Non-woven fabric, preparation method thereof, filter screen and air purifier

A technology of non-woven fabric and filter net, applied in the field of air purification, can solve the problems of air purification to be improved, complex production process, peculiar smell and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

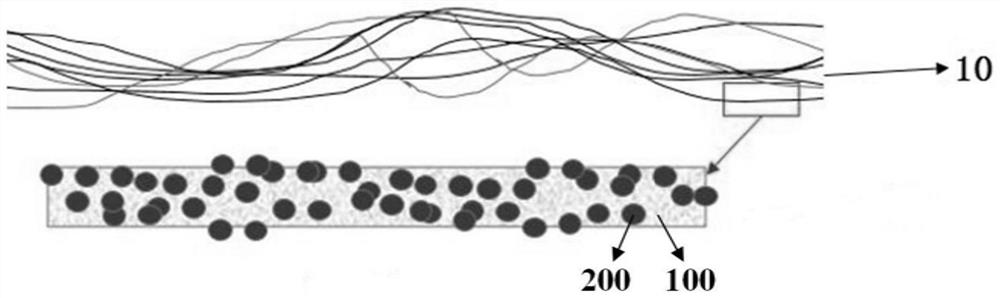

[0055] The non-woven fabric has a plurality of filaments, the plurality of filaments are arranged in a directional or random arrangement, and the plurality of filaments form a network structure; the plurality of filaments include a matrix and catalyst particles, the catalyst particles are distributed on the substrate, and the catalyst particles At least a portion of is embedded in the matrix, wherein,

[0056] The shape of the cross-section of the substrate is circular, the diameter of the substrate is 12 μm, and the linear density is 8tex;

[0057] The catalyst particles are manganese oxides, spherical in shape, with a particle size of 250nm and a specific surface area of 300m 2 / g;

[0058] The weight of the non-woven fabric is 120g / m 2 , the thickness is 0.4mm.

[0059] The non-woven fabric is prepared by melt-spinning 70 parts by weight of polyethylene terephthalate; and 45 parts by weight of the catalyst particles.

[0060] Test the efficiency of this non-woven fabr...

Embodiment 2

[0073] The only difference from Embodiment 1 is that the shape of the cross-section of the base body is circular.

[0074] The efficiency of the non-woven fabric in purifying formaldehyde was tested, and the test result was 89%.

[0075] The air resistance of the non-woven fabric was tested when purifying formaldehyde, and the test result was 1Pa.

[0076] After the non-woven fabric has been used for 6 months, there is no peculiar smell and no powder falling phenomenon.

Embodiment 3

[0078] The only difference from Example 1 is that the diameter of the substrate is 5 μm.

[0079] The efficiency of the non-woven fabric in purifying formaldehyde was tested, and the test result was 93%.

[0080] The air resistance of the non-woven fabric was tested when purifying formaldehyde, and the test result was 4Pa.

[0081] After the non-woven fabric has been used for 6 months, there is no peculiar smell and no powder falling phenomenon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com