Unsupervised machine abnormal sound detection method and device based on single classification algorithm

A detection method, an unsupervised technology, applied in computer parts, neural learning methods, instruments, etc., can solve problems such as unavailability, few abnormal sound samples of equipment, failure types of mechanical equipment failure rates, etc. The detection accuracy and sensitivity are improved, the experimental effect is improved, the mechanical and personal safety and the economic cost are guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

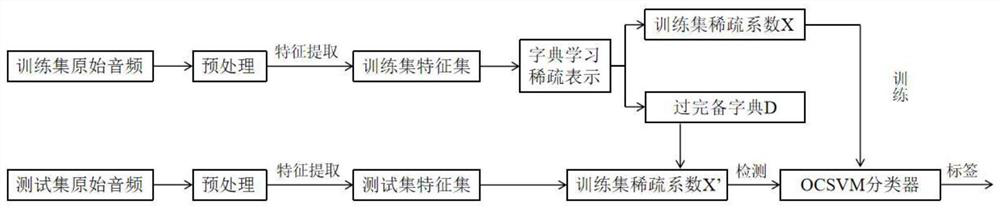

[0044] figure 1 It is a schematic flowchart of an unsupervised machine abnormal sound detection method based on a single classification algorithm in Embodiment 1 of the present invention. see figure 1 , the detection method includes:

[0045] S1. Place a sound collection device next to the equipment to be tested in the operating state, and collect two types of machine sound and audio sample data in the normal operating state and in the abnormal operating state.

[0046] S2. Divide the collected audio sample data to generate two types of audio data sets, a training set and a test set. Wherein, the training set only includes the machine sound audio samples in the normal operation state, and the test set includes both the machine sound audio samples in the normal operation state and the abnormal operation state.

[0047] S3. Perform pre-processing operations such as pre-emphasis, framing, and windowing on the sample data in the training set to obtain several audio frames

[0...

example 1

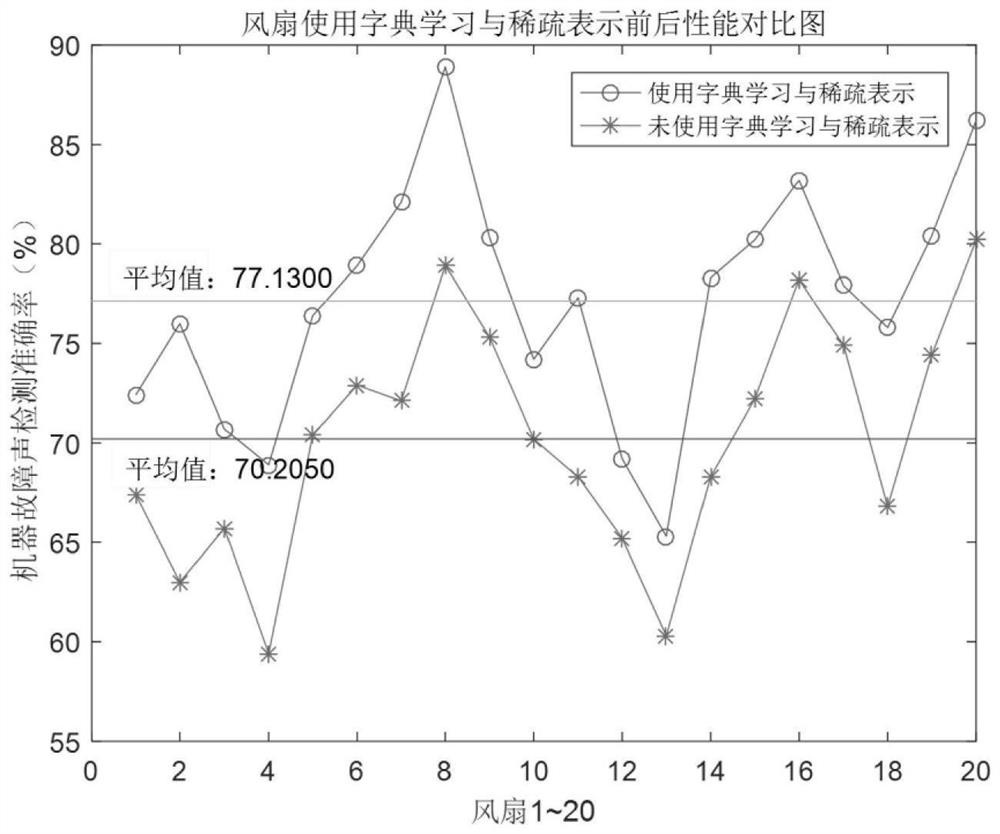

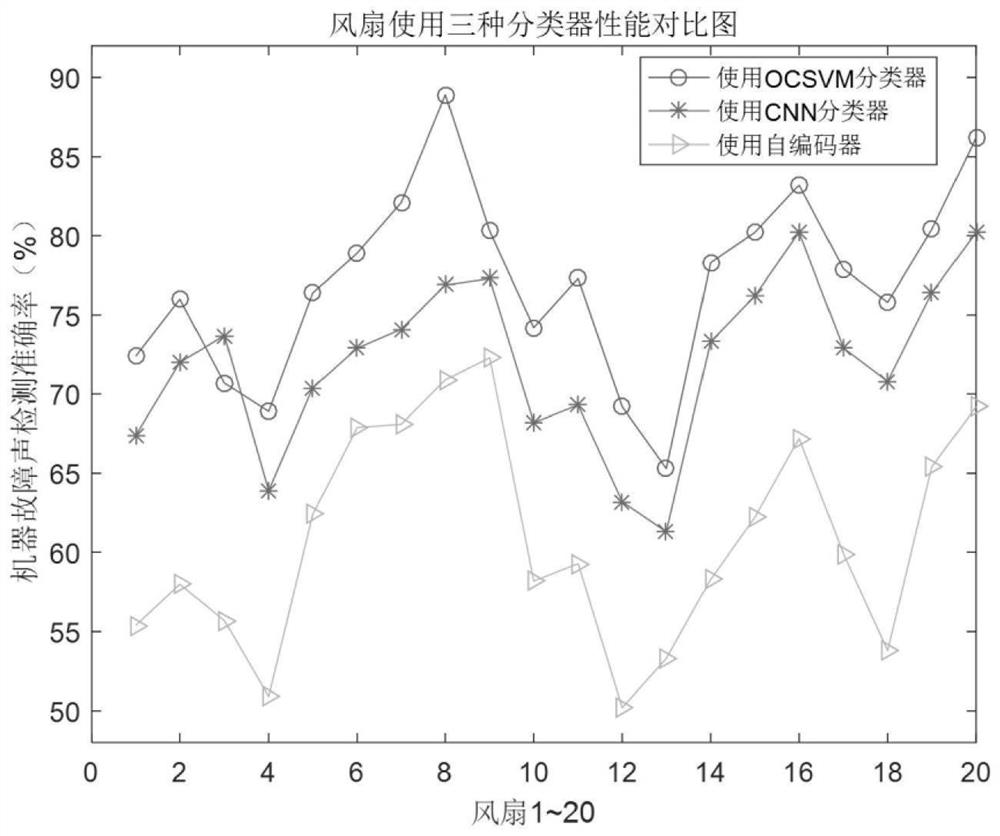

[0053] In the actual test, the present invention has selected a plurality of fans (fan) in the fan factory to carry out the experiment, specifically selected 20 fans in operation, utilized the sound collection device to collect the sound of mechanical operation when they were in operation, and analyzed each The specific operating conditions of each machine are recorded, so as to judge whether the method of the present invention is good or bad for fault sound detection.

[0054] First, use matlab software to pre-emphasize the collected fan data set, select the pre-emphasis coefficient as 0.95, and divide the audio signal into frames and add windows in the time domain. According to the length of the audio, the frame length is set to 20ms, and the Hamming window is selected. , set the length of the window to 1024 points, and the single-hop size to 512 points. Then extract the corresponding characteristic parameters, and select the mean index, variance index, peak index, pulse ind...

example 2

[0056] Belt conveyors are widely used in coal, slag, powder and other production lines due to their advantages such as simple structure, large transportation capacity, strong adaptability, low energy consumption, and long service life. Due to the characteristics of large internal friction and wear of the transported material, some failures often occur in the actual work of the belt conveyor, such as belt deviation, belt tearing, wear, belt softening, scorching and even fire, causing casualties . Through long-term observation and research, it is found that the noise of the belt conveyor is generally very small when it is working normally, and a large abnormal noise will suddenly appear when a fault occurs, which provides inherently favorable conditions for abnormal sound detection. In the present invention, a certain number of auscultation sonars are deployed along the blower to collect the working noise emitted by the equipment, and after a period of sample collection, a train...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com