Printing preparation method and application of single-orientation organic semiconductor crystal patterned array

A technology of organic semiconductors and crystal patterns, applied in semiconductor/solid-state device manufacturing, semiconductor devices, replication/marking methods, etc., can solve the problem of precise control of patterned arrays that are difficult to single orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

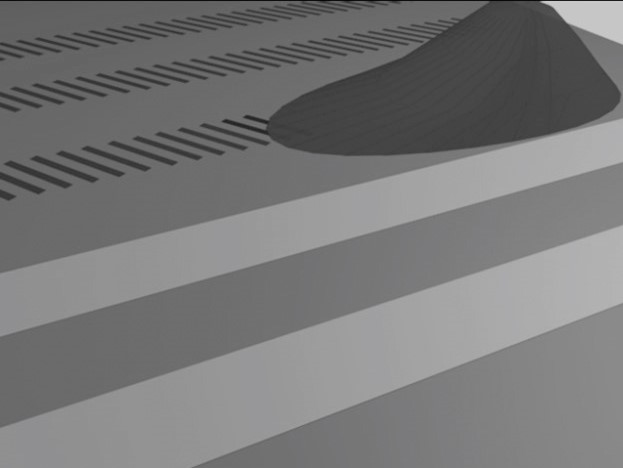

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of pretreatment patterned substrate material

[0050] SiO 2 / Si wafers were ultrasonically cleaned and dried with water, acetone, isopropanol, etc., and lyophilized with phenyltrichlorosilane. The treatment conditions were: vacuum, 4 hours, and 85°C to obtain the isopropylsilyne Lyophilic SiO with static contact angle of 2° in o-dichlorobenzene solution of pentacene (TIPS-PEN) 2 / Si base material.

[0051] The resulting lyophilic SiO 2 Spin-coat a layer of photoresist (SU-8) on the / Si base material, and with the help of a mask, irradiate the surface of the base material with a photoresist film with ultraviolet light, causing a chemical reaction of the photoresist in the exposed area; Then, the photoresist in the unexposed area is dissolved and removed by infiltration and development technology, so that the pattern on the mask plate is copied to the photoresist film, and the SiO with the patterned photoresist is obtained. 2 / Si base material.

[005...

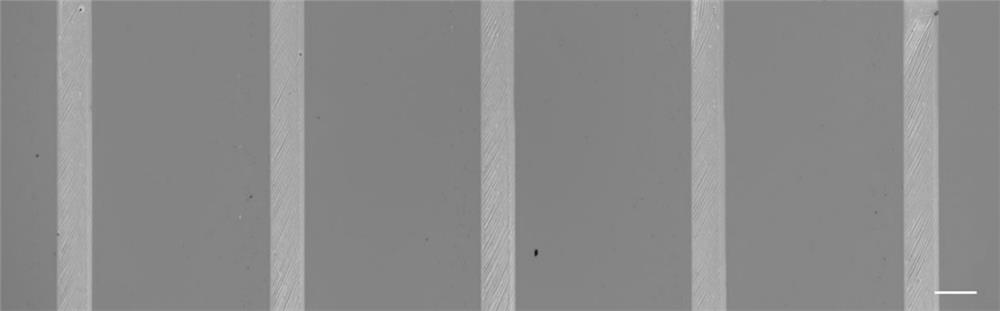

Embodiment 2

[0058] (1) Preparation of pretreated substrate

[0059] SiO 2 / Si wafers were ultrasonically cleaned and dried with water, acetone, isopropanol, etc., and lyophilized with phenyltrichlorosilane. The treatment conditions were: vacuum, 5 h, and 100 °C to obtain the 2,7-bis Octyl[1]benzothieno[3,2-B]benzothiophene (C 8 Lyophilic SiO with a static contact angle of 5° in chlorobenzene solution of -BTBT) 2 / Si base material.

[0060] The resulting lyophilic SiO 2 / Si base material is spin-coated with a layer of photoresist (Z520), and with the help of a mask, the SiO with photoresist film is irradiated with ultraviolet light. 2 / Si base material surface, causing the photoresist in the exposed area to undergo a chemical reaction; then the photoresist in the unexposed area is dissolved and removed by infiltration and development technology, so that the pattern on the mask plate is copied to the photoresist film, and the band is obtained. SiO with photoresist patterning 2 / Si bas...

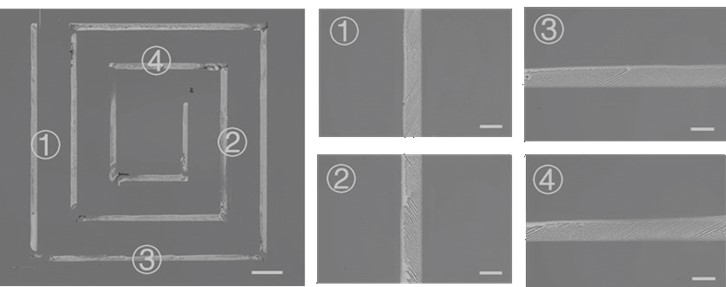

Embodiment 3

[0067] (1) Preparation of pretreated substrate

[0068] SiO 2 / Si wafers were ultrasonically cleaned and dried with water, acetone, isopropanol, etc., and lyophilized with phenyltrichlorosilane. The treatment conditions were: vacuum, 2 hours, and 65°C. Lyophilic SiO with a static contact angle of 30° in ether solution 2 / Si base material.

[0069] The resulting lyophilic SiO 2 / Si base material is spin-coated with a layer of photoresist (HSQXR-1541-006), and with the help of a mask, irradiate the SiO with photoresist film with ultraviolet light 2 / Si base material surface, causing the photoresist in the exposed area to undergo a chemical reaction; then the photoresist in the unexposed area is dissolved and removed by infiltration and development technology, so that the pattern on the mask plate is copied to the photoresist film, and the band is obtained. SiO with photoresist patterning 2 / Si base material.

[0070] The SiO with photoresist pattern 2 The / Si substrate ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com