Production system and production method of high-quality distillate oil

A production system and technology of distillate oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, hydrotreating process, etc., and can solve problems such as high energy consumption, complicated process, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

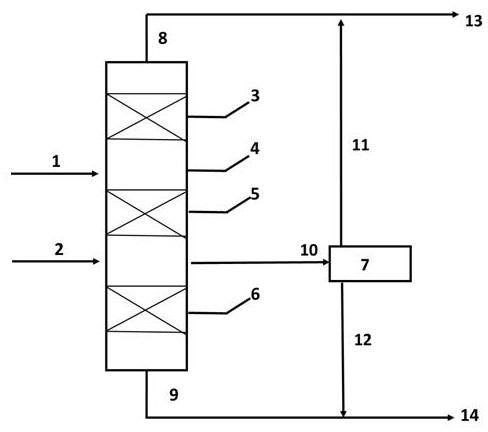

Method used

Image

Examples

Embodiment 1~3

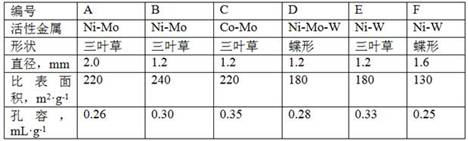

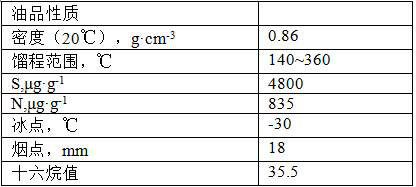

[0026] In this example, a 100mL fixed-bed hydrogenation reactor is used, and a catalyst bed is arranged in the hydrogenation reaction zones I, II, and III from top to bottom. Fill Ni-Mo type hydrofinishing catalyst A in hydrogenation reaction zone Ⅰ, fill Ni-Mo type hydrofinishing catalyst B in hydrogenation reaction zone II, fill Co-Mo type hydrofinishing catalyst B in hydrogenation reaction zone III Catalyst C is filled with 5A molecular sieve in the adsorption separation unit. The catalyst is filled according to the volume ratio of the reactor volume A:B:C=30:40:30, and 100mL of 5A molecular sieve is filled. During the reaction process, the temperature of the reaction bed in each reaction zone is stable and controllable. The properties of the catalyst are shown in Table 1. The raw material oil is kerosene, diesel fuel and coke-diesel mixed oil. The ratio of the three is 40:30:30. The properties of the raw material oil are shown in Table 2. The reaction process conditions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com