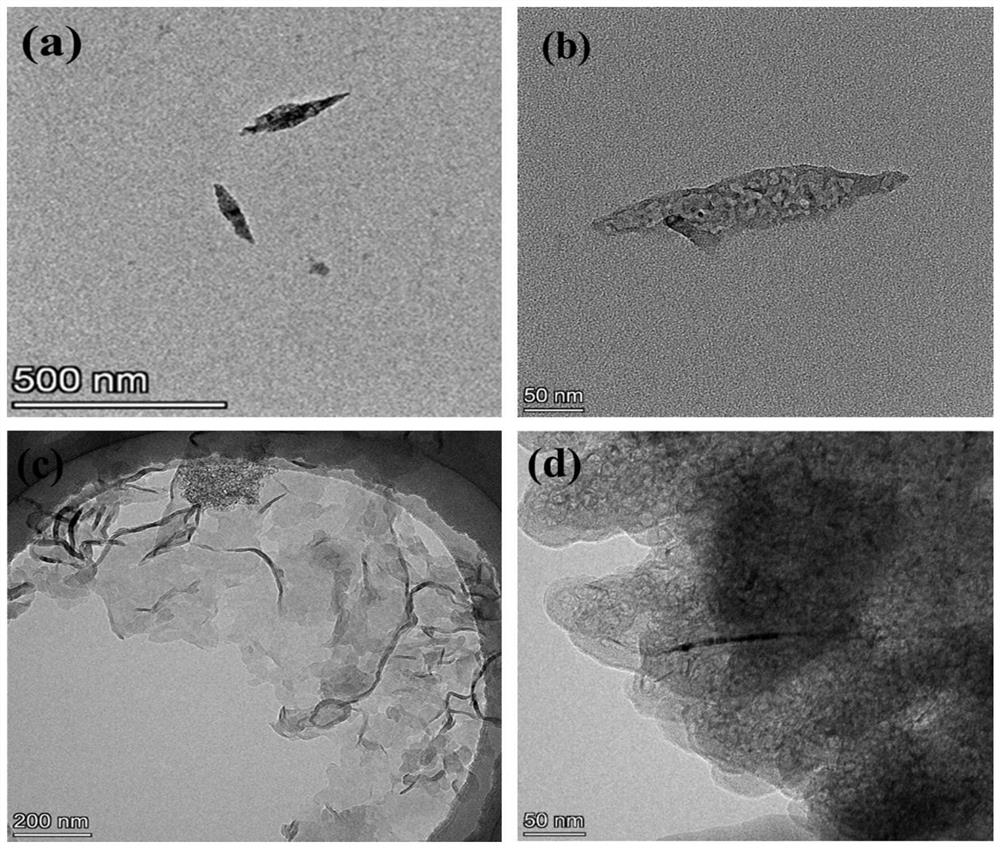

[0037] Step 1. Weigh 0.05g of CNC into a 50ml beaker, add 10ml of ultrapure water, ultrasonicate for 5min to disperse the CNC uniformly, add 0.02g of MBA, continue to ultrasonicate for 5min to dissolve the MBA to obtain a suspension;

[0038] Step 2. Then add 0.001gg-C 3 N 4 Solution in suspension, homogenize at 12000r / min for 15min to make g-C 3 N 4 After uniform dispersion, 1.0 g AM was added, homogenized for 5 minutes, and then sonicated for 10 minutes to obtain a mixed solution;

[0039] Step 3. After illuminating the mixed solution under a 150W xenon lamp for 5 hours, a uniformly formed hydrogel was obtained, and then freeze-dried for 48 hours to obtain nanocellulose / g-C 3 N 4 / polyacrylamide composite hydrogel, denoted as Gel1.

Embodiment 2

[0041] Step 1. Weigh 0.05g of CNC into a 50ml beaker, add 10ml of ultrapure water, ultrasonicate for 5min to disperse the CNC uniformly, add 0.02g of MBA, continue to ultrasonicate for 5min to dissolve the MBA to obtain a suspension;

[0042] Step 2, then add 0.005gg-C 3 N 4 Solution in suspension, homogenize at 12000r / min for 15min to make g-C 3 N 4 After uniform dispersion, 1.0 g AM was added, homogenized for 5 minutes, and then sonicated for 10 minutes to obtain a mixed solution;

[0043] Step 3. After illuminating the mixed solution under a 150W xenon lamp for 5 hours, a uniformly formed hydrogel was obtained, and then freeze-dried for 48 hours to obtain nanocellulose / g-C 3 N 4 / polyacrylamide composite hydrogel, denoted as Gel2.

Embodiment 3

[0045] Step 1. Weigh 0.05g of CNC into a 50ml beaker, add 10ml of ultrapure water, ultrasonicate for 5min to disperse the CNC uniformly, add 0.02g of MBA, continue to ultrasonicate for 5min to dissolve the MBA to obtain a suspension;

[0046] Step 2, then add 0.01gg-C 3 N 4 Solution in suspension, homogenize at 12000r / min for 15min to make g-C 3 N 4 After uniform dispersion, 1.0 g AM was added, homogenized for 5 minutes, and then sonicated for 10 minutes to obtain a mixed solution;

[0047] Step 3. After illuminating the mixed solution under a 150W xenon lamp for 5 hours, a uniformly formed hydrogel was obtained, and then freeze-dried for 48 hours to obtain nanocellulose / g-C 3 N 4 / polyacrylamide composite hydrogel, denoted as Gel3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| photodegradation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com