Surface-mounted thick film fuse structure and manufacturing method thereof

A fuse, surface-mounted technology, applied in the surface-mounted thick-film fuse structure and its manufacturing field, can solve problems such as increasing the rated voltage arc, and achieve the effects of high quality consistency, high reliability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

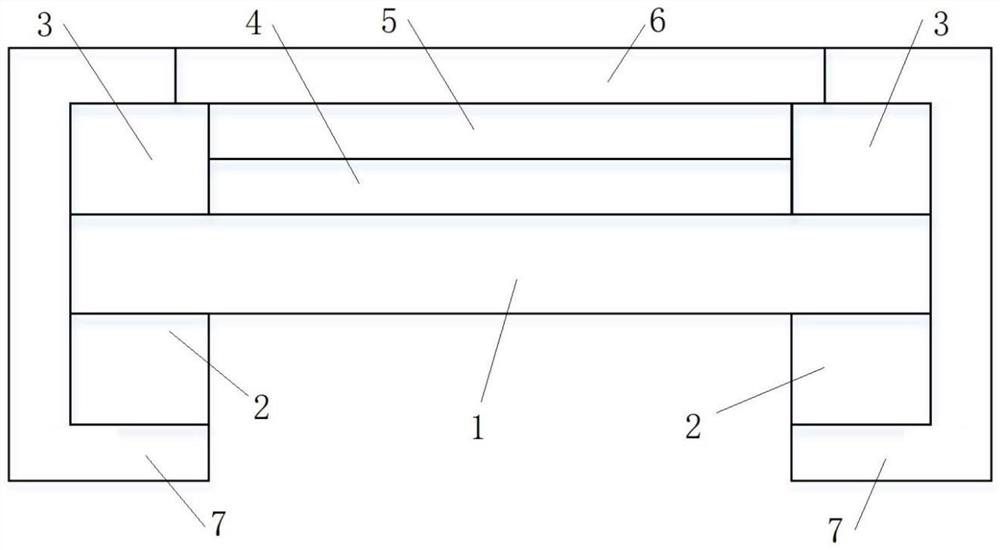

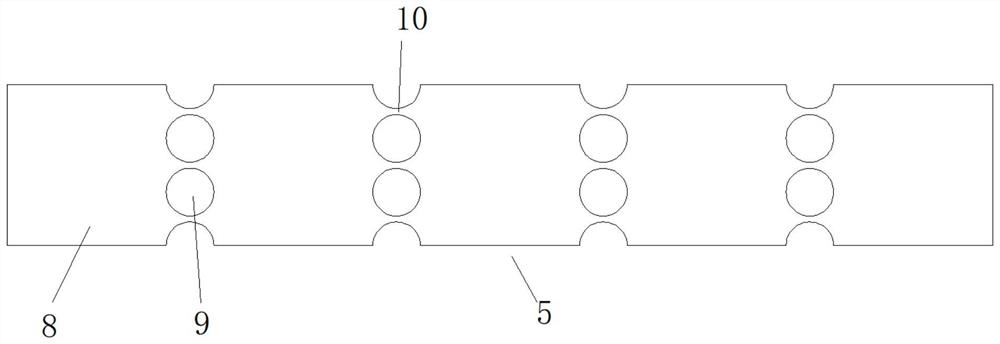

[0037] combine Figure 2 、 Figure 3 The specific implementation of the technical scheme of the invention is as follows:

[0038] (1) Material preparation: a ceramic substrate is selected as a substrate substrate, and according to the arrangement and layout size of fuses, a dicing machine is used to scribe the split lines (i.e., scribe the grooves for splitting individual fuse chips) on the ceramic substrate.

[0039](2) Screen printing a front electrode and a back electrode on the surface of the scribed ceramic substrate, wherein the main components of the front electrode and the back electrode are silver palladium, and the palladium content is 1%-35%.

[0040] (3) preparing a thermal insulation layer on the surface of the ceramic substrate with electrodes, wherein the main component of the thermal insulation layer is silica, the firing temperature of the thermal insulation layer is 850℃ 30℃, and the firing film thickness of the thermal insulation layer is 10μ m ~ 100μ m.

[0041] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com